Material stirring device

A mixing device and material technology, applied in roads, road repairs, roads, etc., can solve the problem that materials cannot be fully mixed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

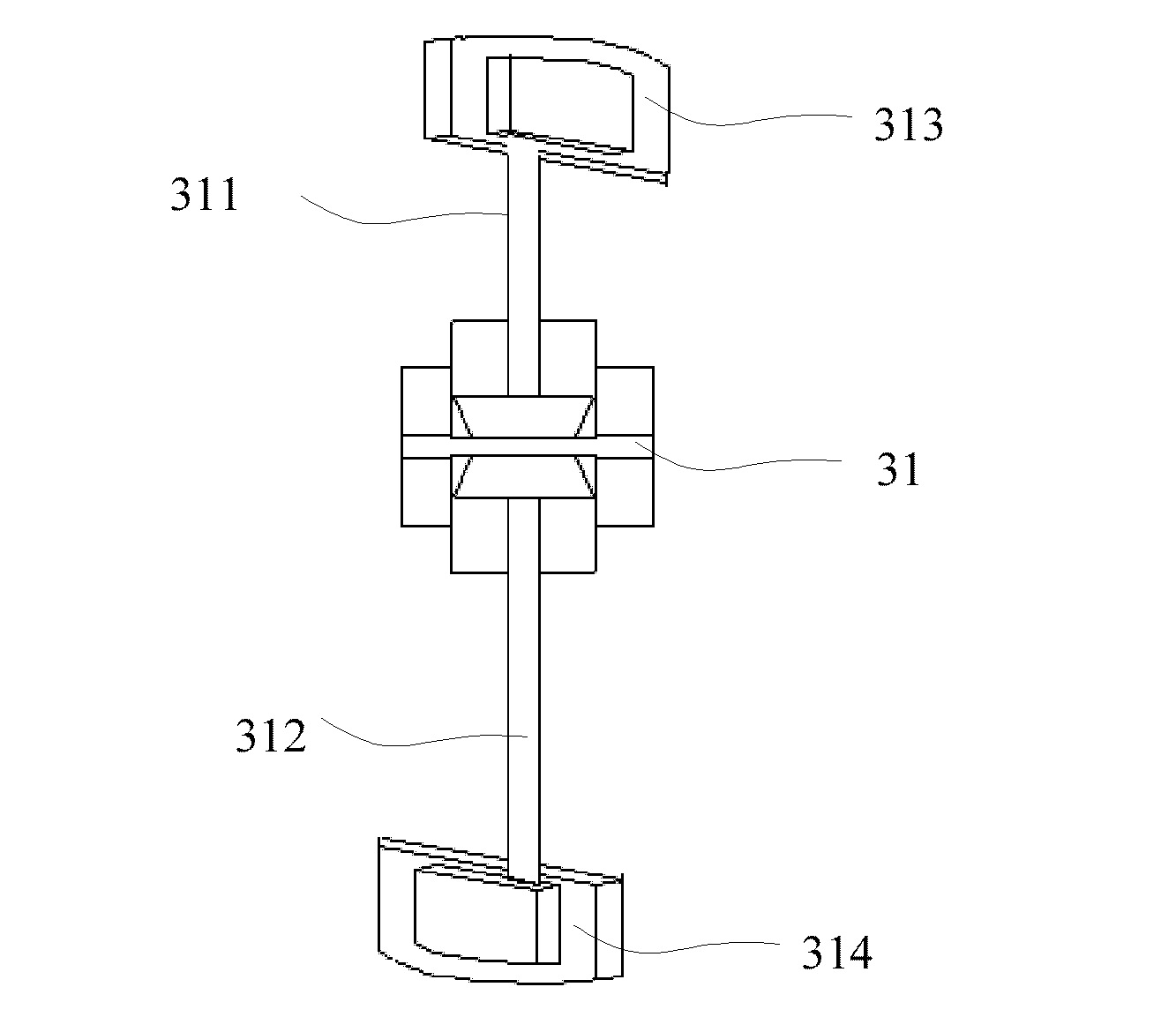

[0044] In order to fully stir the materials in the vicinity of the stirring shaft, the present invention provides a material stirring device, which includes a stirring shaft 31 and multiple groups of stirring units installed on the stirring shaft in sequence along the axial direction. Stirring unit structure such as image 3 As shown, each stirring unit includes at least one stirring arm 311 on the stirring shaft, the stirring arm is provided with stirring blades, and the distance between at least two stirring blades 313, 314 and the stirring shaft 31 is different. In this material stirring device, because there are at least two stirring blades 313 and 314 and the distance between the stirring shaft is different, therefore, the different stirring blades with the distance between the stirring shaft can make the center of the stirring shaft in the material stirring device Materials in both near and far areas can be thoroughly mixed. The material mixing device can be used in mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com