High-performance waterproof fireproof external thermal insulating decorative board and manufacturing process

An external thermal insulation, high-performance technology, applied in covering/lining, building, building structure, etc., can solve the problems of high rebound stress of products, warping of board surface, troublesome construction, etc. The effect of improved damage strength and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

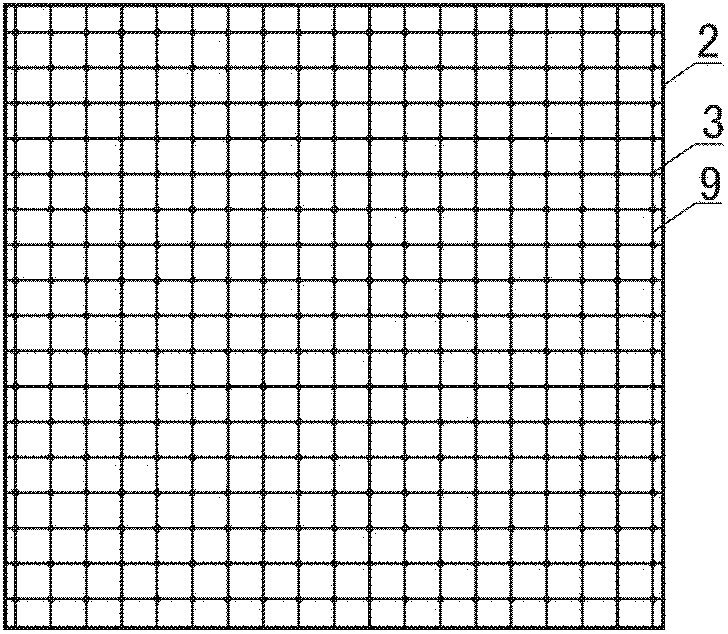

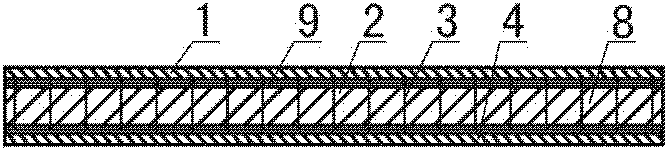

[0021] Such as figure 1 — image 3 As shown, the high-performance waterproof and fireproof external thermal insulation decorative board in the present invention comprises a thermal insulation layer 2, a finish layer 1 and a wall layer 4, and one side of the thermal insulation layer 2 ( image 3 in the upper side) with the finish layer 1 side ( image 3 The bottom of the middle) face-to-face contact connection, the other side of the insulation layer 2 ( image 3 The bottom of the middle) and the side of the wall layer 4 ( image 3 The top of the middle) face-to-face contact connection, the wall layer 4 is a non-combustible material layer; the insulation layer 2 includes a non-combustible fiber layer 8, a non-combustible cover layer 9 and a non-combustible drawstring 3, and the non-combustible cover layer 9 is distributed on both sides of the non-combustible fiber la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com