Clamping and opening/closing linkage mechanism for chain-clamp material discharging

A technology of linkage mechanism and chain clip, applied in the direction of electrical components, electrical components, etc., can solve the problems of increasing the investment and operating cost of plug-in machine equipment, complex structure of the head mechanism of the plug-in machine, and the performance of the plug-in machine is not stable enough, and achieves practicability. Strong, obvious progress, the effect of reducing the difficulty of processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

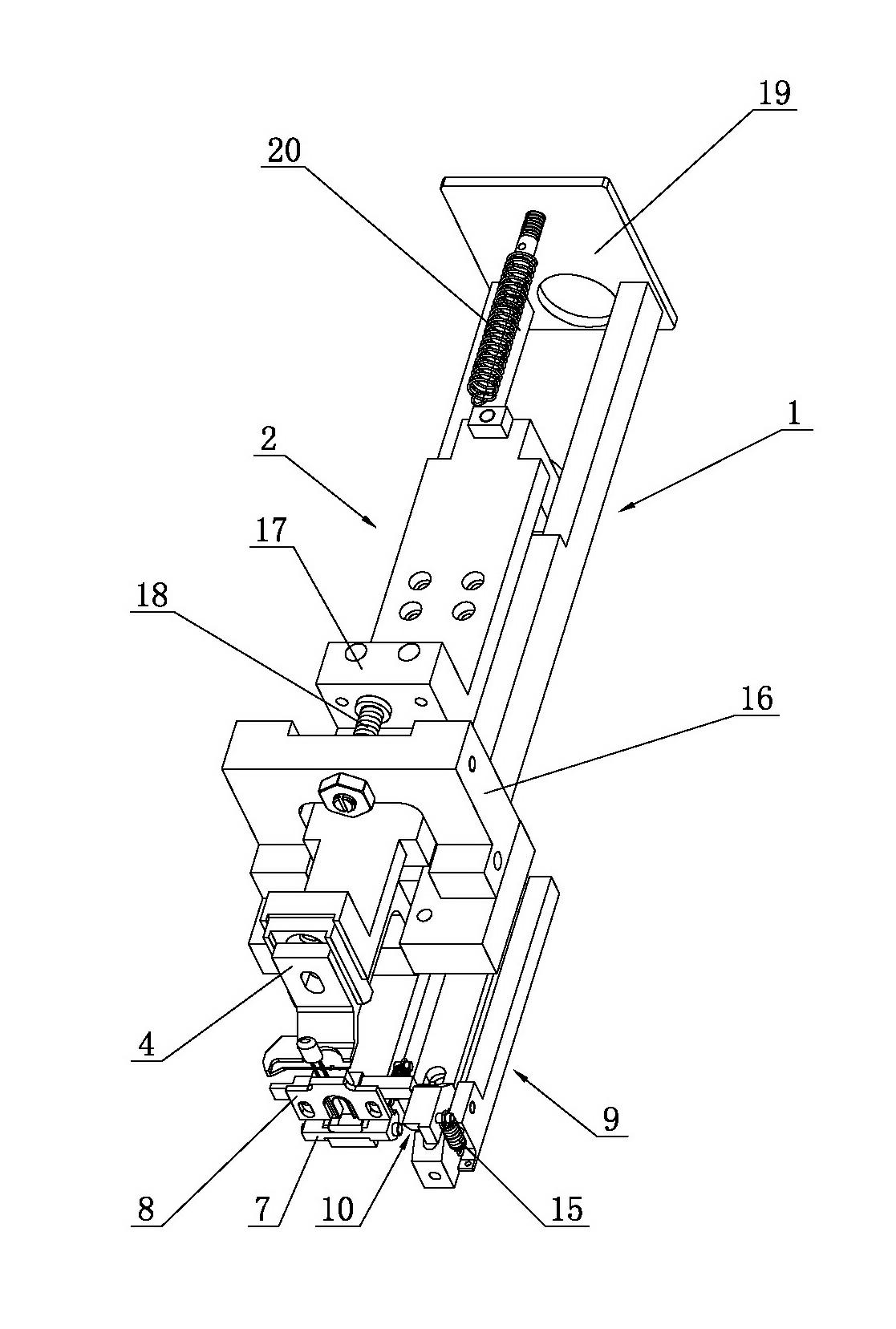

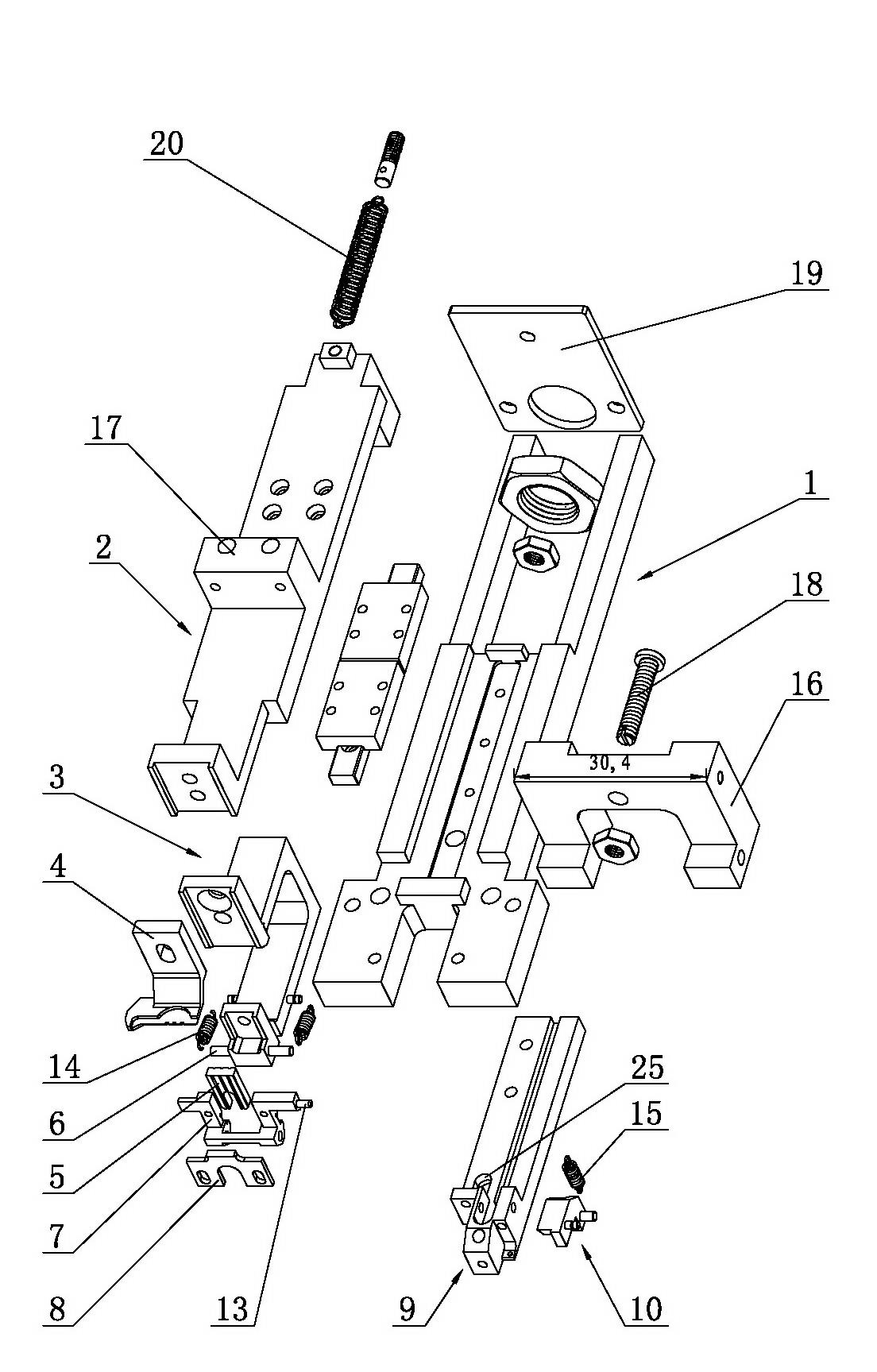

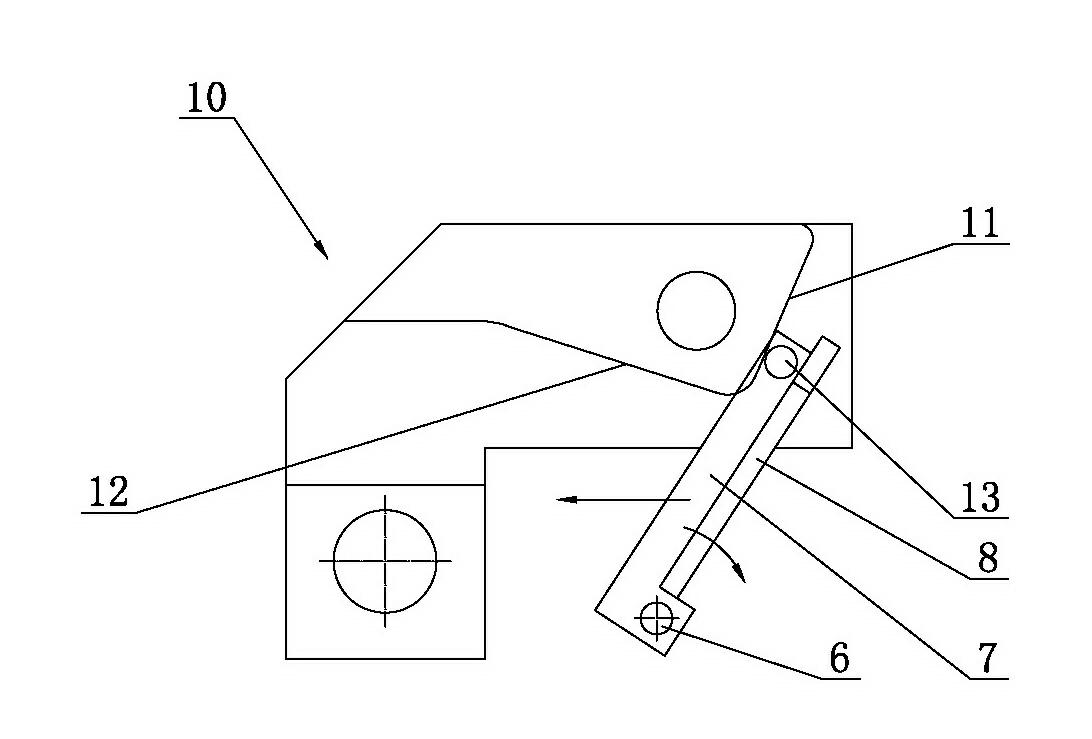

[0026] Such as Figure 1 to Figure 6 Shown is the first embodiment of the opening and closing linkage mechanism of the chain clip unloading and clamping of the present invention, including the feeding base 1, the feeding guide rod 2 movably installed on the feeding base 1 and the front end of the feeding guide rod 2 U-shaped frame 3, the upper end of the U-shaped frame 3 is equipped with a pushing block 4, and the lower end of the U-shaped frame 3 is equipped with a feeding slot 5; the lower end of the U-shaped frame 3 is provided with a hinge pin 6. The hinge pin 6 is equipped with a clamping bracket 7, and the clamping bracket 7 is equipped with a clamping piece 8, and the clamping piece 8...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap