Air pressure brake type hydraulic coupling hose or cable coiling block

A technology of air pressure braking and cable reel, which is applied in the field of hose or cable reel, which can solve the problems of large anti-pull force, complicated control, and inconvenient adjustment, etc., and achieve stable and accurate air pressure braking, soft mechanical properties, and easy conversion smooth and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

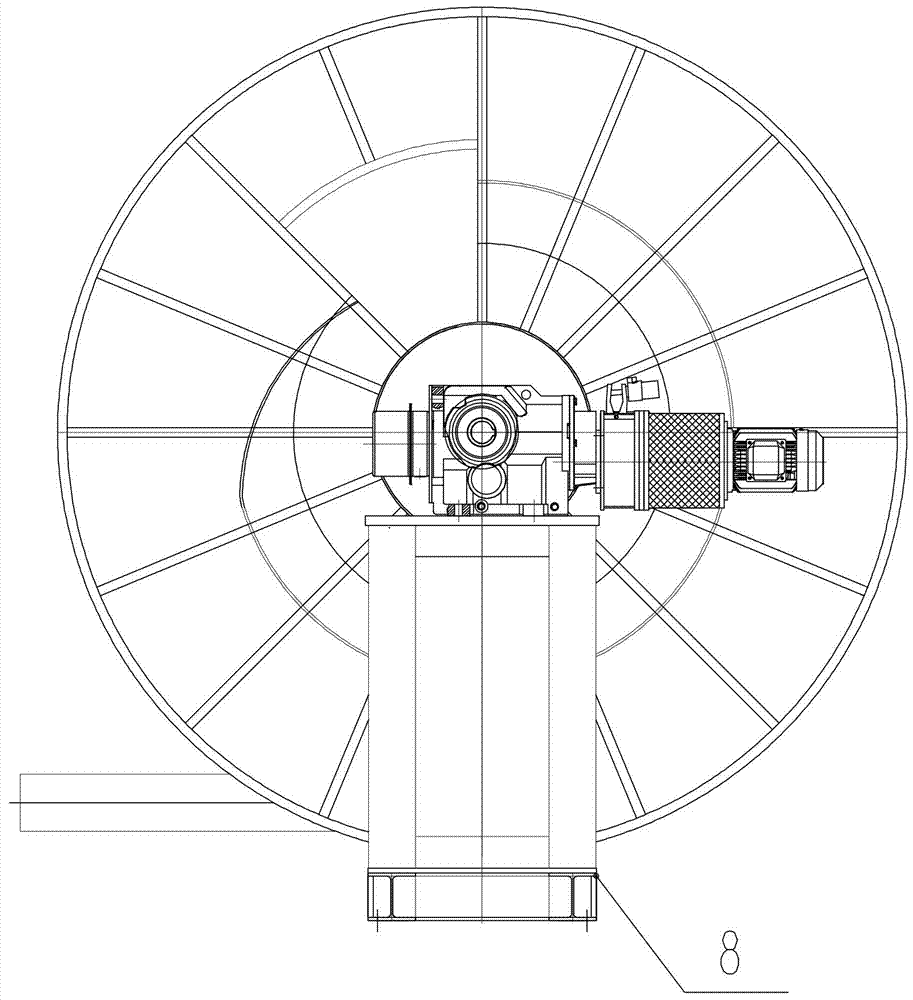

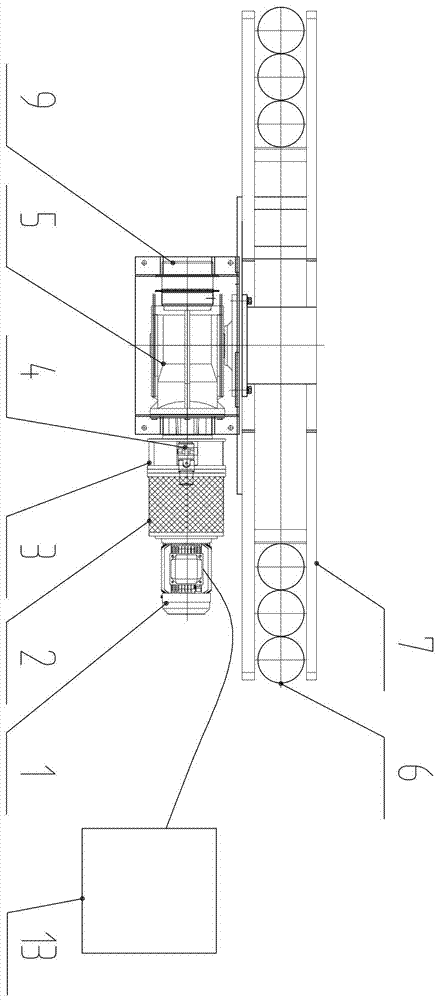

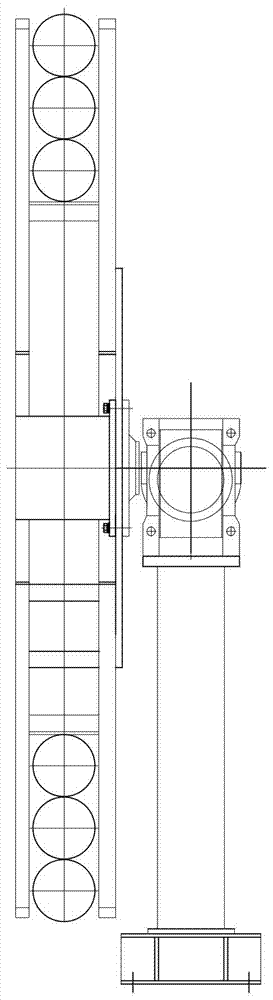

[0021] from Figures 1~3 It can be seen that the present invention is a pneumatic brake hydraulic coupling drive hose or cable reel, including a drive motor 1, a hydraulic coupling 2, a pneumatic brake 3, a connection mount 4, a reduction box 5, a hose or a cable reel 7. Connecting shaft 10 , transition plate 11 , transition plate 12 , electrical control box 13 . The hydraulic coupling 2 is connected to the driving motor 1 through a rigid coupling, and the electric control box 13 controls the forward and reverse rotation of the driving motor 1, thereby driving the hydraulic coupling 2 to rotate. The transition plates 11 and 12 are respectively connected with the driving motor 1 and the reduction box 5 , and the two ends of the connecting shaft 10 are respectively connected with the output shaft of the driving motor 1 and the main shaft of the reduction box 2 . In the present invention, an installation support 8 can be added under the base of the reduction box 5, and the struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com