Core/sheath glass with good compatibility for rigid optical fiber

A compatible, core glass technology, applied in the field of optical fibers, which can solve the problems of decreasing the numerical aperture of optical fibers, reducing the contrast and image quality of transmitted images, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

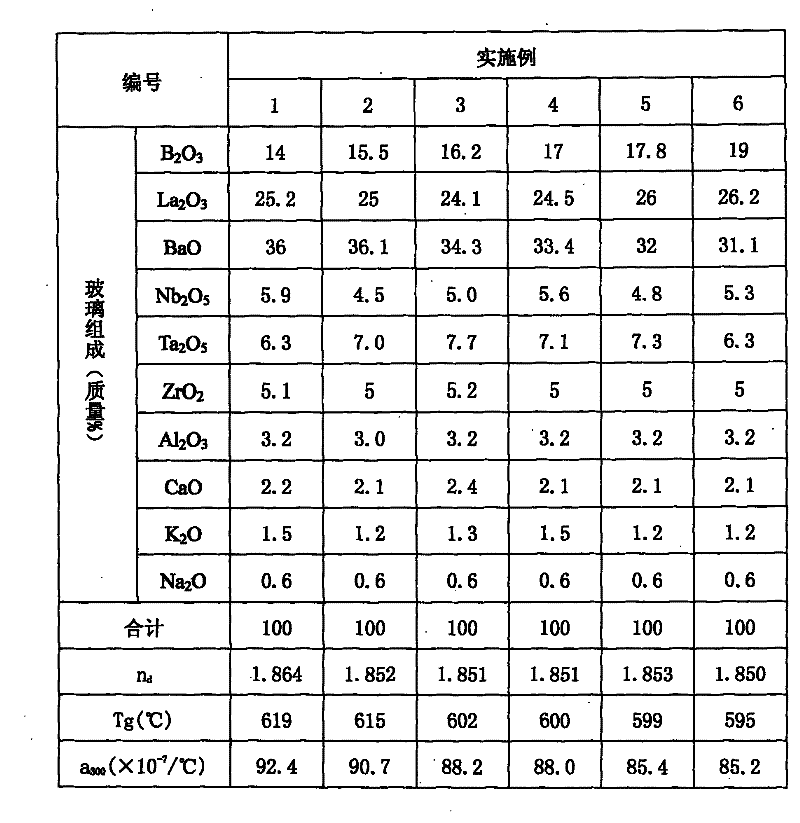

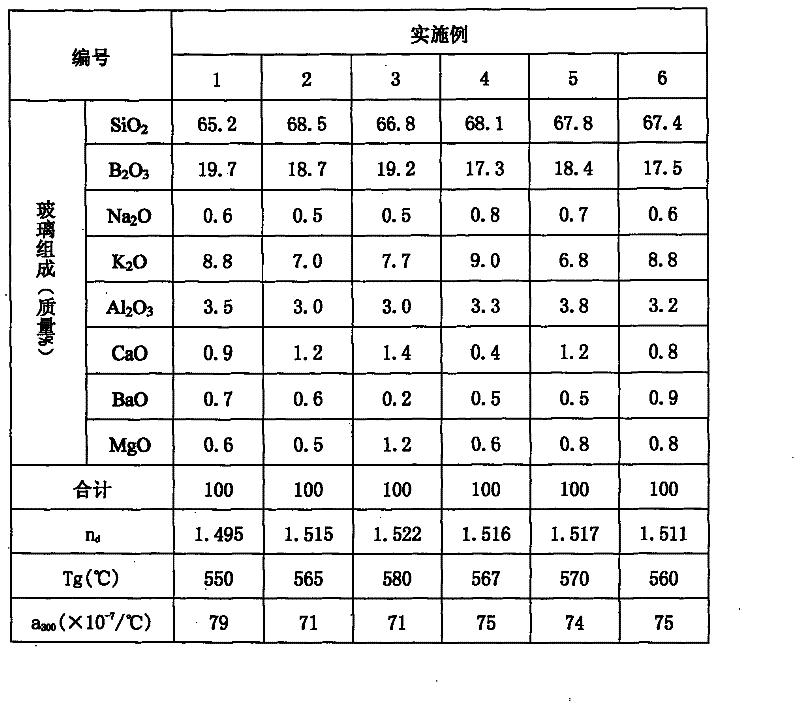

Examples

specific Embodiment approach

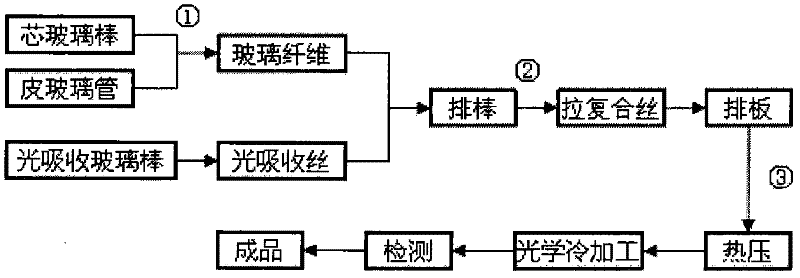

[0020] Below in conjunction with accompanying drawing and specific embodiment, the utility model is described in further detail.

[0021] Such as figure 1 As shown, the core and skin glass for hard optical fiber are formed by heat fusion of core glass skin glass and light-absorbing glass. Among them, ①②③ need to be heated to the softening temperature of the glass at high temperature. If the chemical compatibility of the core and skin glass is poor and the glass components penetrate each other, the refractive index at the interface between the core and the skin will change, which will affect the total reflection at the interface and reduce the The light-gathering ability of rigid optical fibers.

[0022] In addition, in order to meet the requirements of the process, the thermal properties of the three glass materials must also match each other. It is required that the softening point of the core glass is higher than that of the skin glass (about 30-100 ° C), so that the skin w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap