Assembly machine for disposable plastic transfusion bottle

An infusion bottle and disposable technology, which is applied in the field of disposable plastic infusion bottle assembly machines, can solve the problems of inability to assemble plastic infusion bottles, slow assembly speed, and high labor cost, and achieves fast assembly speed, improved efficiency, and labor saving. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

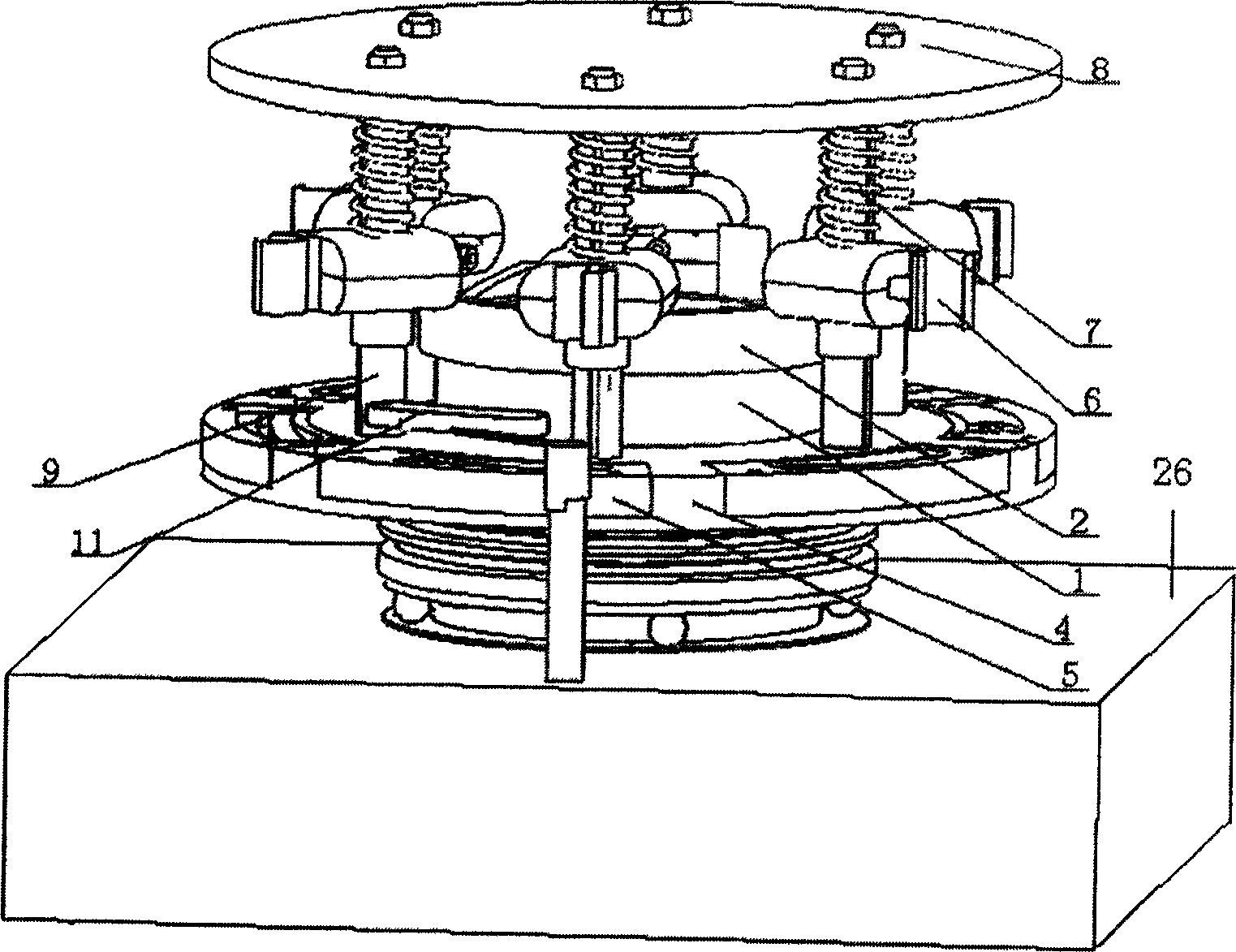

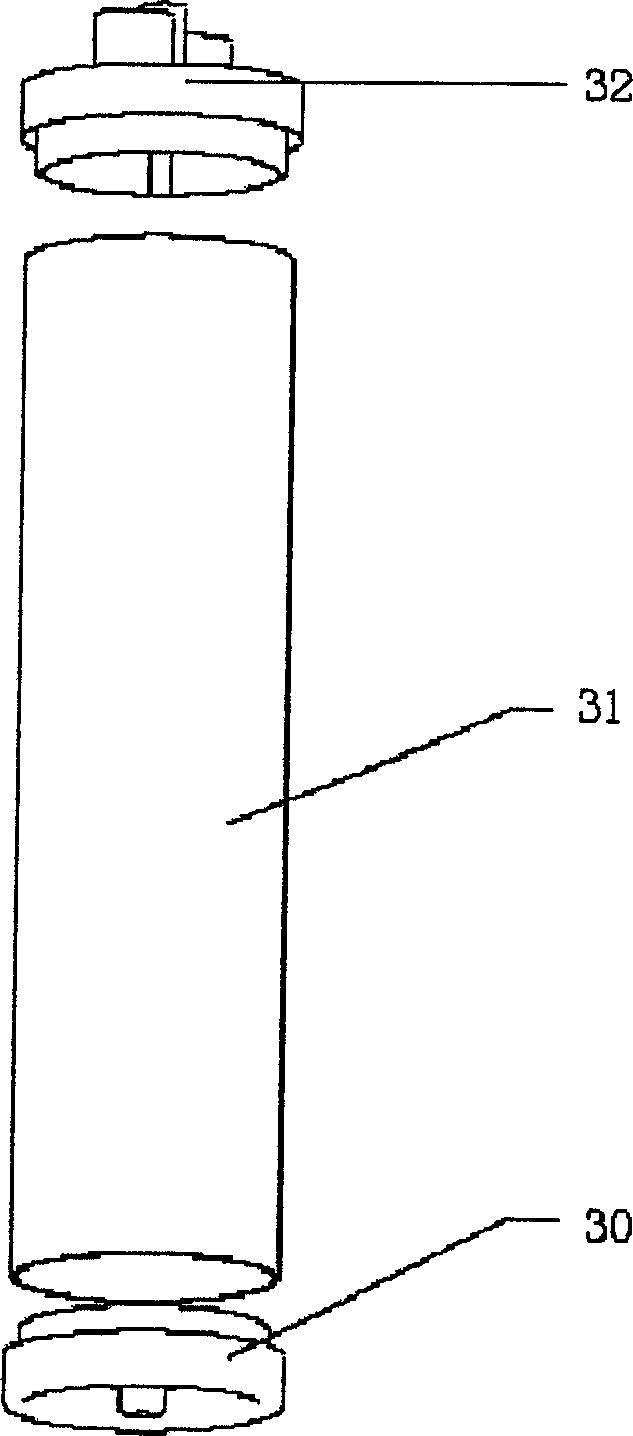

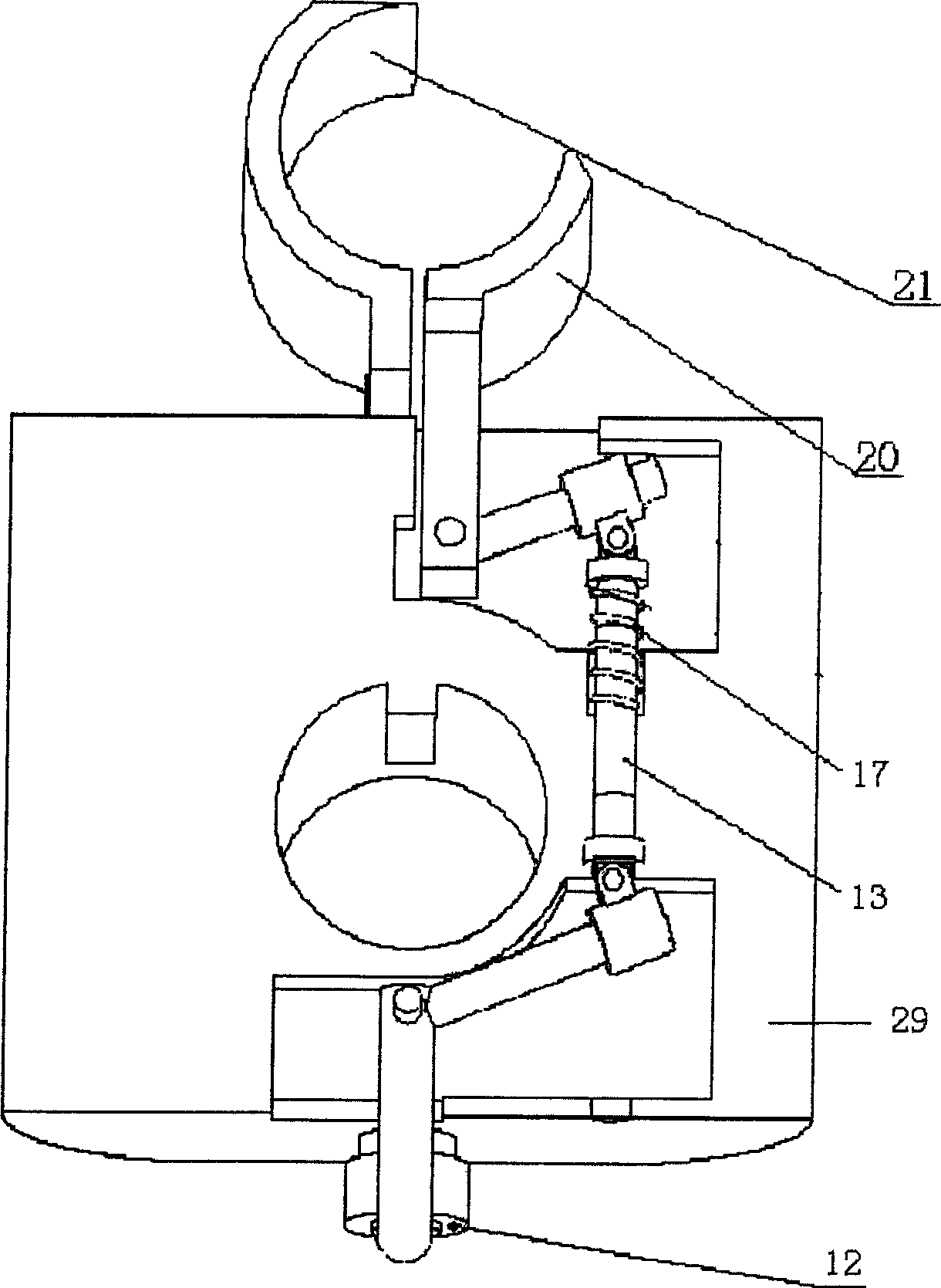

[0019] refer to figure 1 , 2 , 3, 4, 5, a disposable plastic infusion bottle assembly machine, including a frame 26, a turntable 4, a middle platform 1, a ring body 2, the installation table 1 is fixed on the frame 26, and the turntable 4 is sleeved on the installation Outside the