Dust cleaner of forage hay cutter

A grass cutting machine and fodder technology, which is applied in the direction of cutting equipment, agricultural machinery and implements, applications, etc., and can solve problems affecting the quality of forage grass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

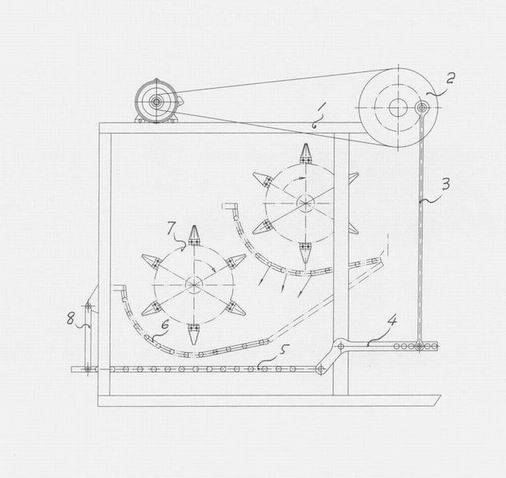

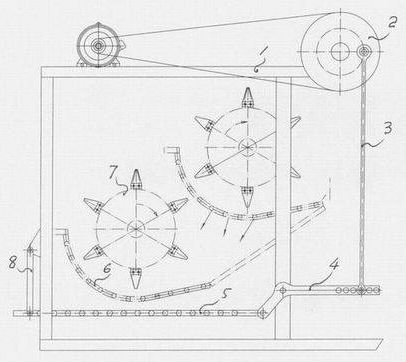

[0005] The present invention is described in detail in conjunction with the following examples, the dust contained in the forage grass processed by the existing grass cutting machine is relatively high, and the reason is that the forage grass is processed by the existing grass cutting machine, because the grass chopped by the grass cutting roller 7 Fall into the feed bin through the sieve plate hole, and the sieve hole of this sieve plate 6 is larger (need to leak the chopped grass), and the finer dust and broken grass fall into the feed bin together. In order to solve the above problems, the present invention adds a sieve plate 5 below the sieve plate 6. The sieve hole of this sieve plate is smaller than the broken grass, so that the broken grass cannot pass through, but the dust can pass through. This sieve plate is used as the left, right and upper , Vibrating down, so that the broken grass and dust vibrate on the sieve plate, the heavier dust and the broken grass are separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com