Method for weaving polyamide bag fabrics

A technology of luggage fabrics and nylon, which is applied in textiles, papermaking, fabrics, textiles, etc., can solve problems such as high prices, low yields, and complicated processes, and achieve the effect of reducing weaving costs and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

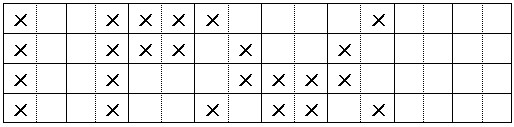

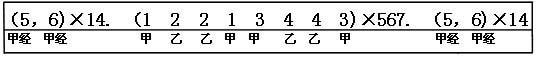

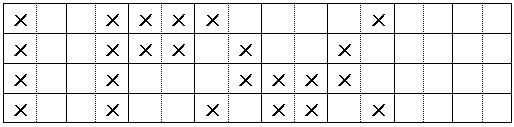

[0013] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0014] as attached figure 1 And attached figure 2 As shown, a weaving method of nylon luggage fabric, weaves two kinds of warps of different thicknesses through a double-jet single warp beam loom, adopts 2 nylon FDY and adds 200T / M Z twist as the nail warp after merging, and uses 4 warps After merging nylon FDY, add 200T / M Z twist as the second warp; when debugging on the loom, adjust the loom to make the tension of the first warp and the second warp consistent;

[0015] Nail warp: 210D / 24F × 2 nylon FDY semi-gloss 200T / M Z twist

[0016] Second classic: 210D / 24F × 4 nylon FDY semi-gloss 200T / M Z twist

[0017] A weft: 210D / 24F × ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com