Detoxification curing technology for whole-grain soybeans

A soybean and curing technology, applied in the field of whole soybean detoxification and curing technology, can solve the problems of gastrointestinal discomfort, inability to completely remove soybean toxins, indigestion, etc., and achieve the effect of broad industry prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

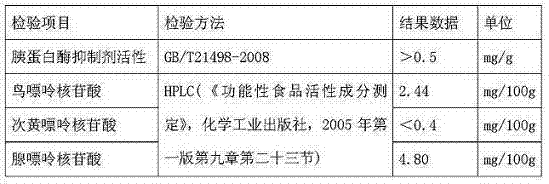

Image

Examples

Embodiment 1

[0011] Put 100 kg of whole soybeans in a polishing machine for polishing treatment, put them into a distillation tank under normal pressure in a dry state, heat and distill, set a steam source (evaporator) next to the distillation tank, and pipe the distillation tank Connect with the evaporator, add 2 kg of ethanol with a concentration of 50% to the water to be evaporated in the evaporator and heat it, and distill for 5 minutes; then add 0.01 kg of acetic acid with a concentration of 3% to the mixed liquid in the evaporator, Distill soybeans for 20 minutes; then add 0.001 kg of ethanol with a concentration of 50% to the mixed liquid in the evaporator, and then distill for 5 minutes. The soybeans are taken out from the retort, vacuum-packed, and shipped.

Embodiment 2

[0013] Put 100 kg of whole soybeans in a polishing machine for polishing treatment, put them into a distillation tank under normal pressure in a dry state, heat and distill, set a steam source (evaporator) next to the distillation tank, and pipe the distillation tank Connect with the evaporator, add 5 kg of ethanol with a concentration of 50% to the water to be evaporated in the evaporator and heat it, and distill for 5 minutes; then add 5 kg of acetic acid with a concentration of 3% to the mixed liquid in the evaporator, Distill soybeans for 30 minutes; then add 0.015 kg of ethanol with a concentration of 50% to the mixed liquid in the evaporator, and distill for another 5 minutes. The soybeans are taken out from the retort, packed in non-vacuum, and shipped out.

Embodiment 3

[0015] Put 100 kg of whole soybeans in a polishing machine for polishing treatment, put them into a distillation tank under normal pressure in a dry state, heat and distill, set a steam source (evaporator) next to the distillation tank, and pipe the distillation tank Connect with the evaporator, add 3 kg of ethanol with a concentration of 50% to the water to be evaporated in the evaporator and heat it, and distill for 5 minutes; then add 3 kg of acetic acid with a concentration of 3% to the mixed liquid in the evaporator, Distill soybeans for 10 minutes; then add 0.01 kg of ethanol with a concentration of 50% to the mixed liquid in the evaporator, and then distill for 1 minute. The soybeans are taken out from the retort, vacuum-packed, and shipped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com