A coupler secondary buffer device

A secondary buffer and coupler technology, applied in the field of vehicles, can solve the problems of shortening the service life of the coupler buffer device and increasing the coupler force, and achieves the effect of eliminating idle travel and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

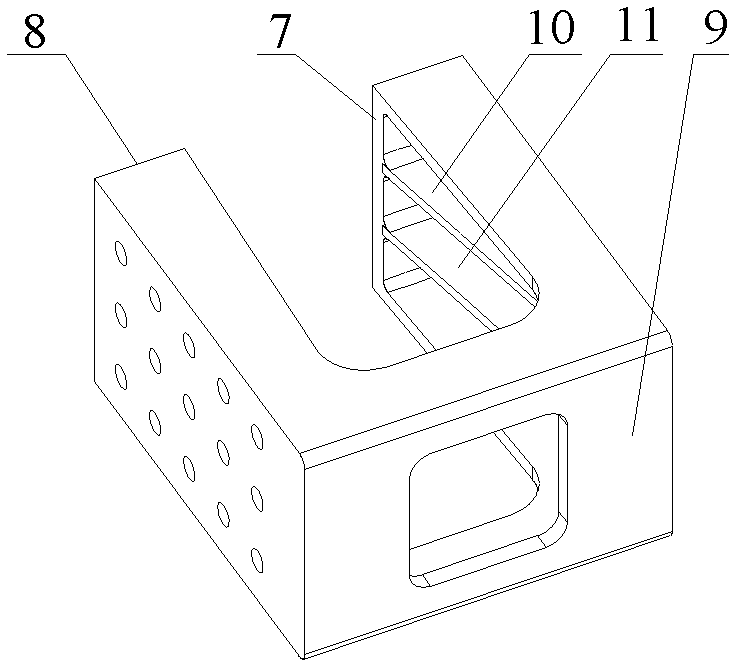

[0034] See attached figure 1 , in the coupler secondary buffer device provided by Embodiment 1 of the present invention, the rear slave plate seat includes the first baffle plate 7, the second baffle plate 8 and the third baffle plate 9, the first baffle plate 7, the second baffle plate 8 and the An inner chamber is formed between the third baffles 9 . In the cavity between the first baffle 7 and the third baffle 9 and in the cavity between the second baffle 8 and the third baffle 9, the first rib 10 and the second rib 11 are arranged respectively. , so that the inner cavity between the first baffle plate 7 and the third baffle plate 9 and the inner cavity between the second baffle plate 8 and the third baffle plate 9 are divided into three parts respectively. Wherein, in the inner cavity, the one between the first rib plate 10 and the second rib plate 11 is the middle cavity, and the one outside the first rib plate 10 and the second rib plate 11 are side cavities.

[0035] ...

