Cylinder head of small general gasoline engine and its gasoline engine

A general-purpose gasoline engine and cylinder head technology, applied in the direction of cylinder, cylinder head, machine/engine, etc., can solve the problems of not achieving economical or rational use, not improving the combustion efficiency of the engine, increasing the use cost and maintenance cost, and eliminating the dead angle. The effect of reducing carbon deposits, improving intake and exhaust efficiency, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

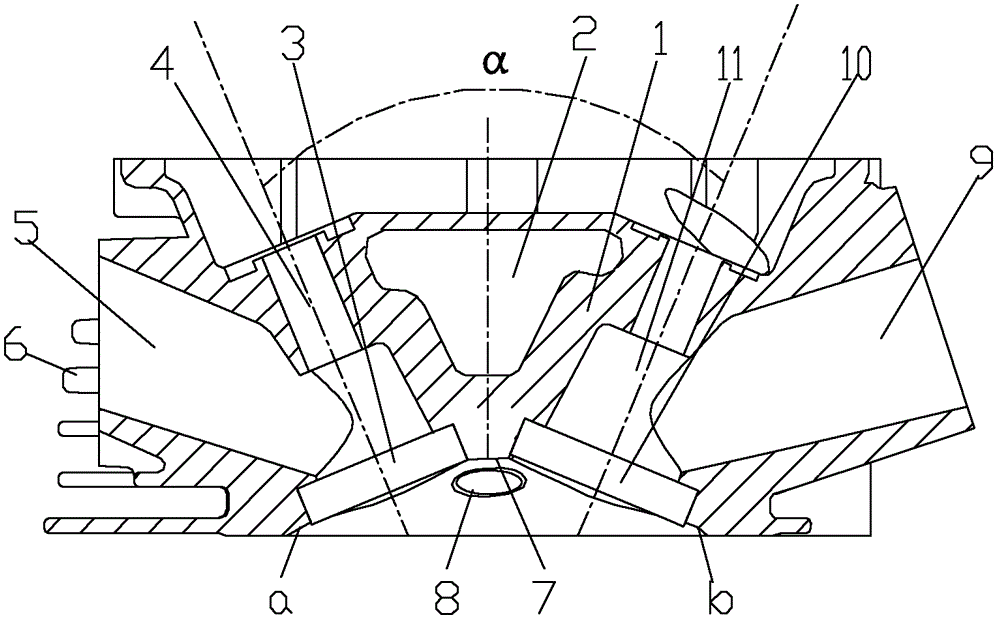

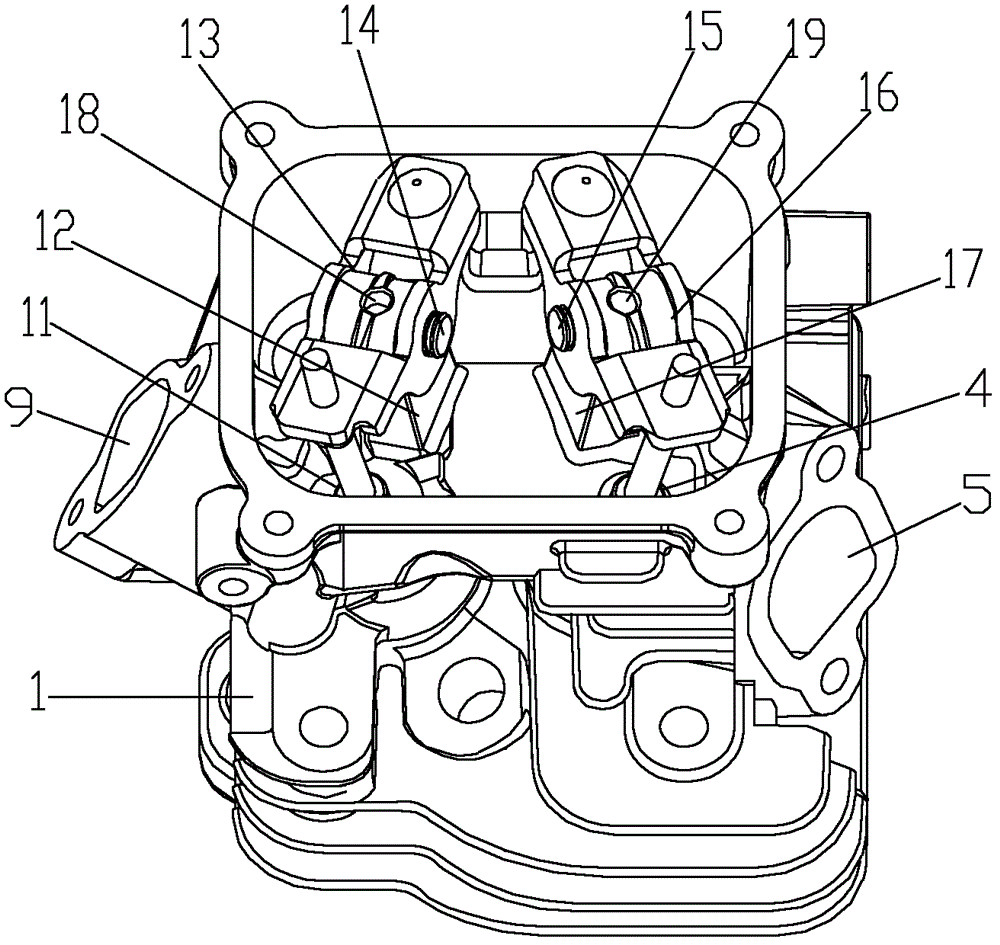

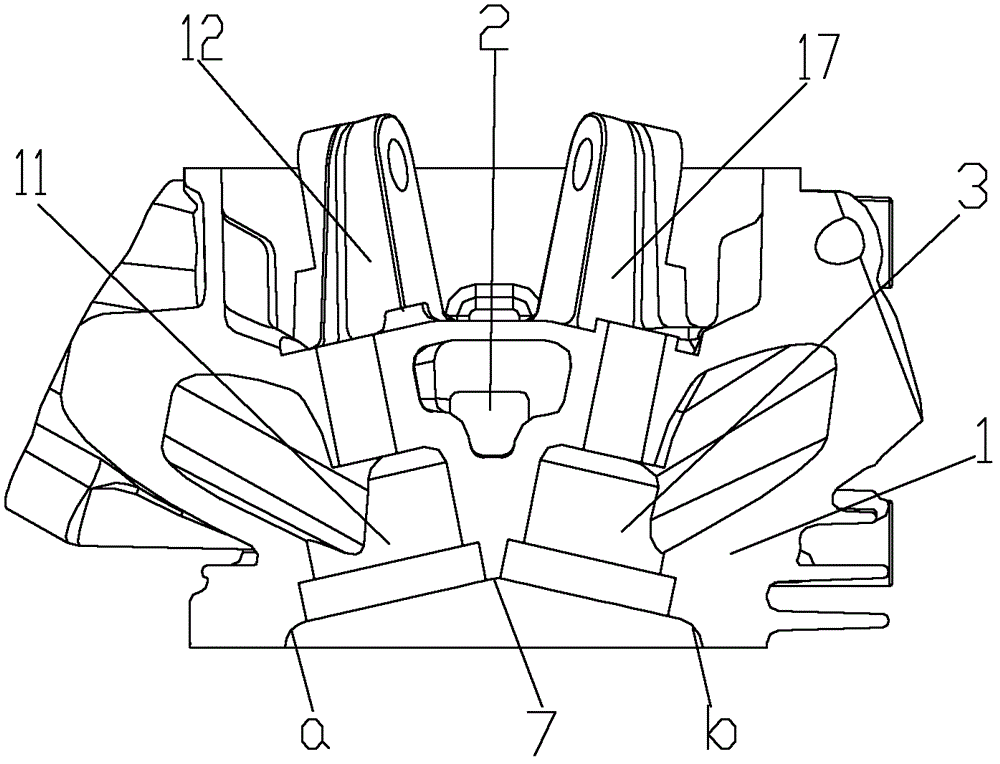

[0026] figure 1 It is a schematic diagram of the cylinder head combustion chamber and valve arrangement structure of the present invention, figure 2 It is a schematic diagram of the arrangement structure of the cylinder head rocker arm of the present invention, image 3 It is a schematic diagram of the arrangement structure of the rocker seat of the present invention, Figure 4 is the cross-sectional view of the cooperation between the rocker shaft and the rocker seat, Figure 5 It is a schematic diagram of the combustion chamber surface of the cylinder head, as shown in the figure: the small general-purpose gasoline engine cylinder head of the present embodiment includes a cylinder head body 1 and an intake passage 9, an exhaust passage 5 and a spark plug installation hole 8 arranged on the cylinder head body 1 The combustion chamber surface 7 is formed inside the cylinder head body, and the combustion chamber surface 7 is an arched smooth curved surface. The arched smooth c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com