Screw type precisely-lifting adjustment supporting device

A support device and screw-type technology, applied in the direction of the lifting device, etc., to achieve the effect of ensuring position accuracy, reliable positioning, and reducing tilt errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

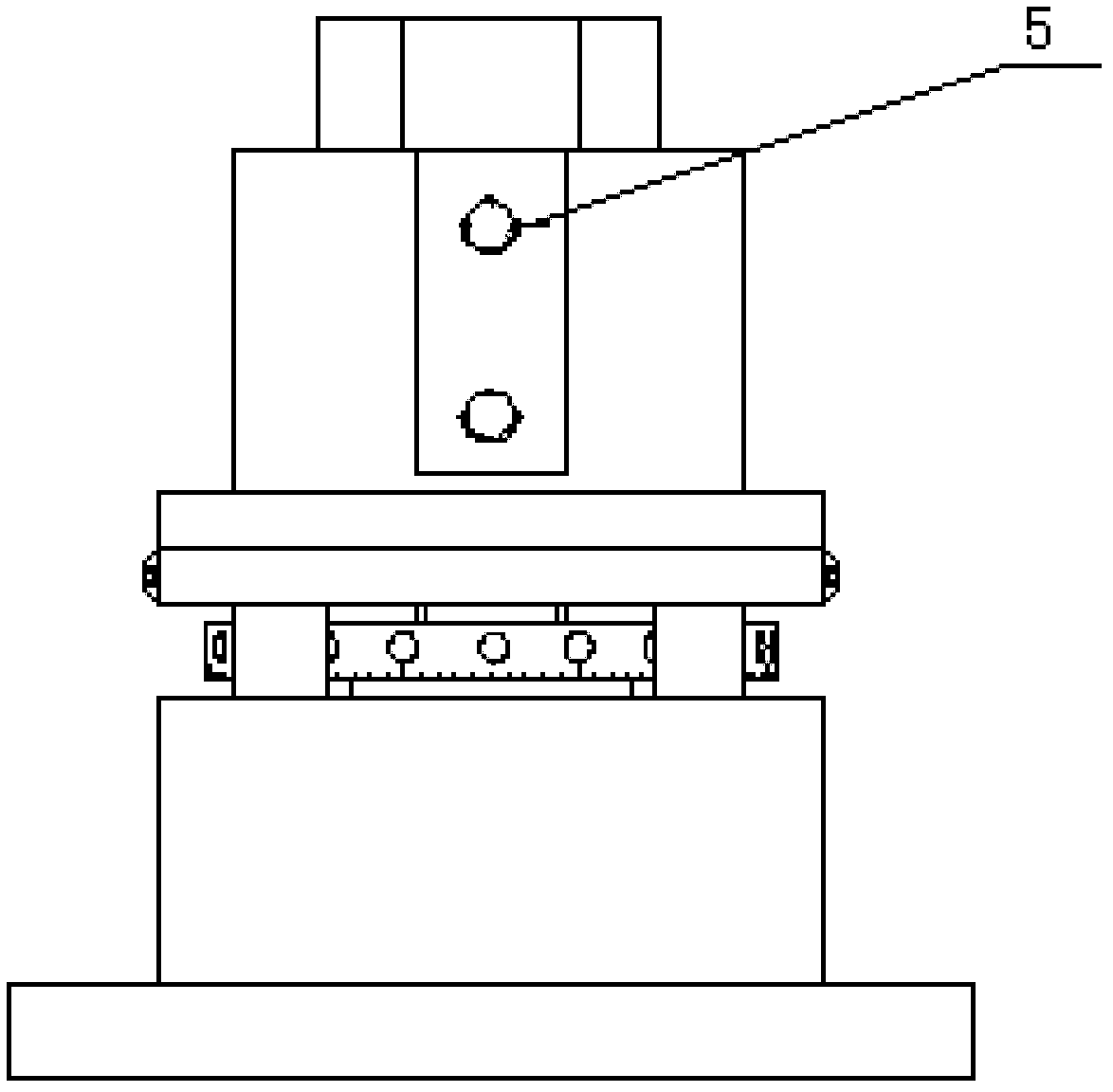

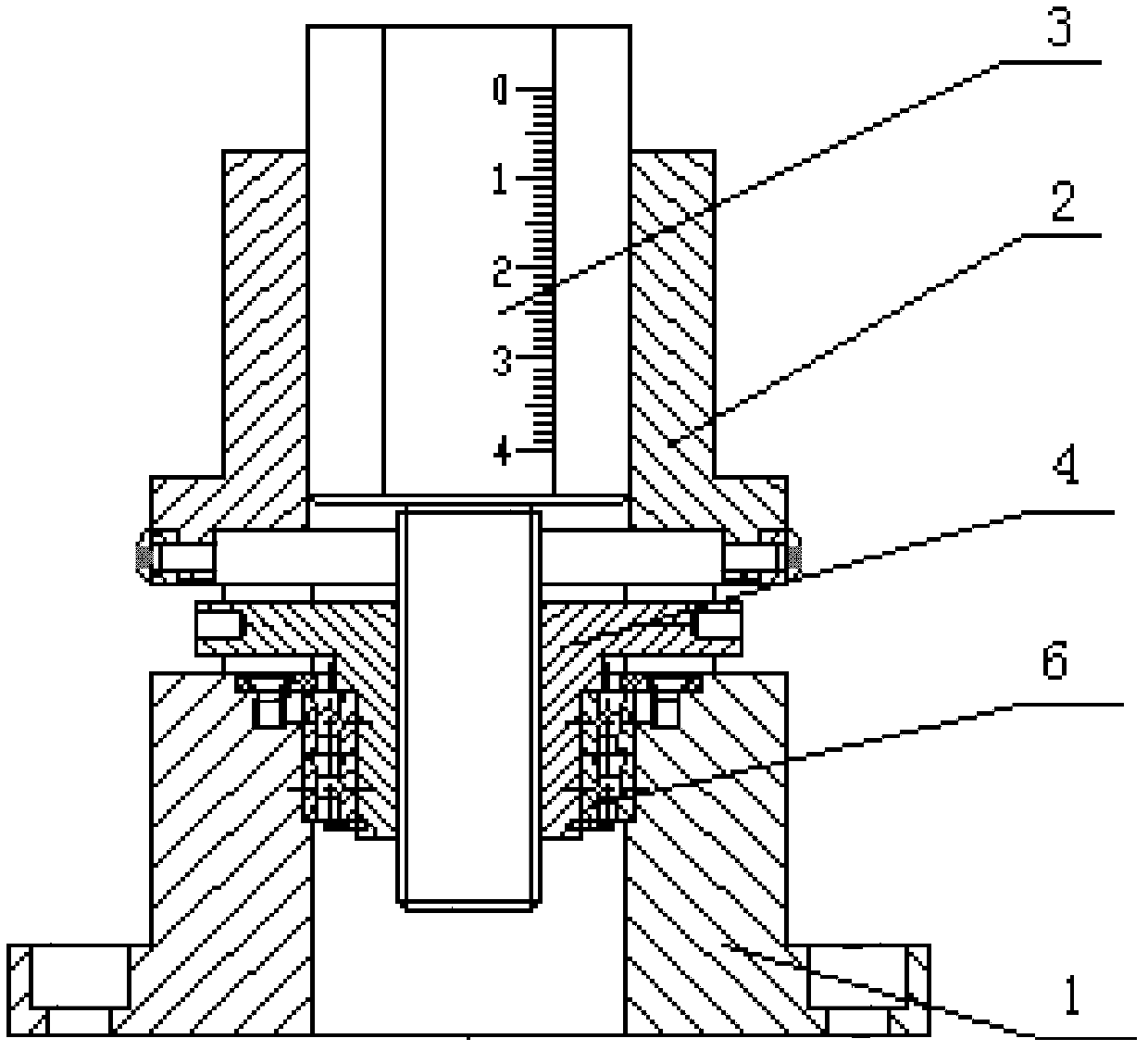

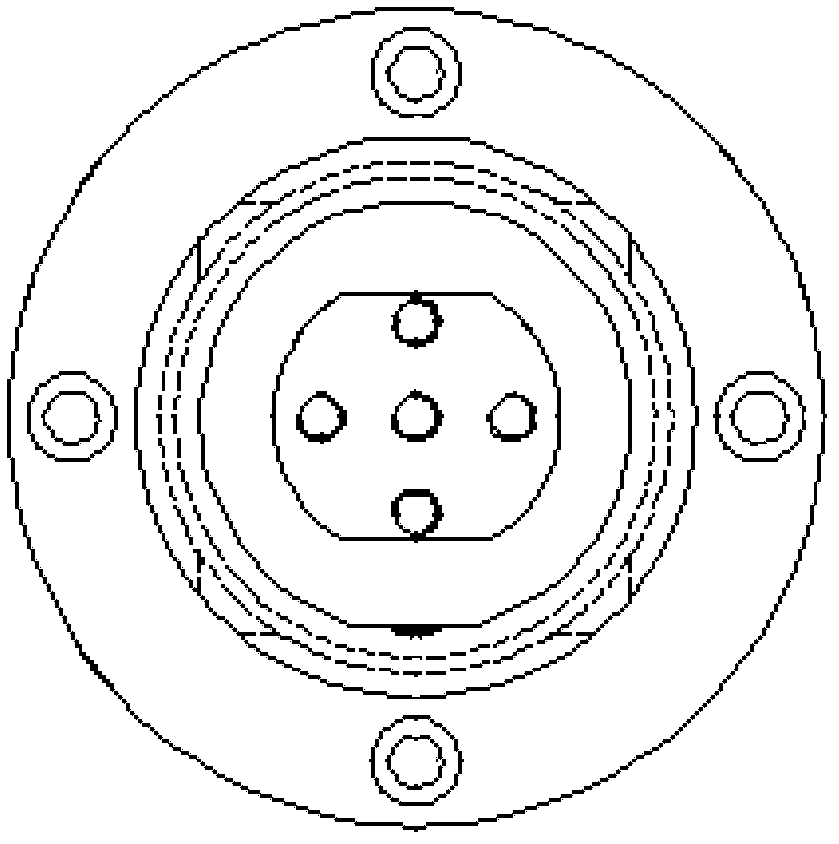

[0021] Such as Figure 1~3 As shown, a screw-type precision lifting adjustment support device is mainly composed of a main base 1, a cage 2, a lifting platform 3, an adjustment disc 4, a locking screw 5 and a holding bearing 6.

[0022] The base and the base of the main base 1 of the device are hollow cylindrical, the base is located above the base and the cross-sectional area is smaller than the cross-sectional area of the base to keep the device placed stably, and there are two heights above the base. Consistent bosses, a horizontal crossbar is arranged above the bosses, and the base, body, boss and crossbar are an integrated structure; the bottom and body of the cage 2 are hollow cylindrical integrated structures, The frame body is located above the bottom of the frame and has a cross-sectional area smaller than the bottom of the frame. The cross-sectional area of the hollow part of the main base 1 and the cage 2 is the same; For reference during rough adjustment, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com