Heat exchange system and heat exchange method

A technology of heat exchange system and heat exchange module, which is applied in the field of battery heat exchange, can solve the problems of low energy utilization rate and high energy consumption of power supply system, and achieve the effect of ensuring good operation and solving high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

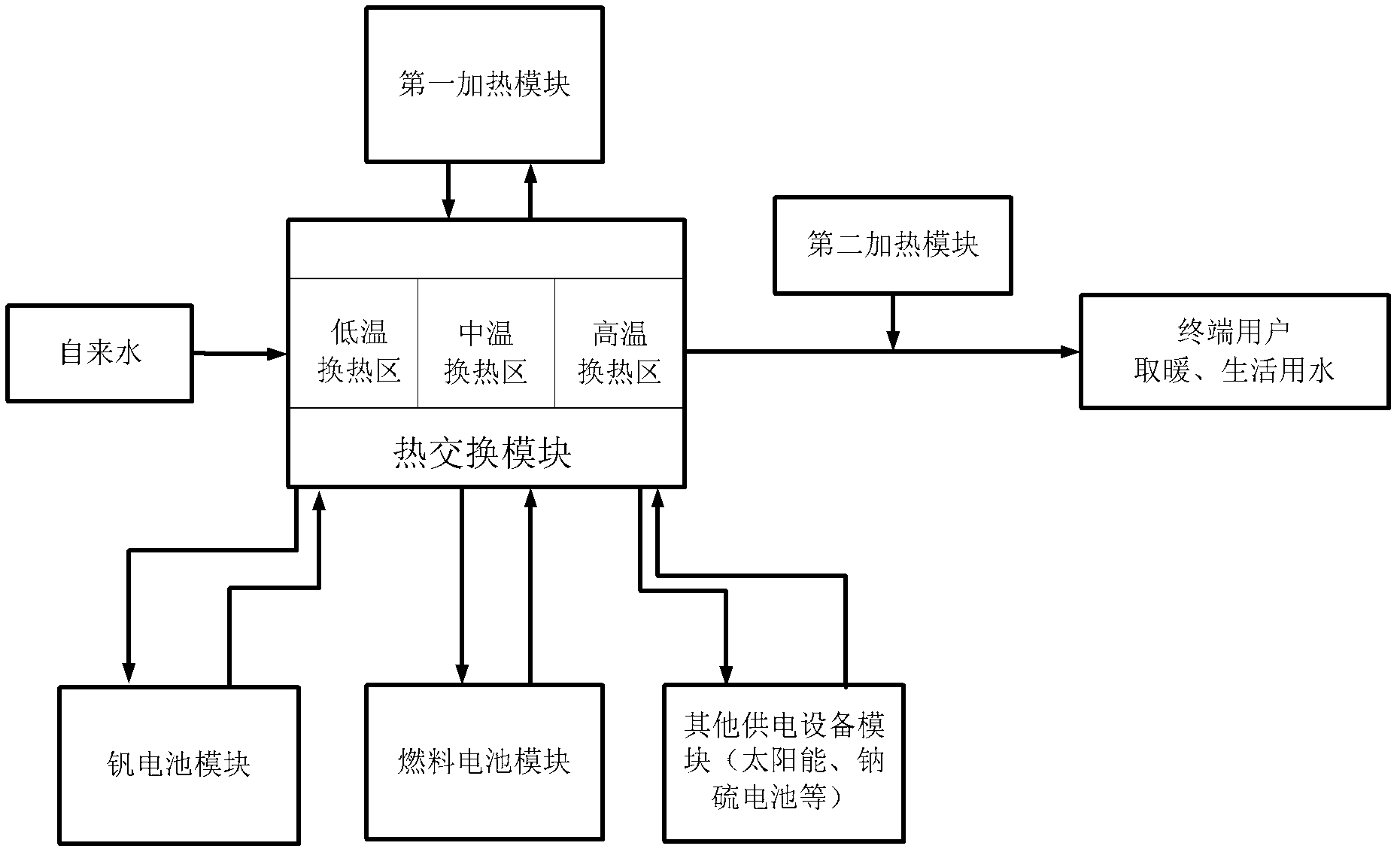

[0032] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

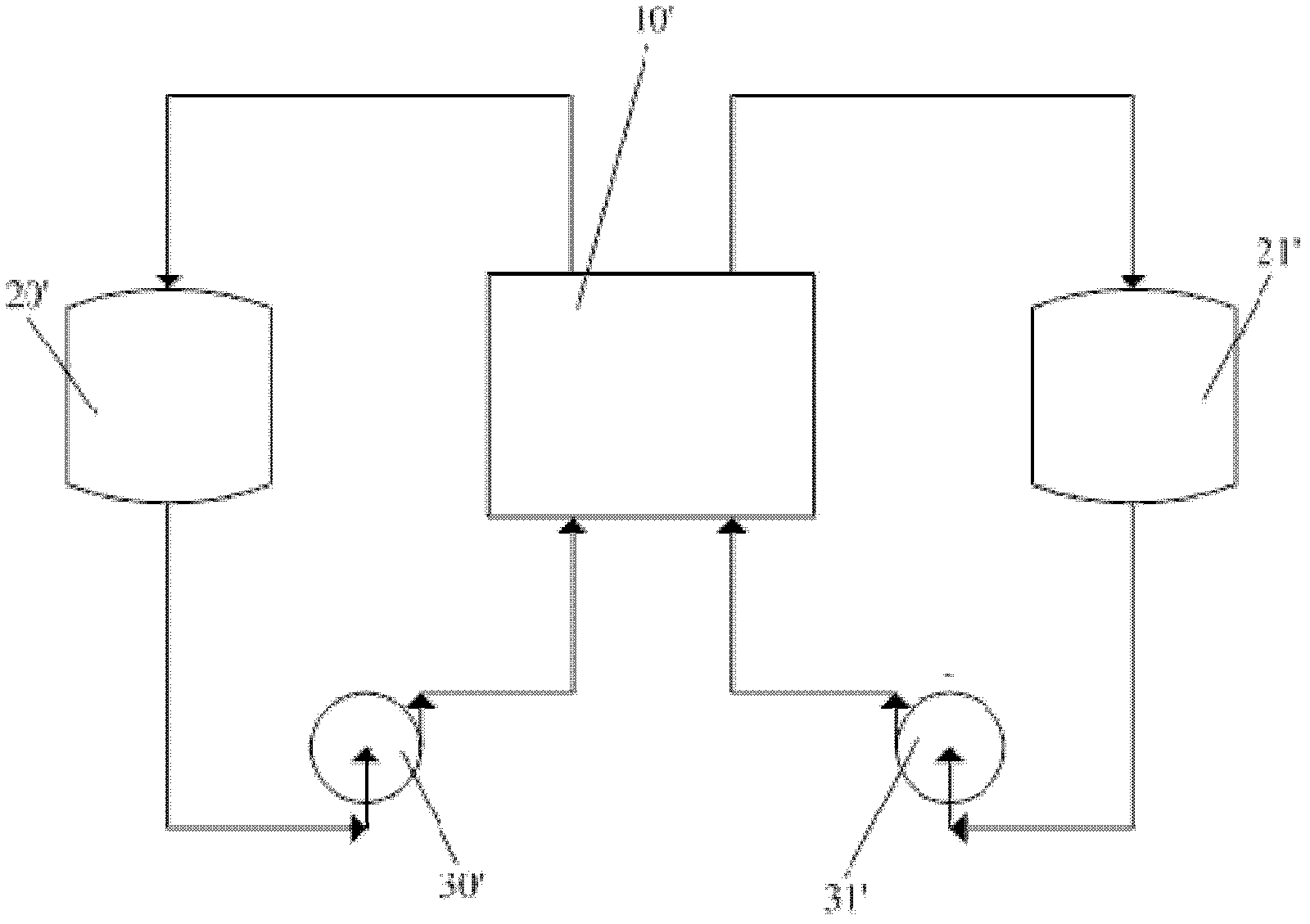

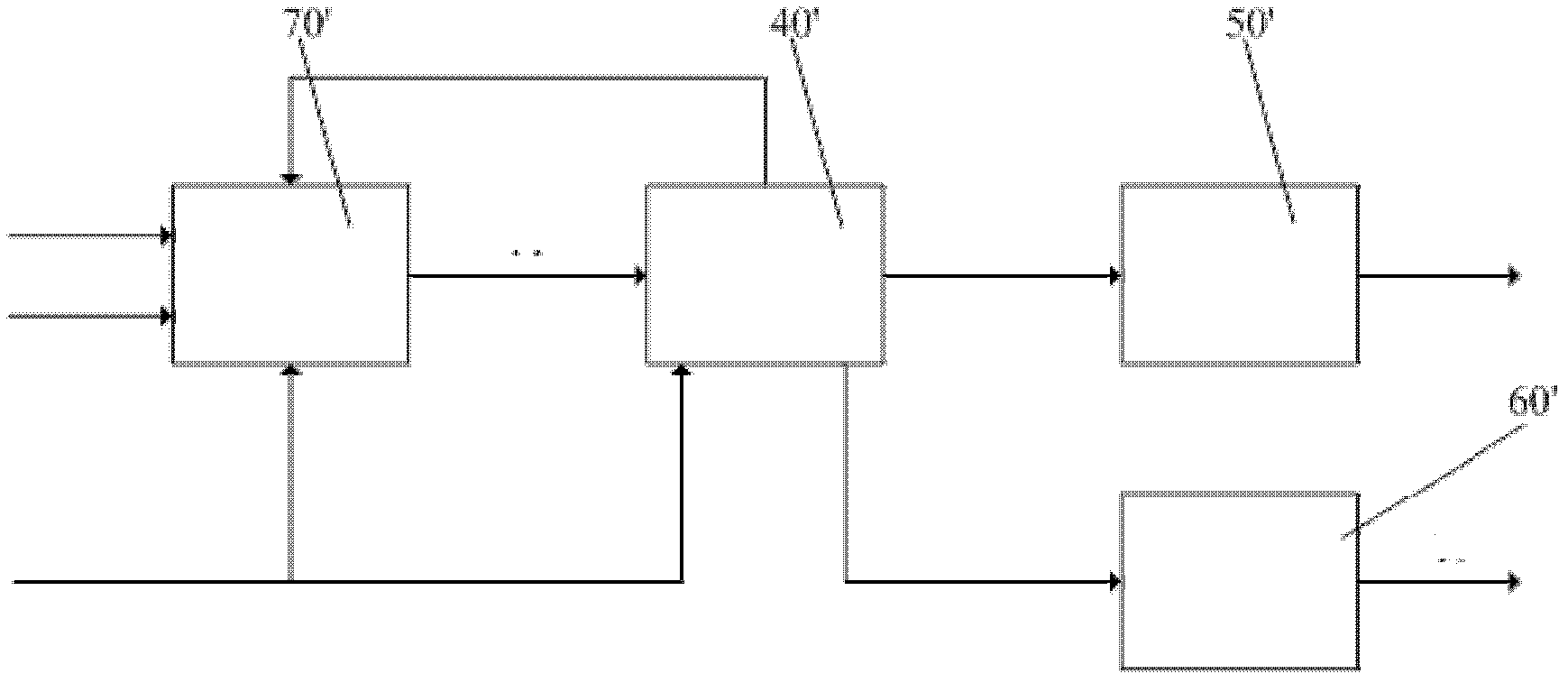

[0033] The heat exchange system provided by the present invention includes a power supply sub-system and a heat exchange sub-system, and the battery modules of the power supply sub-system include a vanadium battery module, a fuel cell module and other power supply modules (such as solar energy, sodium-sulfur battery) and the like. In order to clearly describe the embodiment of the present invention, the flow battery system and the fuel cell system in the prior art are firstly introduced. figure 1 A schematic diagram showing a flow battery system in the prior art, such as figure 1 As shown, the liquid flow battery system includes a battery stack 10', a positive electrode electrolyte liquid stor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap