A Design Method of Recycled Concrete Composite Self-Insulation Block

A technology of recycled concrete and self-insulating blocks, which is applied to ceramic products, manufacturing tools, sustainable waste treatment, etc., to achieve the effects of good scalability, good energy saving and environmental protection benefits, economic benefits, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

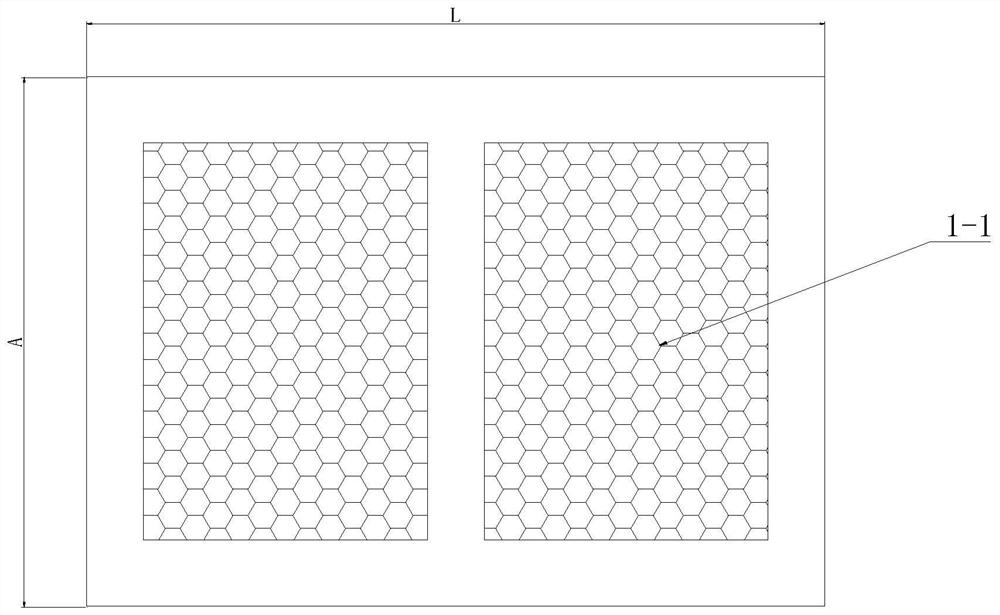

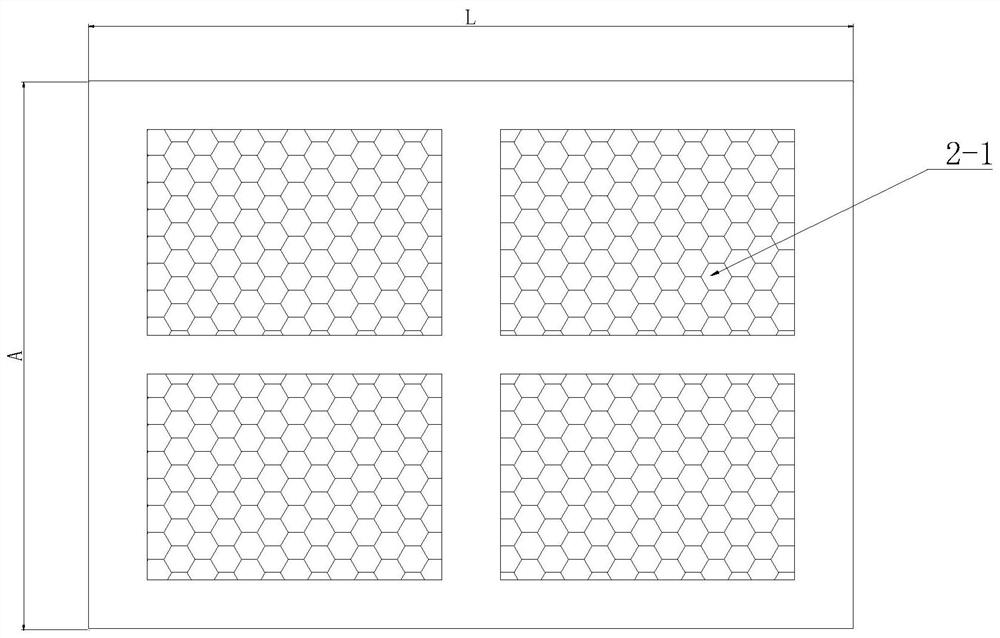

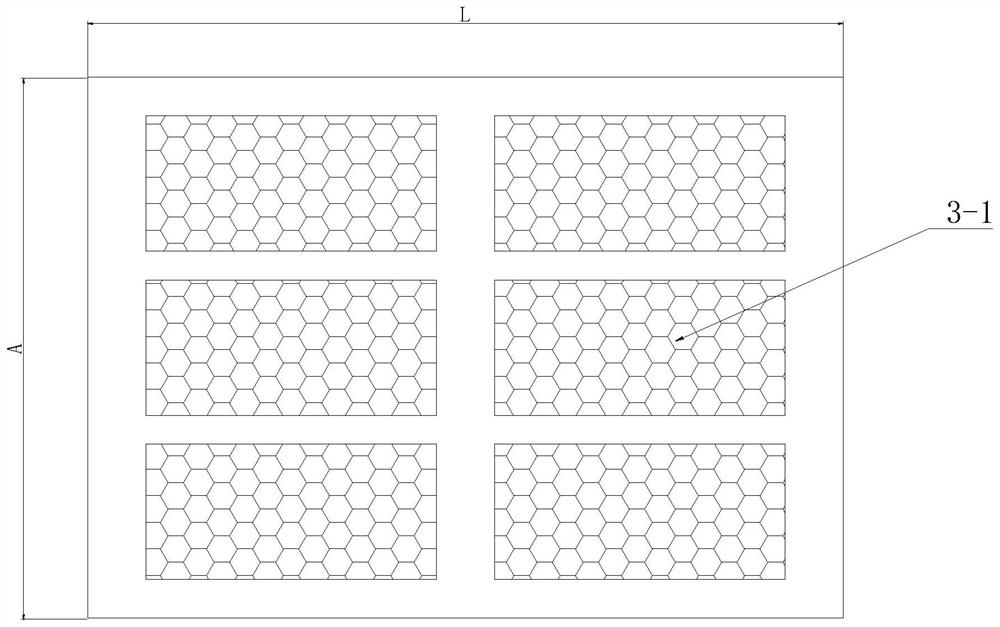

[0093] Such as Figure 1a to Figure 1h and figure 2 A design method of the shown recycled concrete composite self-insulation block comprises the following steps:

[0094] Step 1. Setting of recycled concrete composite self-insulating block parameters:

[0095] Step 101, setting the recycled concrete composite self-insulating block as a cuboid; wherein, the length of the recycled concrete composite self-insulating block is L, and the width of the recycled concrete composite self-insulating block is the recycled concrete composite self-insulating block The thickness is A, and the height of the recycled concrete composite self-insulating block is H;

[0096] Step 102, setting the recycled concrete composite self-insulating block to be provided with a through hole; wherein, the cross section of the through hole is rectangular;

[0097] Step 103, setting the porosity K of the recycled concrete composite self-insulating block x 57.7%;

[0098] Step 104, set the width of the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com