Three-dimensional (3D) cloth-wrapping tensioning mechanism for seat backrest cloth-wrapping machine

A tensioning mechanism, backpack technology, applied in the production of chairs, other seating furniture, furniture covers, etc., to save manpower, improve product quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

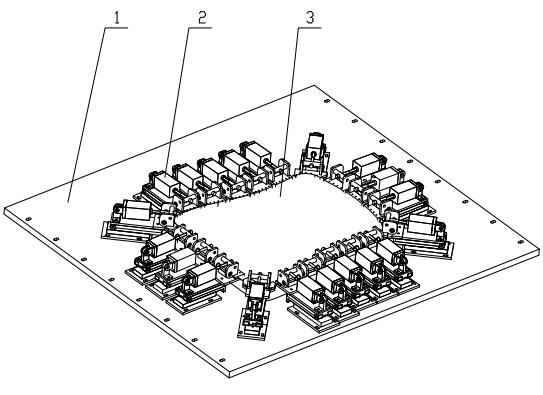

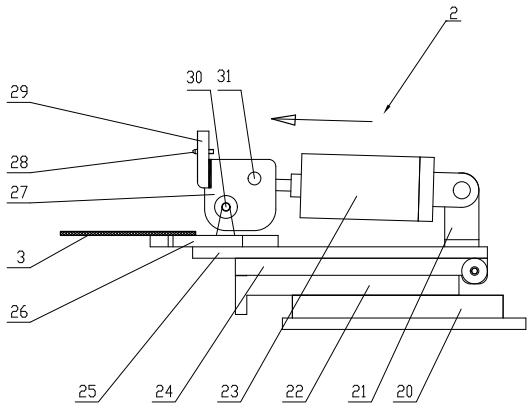

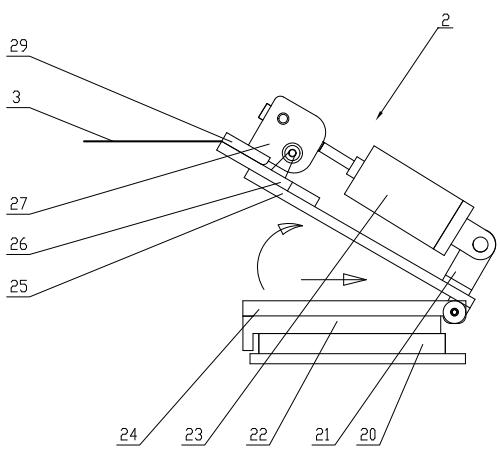

[0021] See figure 1 , figure 2 , the present invention includes a fixed plate 1 with a hole for placing the cloth mechanism in the center, figure 1 The mesh cloth 3 has been placed in the supporting hole of the supporting cloth mechanism described in , and the shape and size of the setting hole should match the supporting cloth mechanism. On the fixed plate 1, the clamping device 2 is fixed around the hole for placing the cloth mechanism. The clamping device 2 includes a pneumatic slide base 20, and the pneumatic slide base 20 is connected to the pneumatic slide table 22. The pneumatic slide table 22 is connected with the pneumatic system. Connection, the pneumatic slide table 22 is connected to the clamping fixed plate 24, and one end of the clamping fixed plate 24 is connected to the cylinder rotating plate 25 by means of a hinge shaft,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com