Carton handle automatic installation machine

An automatic installation, carton handle technology, applied in packaging, papermaking, transportation and packaging, etc., can solve the problems of worker's finger injury, labor and time-consuming, high cost, save labor, avoid difficult management, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

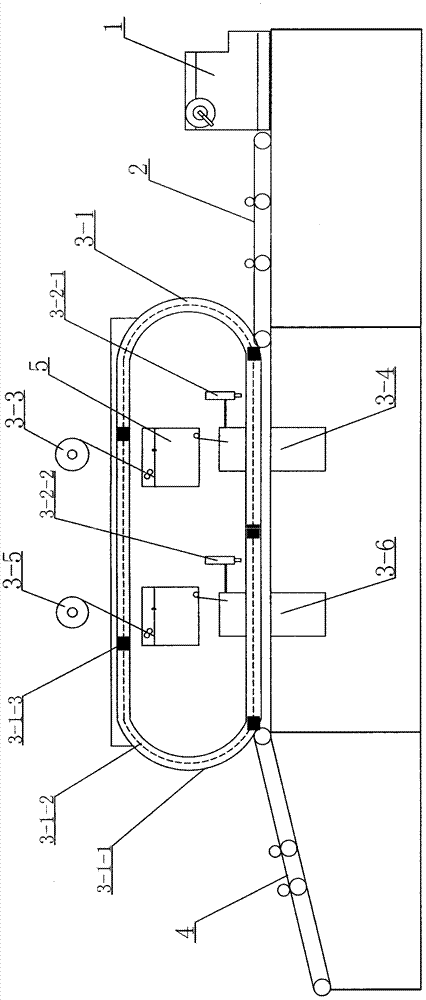

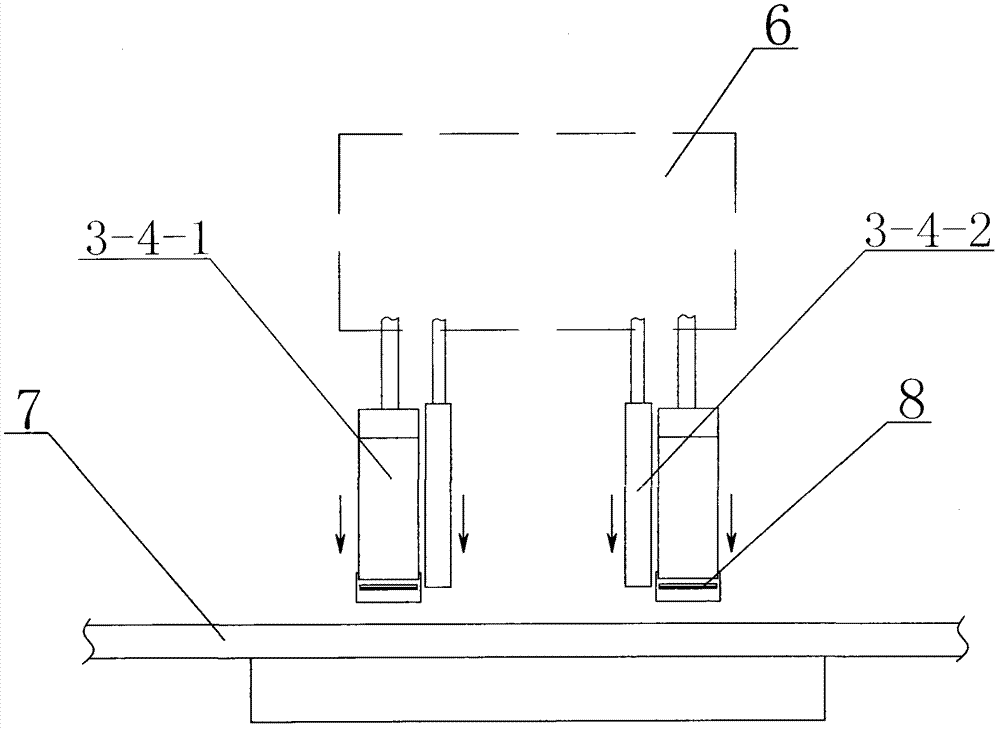

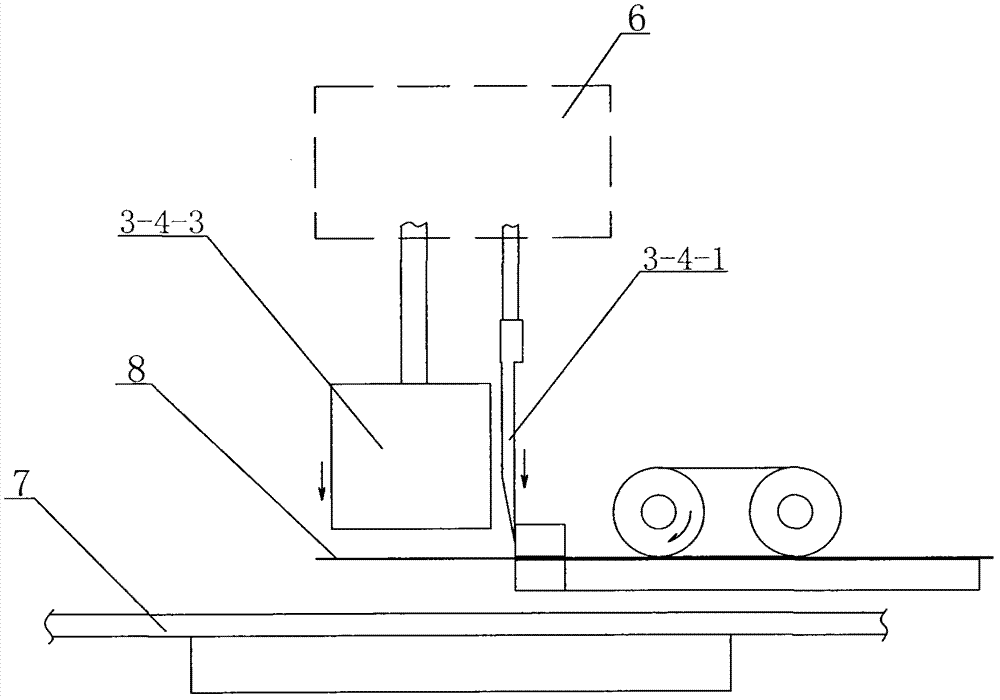

[0029] A carton handle automatic installation machine, such as figure 1 As shown, it includes a carton plate loading and feeding device 1, a conveying part 2, an installation part, a material unloading part 4, and a main console connected in sequence, wherein the installation part is mainly composed of a circular positioning conveying mechanism 3-1, Pre-spraying mechanism, reinforced belt feeding mechanism 3-3, reinforcing belt installation mechanism 3-4, handle belt feeding mechanism 3-5, handle belt installation mechanism 3-6;

[0030] The carton board loading and feeding device 1 mainly includes a finite height outlet and a loading push belt driven by a stepping motor;

[0031] Both the conveying part 2 and the unloading part 4 are mainly composed of driving rollers, conveyor belts and positioning pinches;

[0032] Circular positioning conveying mechanism 3-1 comprises underframe, rotary frame 3-1-1, is provided with a pair of parallel, rotary chain belts 3-1-2 driven by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com