Embodiment 2

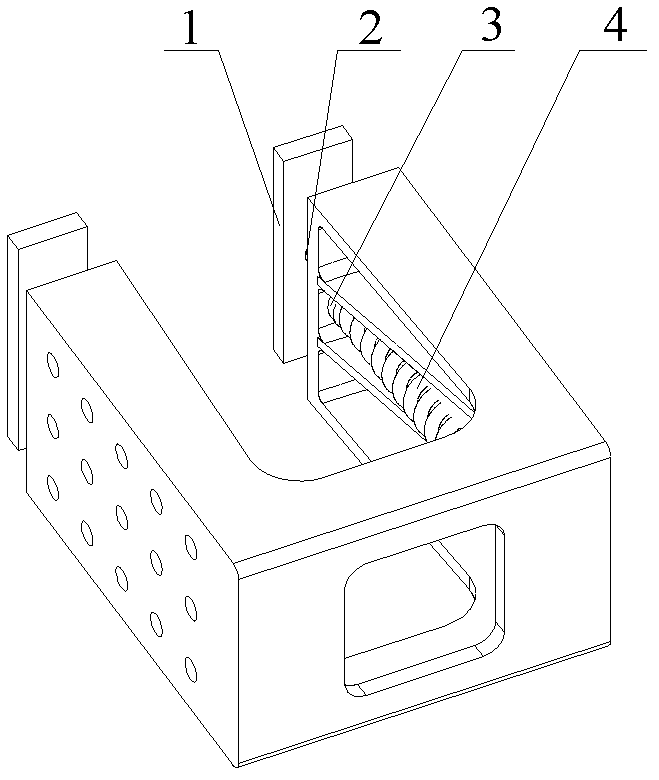

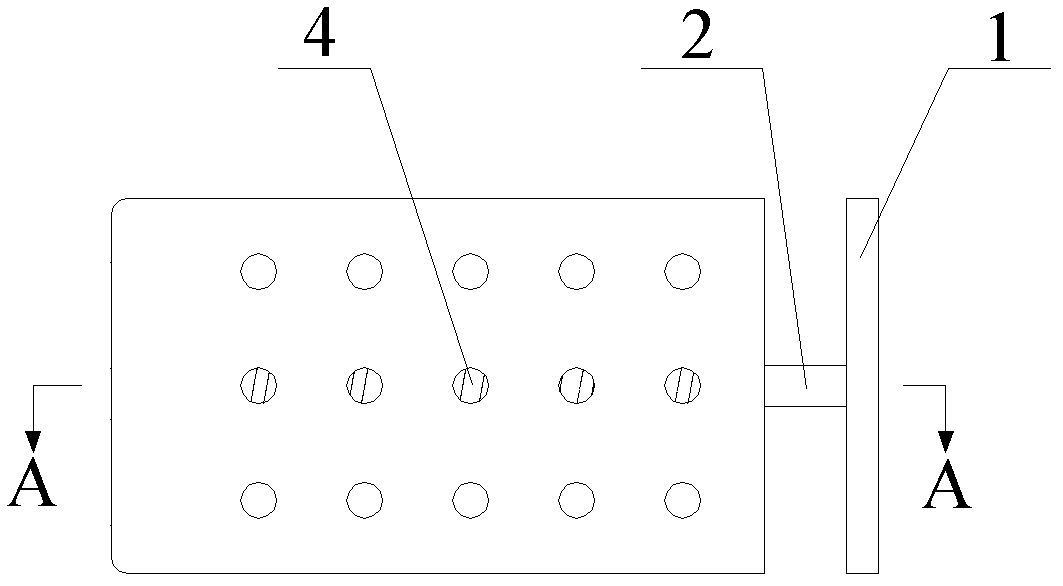

[0040] See attached Figure 5 ~ attached Figure 7, as a preferred technical solution of Embodiment 1, a pair of second through holes are provided on the third baffle plate 9 at positions corresponding to the first through holes;

[0041] See attached Figure 7 , The second buffer section includes a push rod 2, a gasket 3, a guide rod 5, an elastic component and a locking component. In this embodiment, the elastic component is a spring 4, and the locking component is a nut 6. The buffer baffle 1 is fixedly connected to one end of the push rod 2, the push rod 2 passes through the first through hole, the other end of the push rod 2 is fixedly connected to one side of the gasket 3, and the other side of the gasket 3 is fixedly connected to the guide rod 5, the other end of the guide rod 5 protrudes from the second through hole, the protruding end of the guide rod 5 is locked by the nut 6, the spring 4 is sleeved on the guide rod 5, and one end of the spring 4 is against the was...

Embodiment 3

[0044] As a preferred technical solution of Embodiment 1, two pairs of first-type through holes symmetrical to each other are opened on the first baffle plate 7 and the second baffle plate 9 at positions corresponding to the side cavities, and the first buffer baffle plate The 1st and 2nd buffer baffles are respectively connected with the first type of buffer section through the first type of through holes.

[0045] When using the coupler secondary buffer device provided by Embodiment 3 of the present invention, in addition to the beneficial effects of the coupler secondary buffer device provided by Embodiment 1, since the first type of buffer joints increases from one pair to two pairs, the buffering effect Can be played better, and the size of the cushioning force that can be applied is greater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com