Vehicular audio encoder

A car audio and encoder technology, applied in the encoder field, can solve problems such as driving bumps, large frictional resistance, and torque drop, and achieve smooth and stable torque changes, prolong service life, and relieve excessive pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

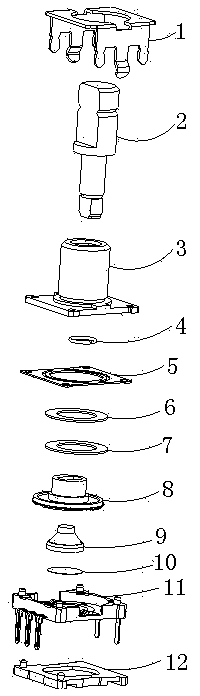

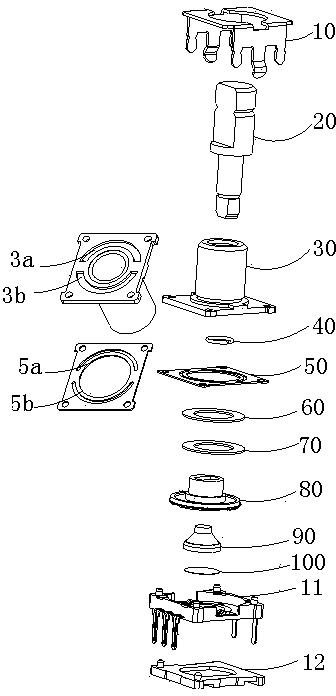

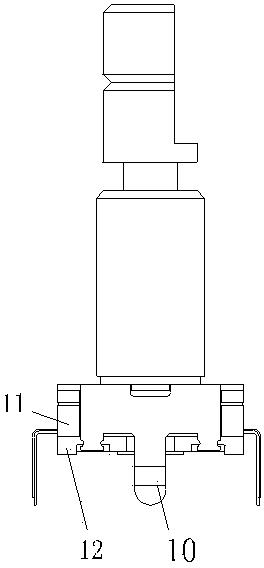

[0013] Such as Figure 2~4 As shown, the car audio encoder disclosed by the present invention includes a base and an upper cover 10, and a rotary encoding assembly and a pressing assembly installed in the base. The base includes a needle base 11 and a bottom plate 12 installed below the needle base. The base 11 has an inner cavity, and the rotary encoding component and the pressing component are installed in the inner cavity of the needle base 11 .

[0014] Wherein, the rotary encoding assembly includes a rotating shaft 20 , a shaft sleeve 30 , a snap ring 40 , a spring washer 50 , an elastic buffer plate 60 , a friction plate 70 , and a rotor 80 . The spring washer 50 is installed on the base, and the shaft sleeve is also installed on the base, and the lower end presses the spring washer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com