Locomotive traction device disassembling and assembling method

The technology of a traction device and a disassembly and assembly method is applied in the field of disassembly and assembly of a locomotive traction device, which can solve the problems of lack of process steps, low disassembly and assembly efficiency, etc., and achieve the effects of reliable assembly process, high disassembly and assembly efficiency, and reliable disassembly process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

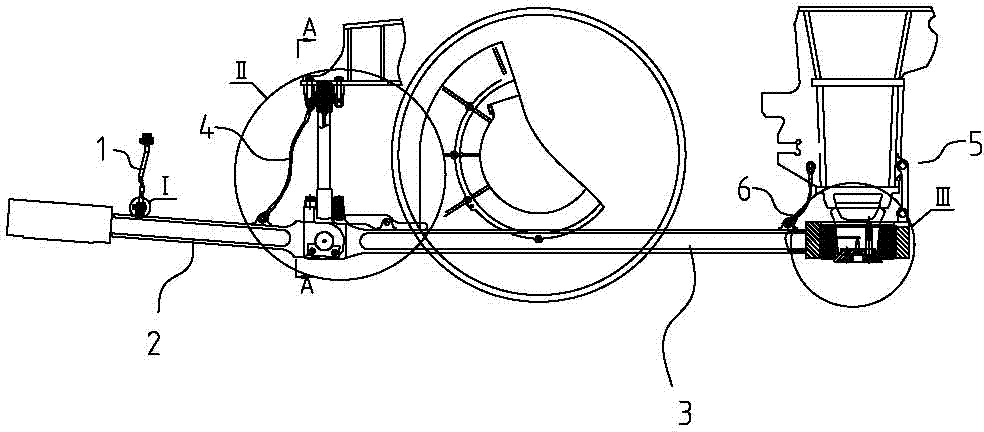

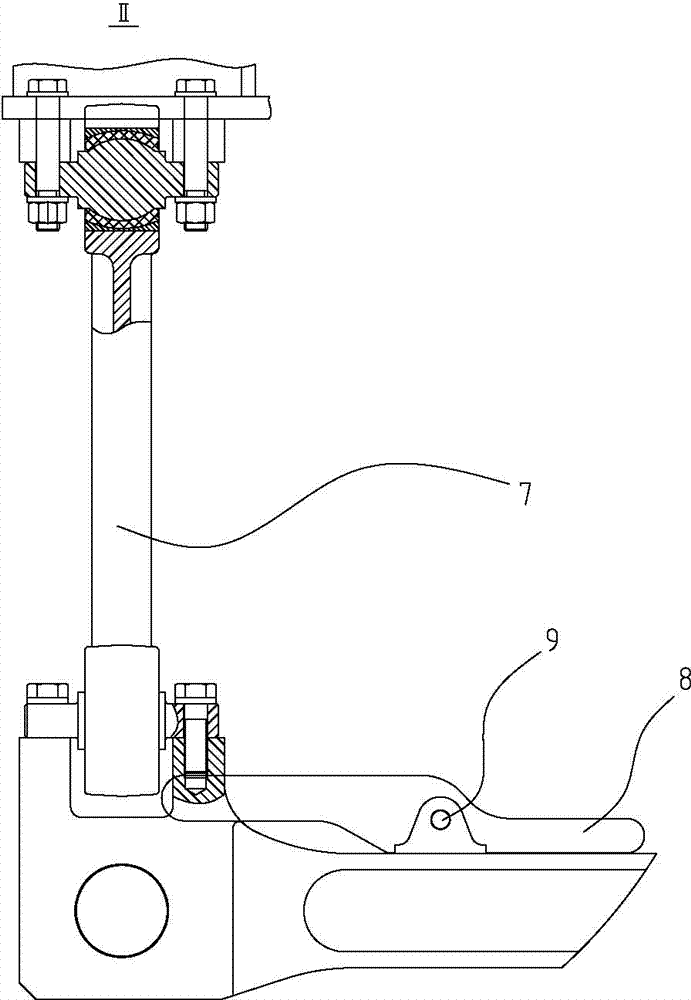

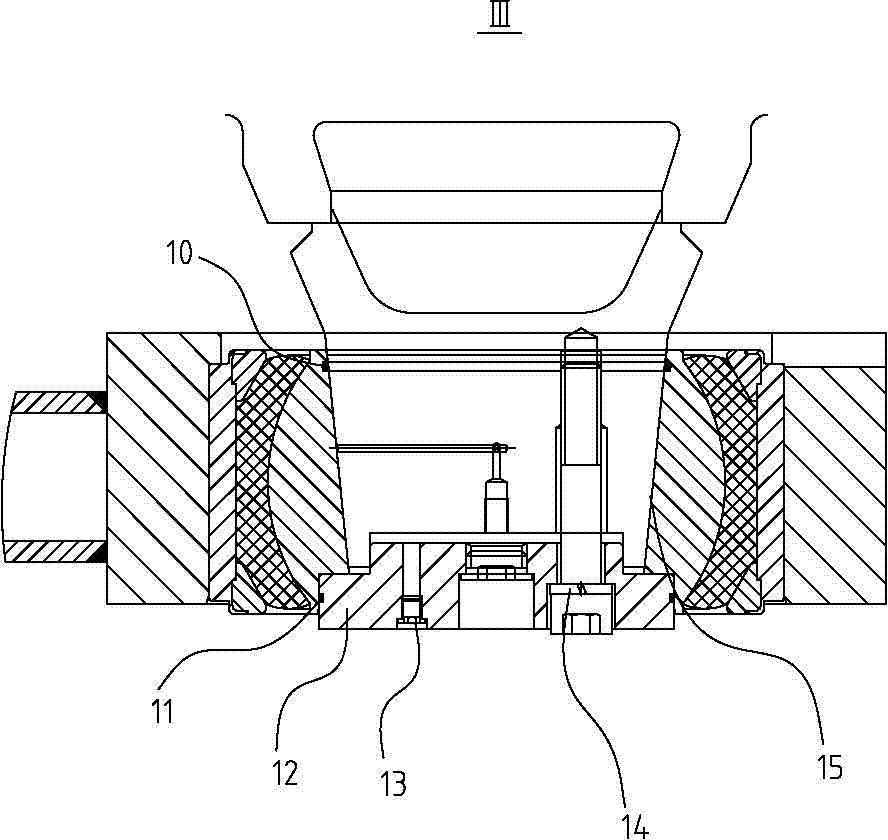

[0056] Such as Figures 1 to 4As shown, a locomotive traction device mainly includes a first drawbar 3 and a second drawbar 2 hinged to each other. One end of the first drawbar 3 is connected to a connecting rod assembly 7 and the other end is connected to a bogie fifth wheel. A second safety wire rope 1 is provided on the second drawbar 2, and a first safety wire rope 4 is provided between the second drawbar 2 and the upper end of the connecting rod assembly 7; The third safety wire rope 6. The first drawbar 3 is provided with a hanging plate 8 and a cotter pin 9 . The connecting interior of bogie traction seat 5 and first drawbar 3 is provided with O-shaped sealing ring 10 , hexagon socket screw plug 13 , cover plate 12 , sealing ring 11 located on the cover plate, spring washer 14 , and lubricating grease 15 .

[0057] Disassembly method of traction device, including disassembly process and assembly process;

[0058] The dismantling process includes the following steps: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com