Keyhole repairing welding method for friction stir welding of thick plate aluminum alloy

A friction stir welding and aluminum alloy technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as cracks, and achieve the effect of solving cracks and reducing product scrap rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

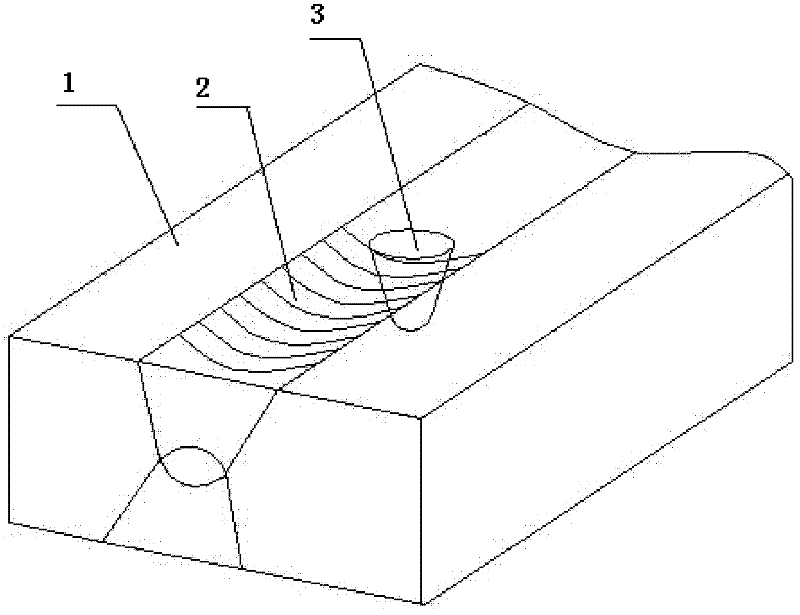

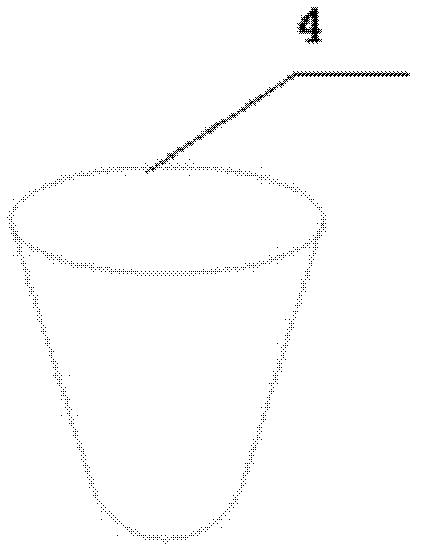

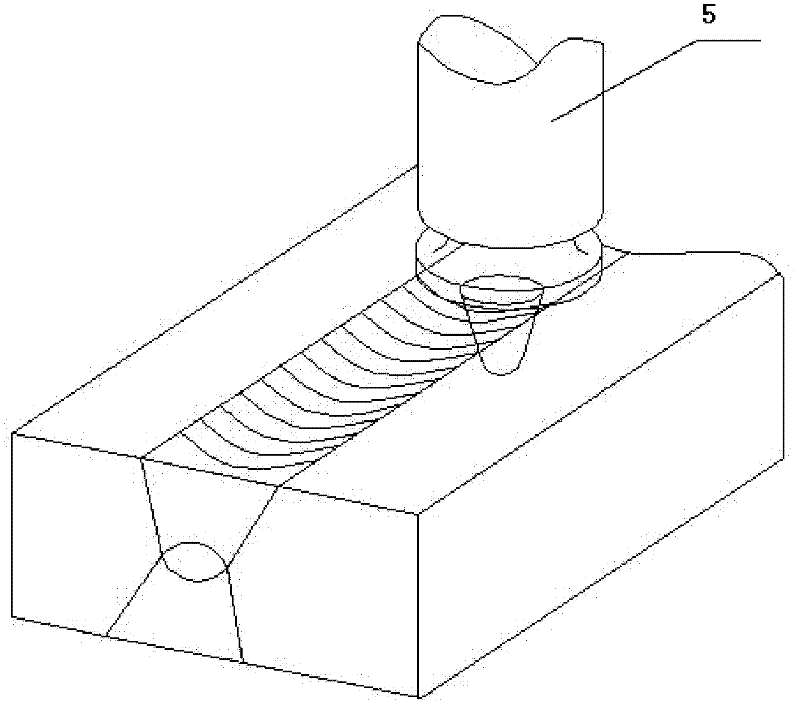

[0011] refer to figure 1 , figure 2 , image 3 , after the keyhole 2 appears during the welding process of the 10mm thick plate part 1, fill the keyhole position with a filling plug 4 of the same quality as the base material, whose shape and size match the keyhole, and then choose a speed of 1200 rpm after filling / min; the friction stir welding welding head 5 with a welding speed of 600mm / min performs secondary repair welding, and 3 is the weld seam. After tensile test analysis, the tensile strength is 185MPa; the metallographic analysis of the microstructure is qualified.

Embodiment 2

[0013] 25mm thick plate parts, friction stir welding process: rotating speed 900 rpm; welding speed 400mm / min. After tensile test analysis, the tensile strength is 175MPa; the metallographic analysis of the microstructure is qualified.

Embodiment 3

[0015] 35mm thick plate parts, friction stir welding process: speed 720 rpm; welding speed 180mm / min. After tensile test analysis, the tensile strength is 170MPa; the metallographic analysis of the microstructure is qualified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com