platform 1, there is a belt groove under the turntable 4, and the motor drives the turntable 4 to rotate during work. The ring body 2 is set outside the installation platform 1, and the ring body 2 has a first stop piece 3 for pulling the linkage mechanism, a concave part 27 dipped in glue, a concave part 28 for installation, and a concave part 28 for pulling the connecting rod mechanism. The second blocking piece 22 of the rod mechanism, the height of the first and second blocking pieces exceeds the torus 2, and the surface of the first and second blocking pieces facing the toroidal body 2 is a smooth convex arc The surface, of course, can also be a convex surface of other shapes, but the effect i...

Embodiment 2

[0027] The ring body has a first convex surface for pulling the link mechanism, a recess for dipping glue, a recess for installation, and a second convex surface for pulling the link mechanism in sequence. The first convex surface corresponds to the feeding position, and the second convex surface corresponds to the feeding position. The convex surface corresponds to the blanking position. The remaining implementation modes are the same as the first embodiment. When the manipulator moves to the position of the first convex surface, it correspondingly completes the action of grasping the bottle body, when it moves to the concave place of dipping glue, it correspondingly completes the action of dipping the bottle body with glue, and when it moves to the concave place of installation, it correspondingly completes the action of installing the bottle cap. Finish blanking when moving to the second convex surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com