Apron board locking failure protection device and bullet train

A failure protection and skirt lock technology, which is applied to railway car bodies, transportation and packaging, railway car body parts, etc., can solve the problems of skirt board damage, skirt board thickness limitation, inconvenient installation of locks, etc., to avoid damage, Operational safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

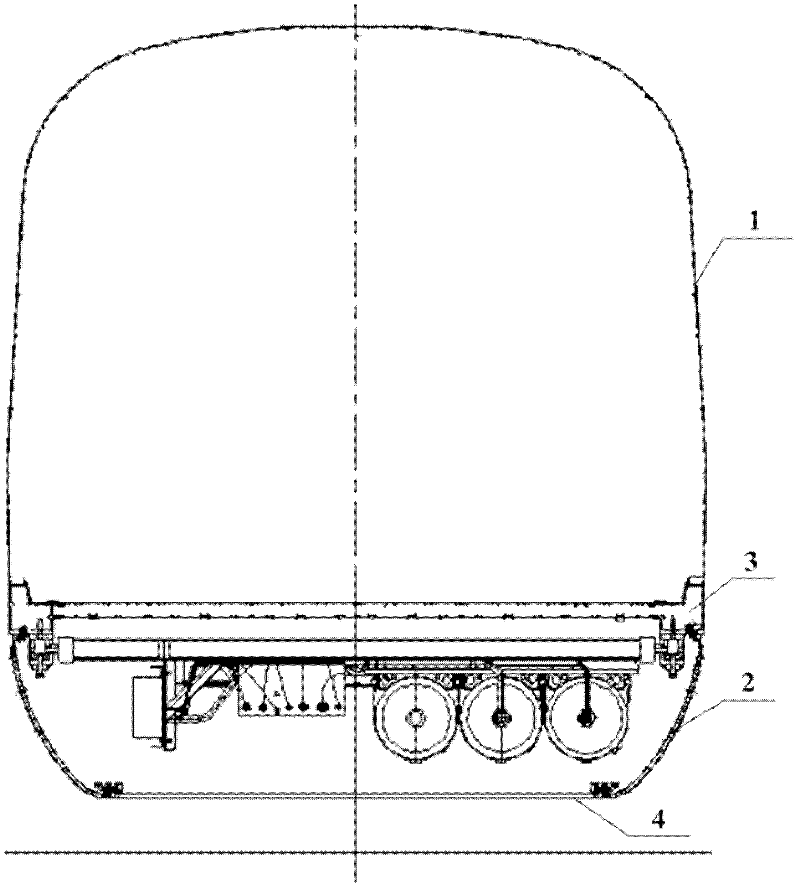

[0049] Embodiment 1 of the present invention provides an apron locking failure protection device, which is used to be installed between the apron and the underframe of the vehicle, and can also be installed on equipment with similar requirements.

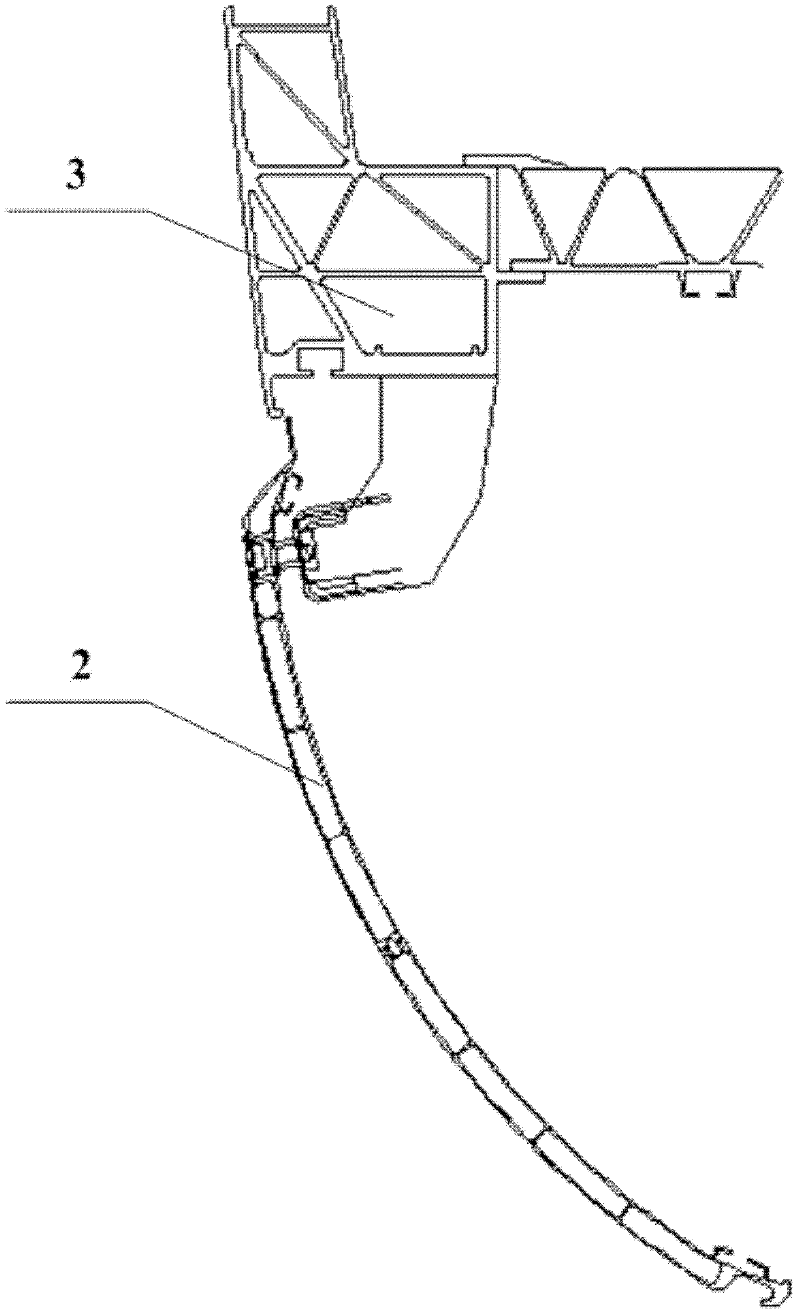

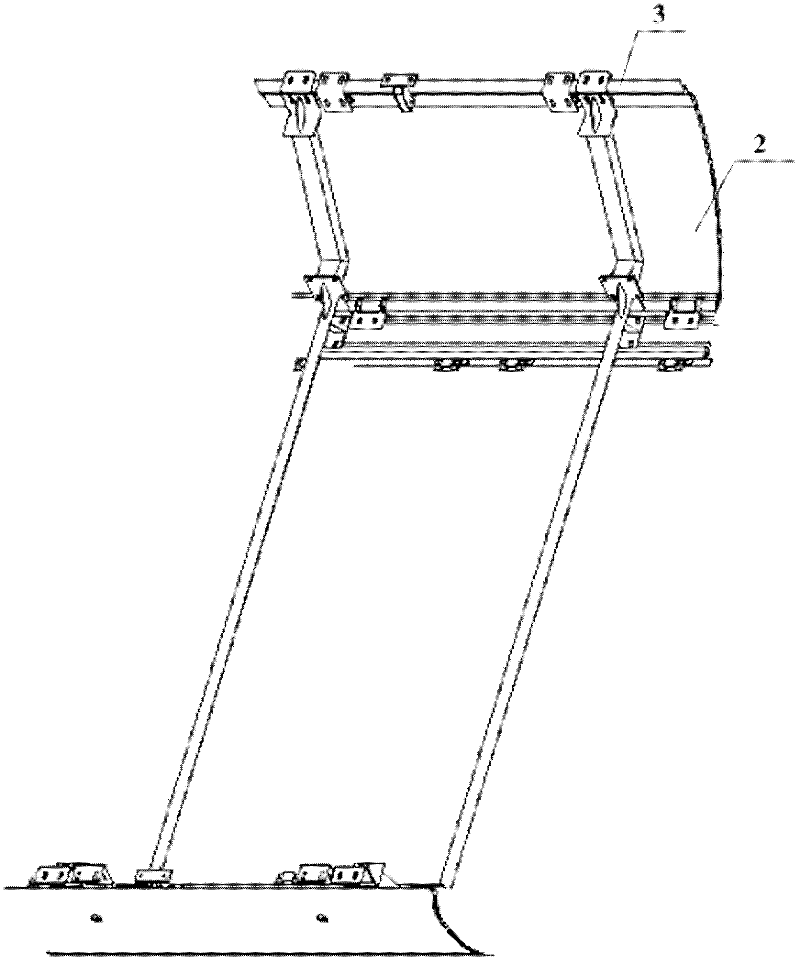

[0050] see Figure 2a , Figure 2b and Figure 2c , the apron locking fail-safe device provided by Embodiment 1 of the present invention includes a first fixing part 7 and a second fixing part 8, the first fixing part 7 is used to be fixedly connected with the vehicle chassis, and the first fixing part 7 is The first hooking part is provided; the second fixing part 8 is used for fixed connection with the upper end of the skirt board, the second fixing part 8 is provided with the second hooking part, and the first hooking part and the second hooking part are arranged correspondingly, And can be hooked and fixed.

[0051] There are many ways to realize the first hook and the second hook, such as crotch and hook hook fixation, crotc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com