Clamp

A fixture and fixture seat technology, applied in the directions of clamping, manufacturing tools, support, etc., can solve the problems of complicated clamping and alignment, poor shock resistance of the fixture, complex fixture structure, etc., and achieves simple and convenient installation and low cost. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

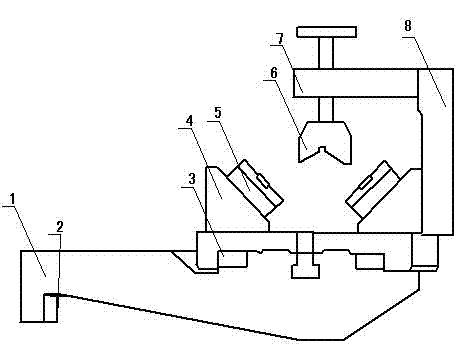

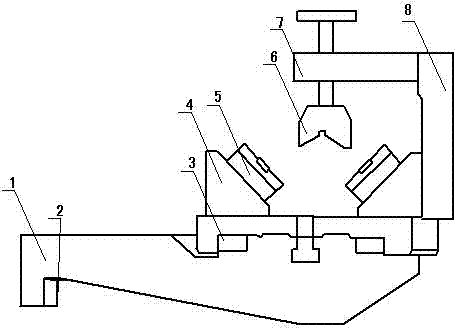

[0012] Such as figure 1 As shown, the present invention includes a fixture seat 1, and pads 2 are movably connected below the fixture seat 1. The lower plane of the fixture seat 1 has two slopes in a V-shaped distribution, and the upper plane has oblique holes and inverted T-shaped grooves. The large fixture block 4 The left and right pads 3 are installed on the fixture seat 1, and the small pads 5 are installed on the two V-shaped surfaces of the large clamp block 4. The large and small clamp blocks 4 and 6 are both V-shaped openings and symmetrically distributed towards each other. The support block 8 is installed on the side of the large clamp block 4, the fixed block 7 is installed on the support block 8, and the small clamp block 6 is screwed on the fixed block 7. The angles and sizes of the two slopes of the fixture seat 1 are consisten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com