Three-drive extensible dexterous mechanical arm

A manipulator, three-drive technology, applied in manipulators, program-controlled manipulators, joints, etc., can solve the problems of unfavorable energy saving, increase the structural complexity of space manipulators, increase the mass and moment of inertia of space manipulators, and achieve structural Compactness, high degrees of freedom, and overall light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

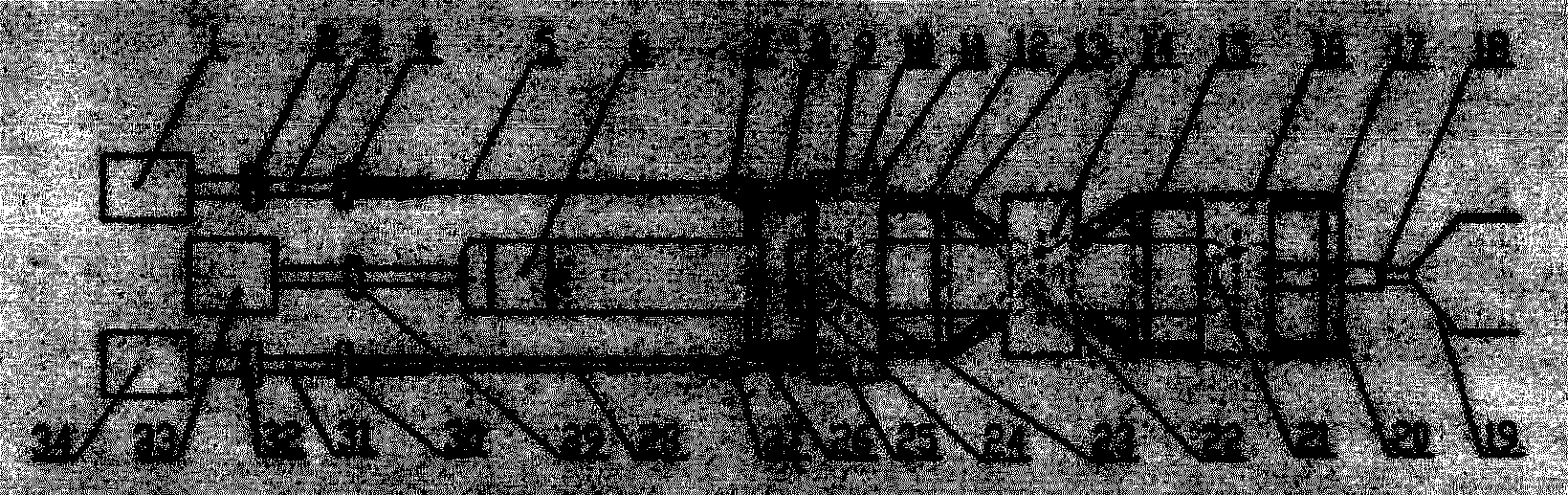

[0034] The structure of the mechanical arm will be further described below in conjunction with the accompanying drawings.

[0035] Such as figure 1 , 2 As shown, three driving units 1, 33, 34 provide power for the entire mechanical arm, wherein the output ends of the driving units 1, 34 are respectively connected with the lead screws 3, 31 through the couplings 2, 32; the lead screws 3, 31 Lead screw nuts 4, 30 are respectively installed on the top, and lead screw nuts 4, 30 are respectively connected with push rods 5, 28, which can push the push rods to do reciprocating linear motion; 26 is connected with the outer wall of the deflection ring 10. Through the sliding of the lead screw nuts 4 and 30, the push rods 5 and 28 are pushed respectively, and the force transmission of the connecting rods 8 and 26 can control the deflection of the deflection ring 10; the output end of the drive unit 33 is connected to the The first joint input end 6 is connected to drive the first jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com