Smart card connector assembly line

An assembly line and smart card technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of high labor intensity, low work efficiency, and difficulty in controlling the schedule of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

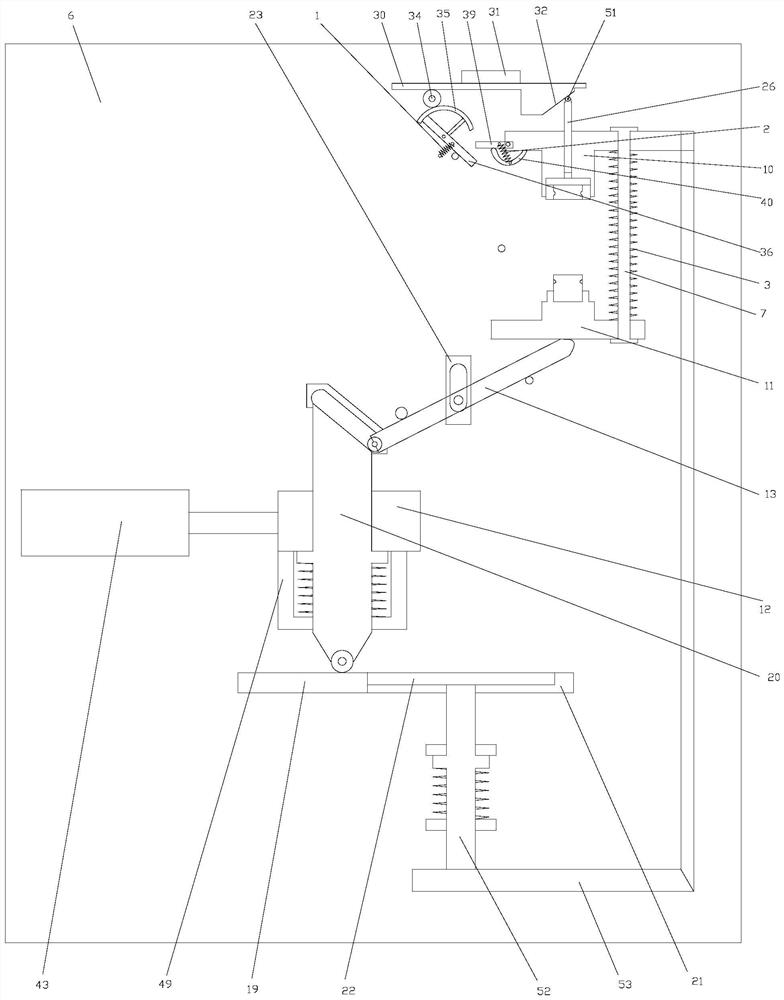

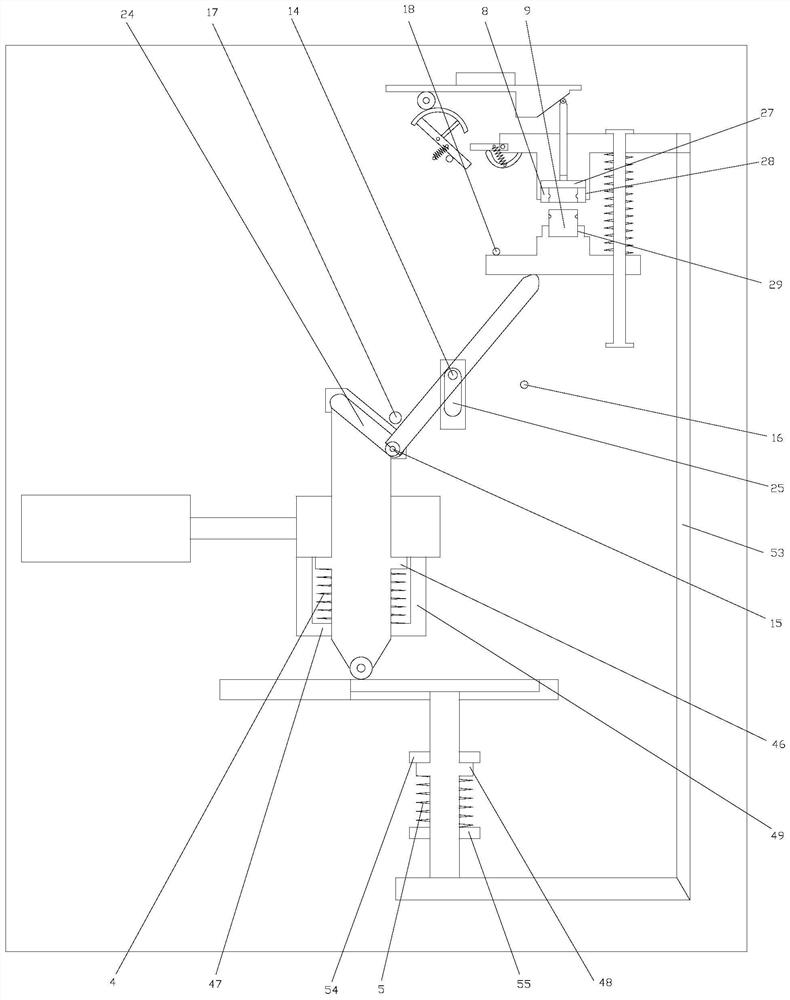

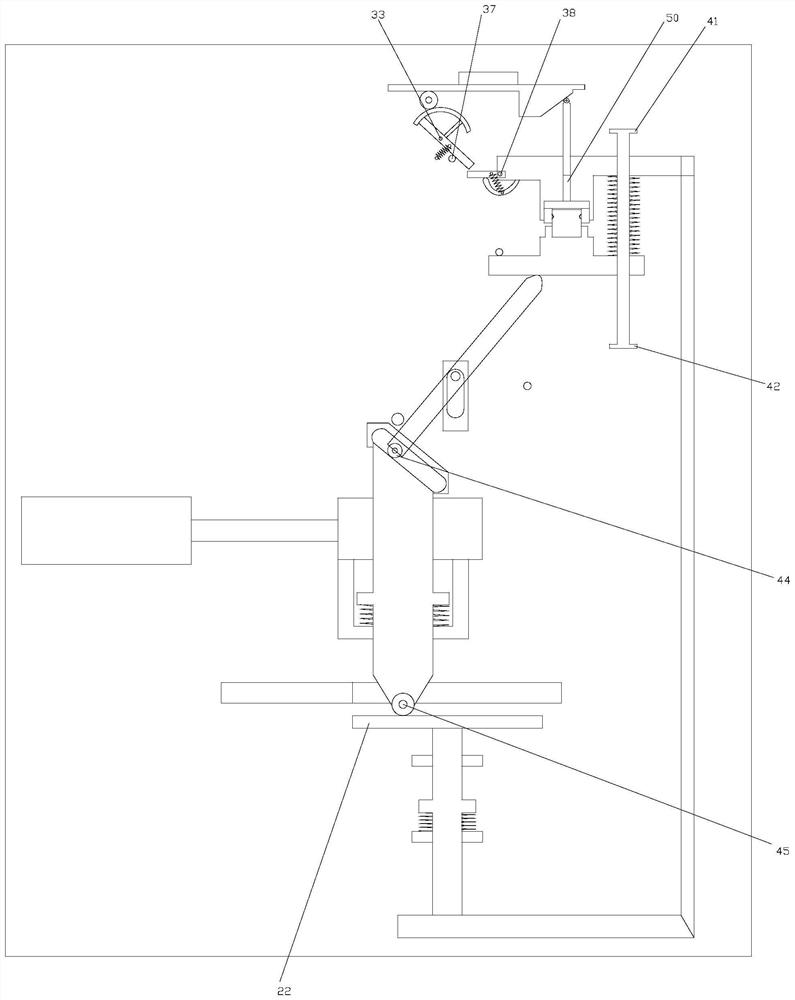

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0015]As shown in the figure, the assembly line of the smart snap connector of the present invention includes a base 6 on which a guide rod 7 is provided, and the guide rod 7 is sequentially sleeved with an upper sliding table 10 for accommodating the first workpiece 8 from top to bottom. With the sliding table 11 for accommodating the second workpiece 9, the sliding direction of the upper sliding table 10 and the sliding table 11 is opposite. The upper sliding table 10 mentioned here is opposite to the moving direction of the sliding table 11. When the sliding table 11 is closed, the two move closer to the middle position of the guide rod 7, and when the upper sliding table 10 and the sliding table 11 are parted, the two spread toward the two ends of the guide rod 7; the upper sliding table 10 and the sliding table 11 pass through elastic limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com