Method for correcting welding deformation of large plate-type structural piece

A technology of welding deformation and structural parts, which is applied in the field of correction of welding deformation of large-scale plate-shaped structural parts, to achieve the effect of meeting the requirements of correction accuracy, saving investment, and reducing operation level requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] The technical solution of the present invention will be further described in detail below through specific embodiments.

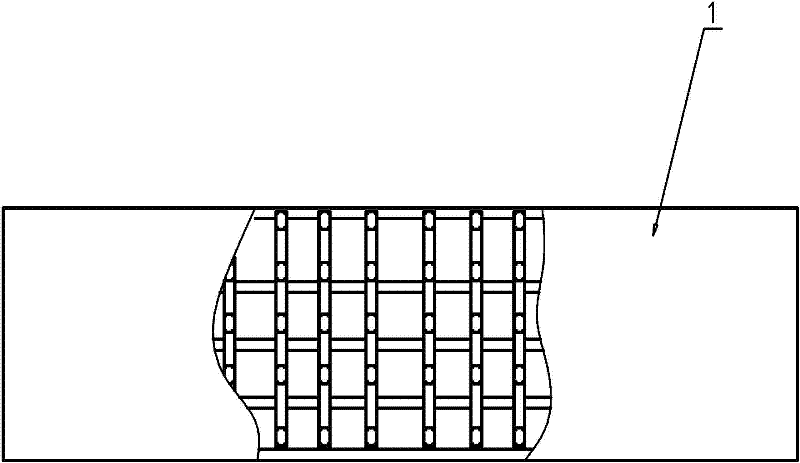

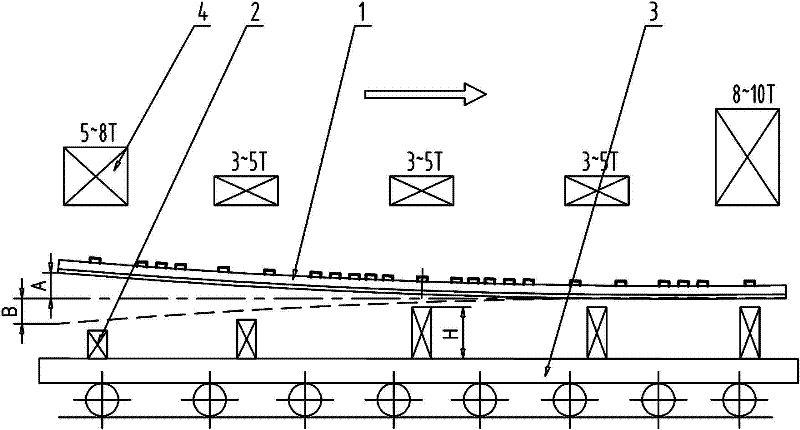

[0037] Taking the correction of a hydraulic platform as an example, the workpiece 1, the platform, is the main load-bearing component of the hydraulic platform, and its maximum external dimensions (length × width × height) are 11000 × 3500 × 115mm. It is a dense hollow rectangular steel frame with continuous welding seams. Sticking and welding a whole piece of t35mm steel plate (machined to t30mm after welding), is a typical "plate-shaped structural part". Such as figure 1 , figure 2 shown in . The precision requirements of the entire plane after processing are flatness ≤ 1.5mm, parallelism between the upper and lower sides of the platform ≤ 0.5mm, and the thickness difference of the upper flat steel plate (t30mm) ≤ 3mm. If the above requirements cannot be guaranteed, it will bring unstable factors to the installation and use of the whole platfor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap