Container with nuts with opposite internal and external threads

A technology of internal and external teeth and nuts, which is applied in the field of packaging boxes for goods, can solve problems such as troublesome, time-consuming disassembly of packaging turnover boxes, deformation, etc., and achieve the effect of fixing firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

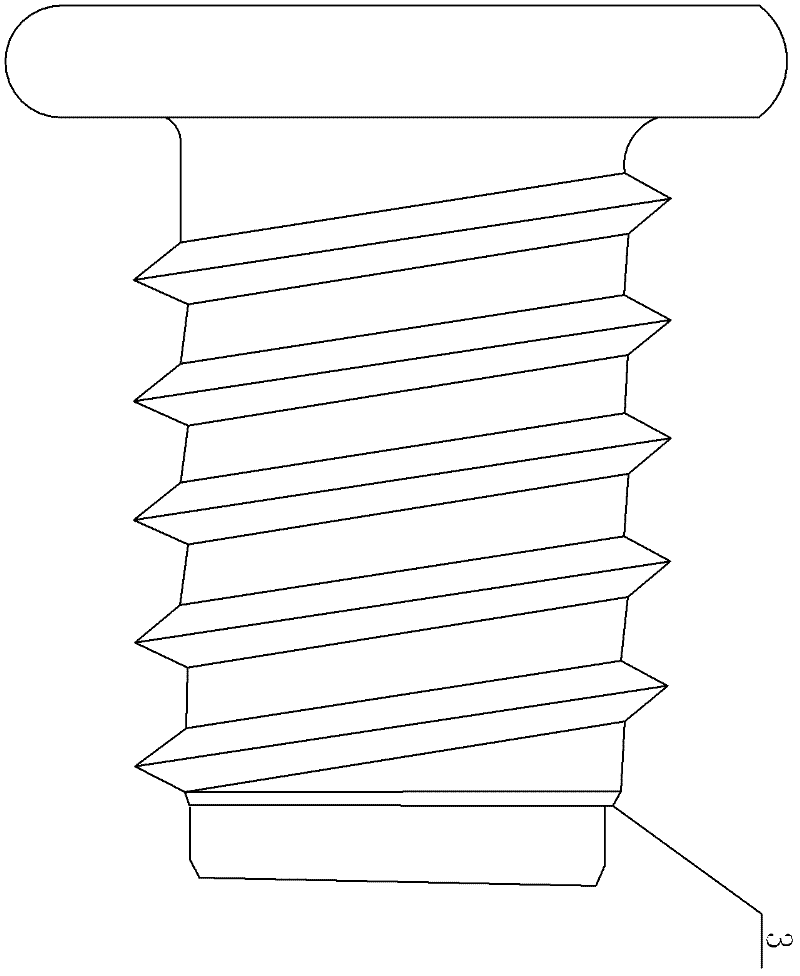

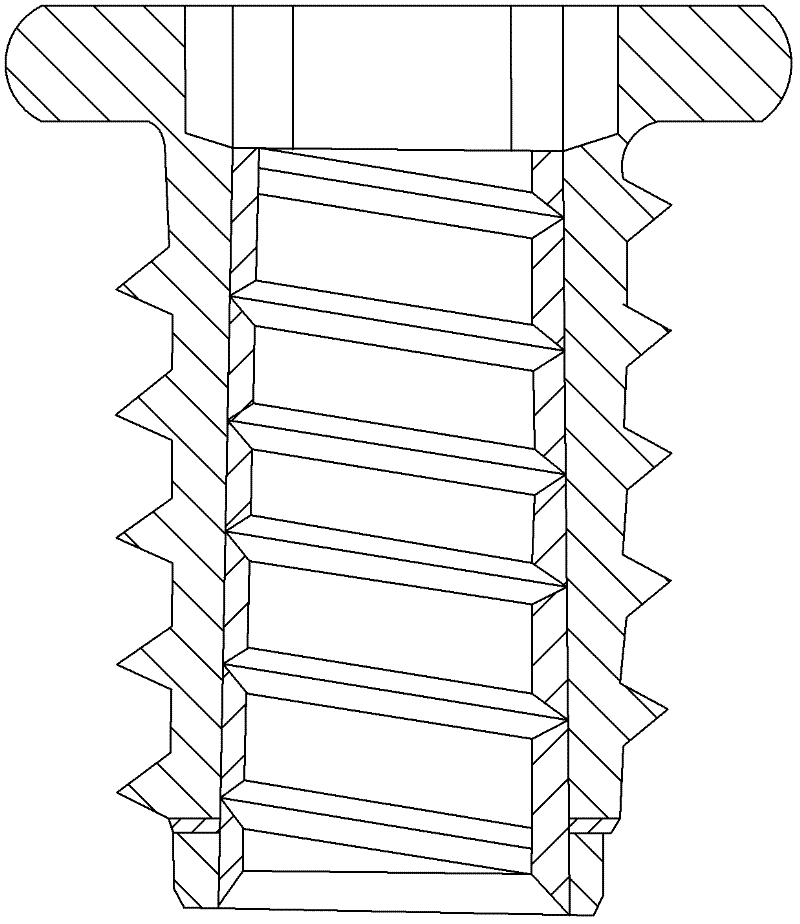

[0012] Such as Figure 5 As shown, a packaging turnover box is composed of six box panels such as a bottom panel, four surrounding side panels, and an upper cover panel. There are four arranged wooden shoulders under the bottom plate, and the wooden shoulders on both sides are located under the left and right ends of the bottom plate. Four side panels are erected around the top of the bottom panel, and the side panels are covered with cover panels. Such six multi-layer glued wooden box boards and four wooden poles form the box body. Adjacent wooden box boards are perpendicular to each other and the edge of one wooden box board overlaps with the end surface of the other wooden box board; The end faces of a box board coincide with each other. After matching each box board, cover each corner of the box with fixed angle connectors, wherein the eight corners of the box are fixed with fixed angle connectors 2, and the fixed angle connectors are three interconnected And the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com