Seat back structure of vehicle seat and method for inhibiting head tremor damage for seat back of vehicle seat

A technology for seat backs and vehicles, which is applied to vehicle seats, vehicle parts, special positions of vehicles, etc., can solve the problems of occupants easily feeling the bottom, and the elastic deformation of support plates is limited, etc., and achieves excellent applicability and parts. The effect of reducing the number of objects and simplifying the structure and miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

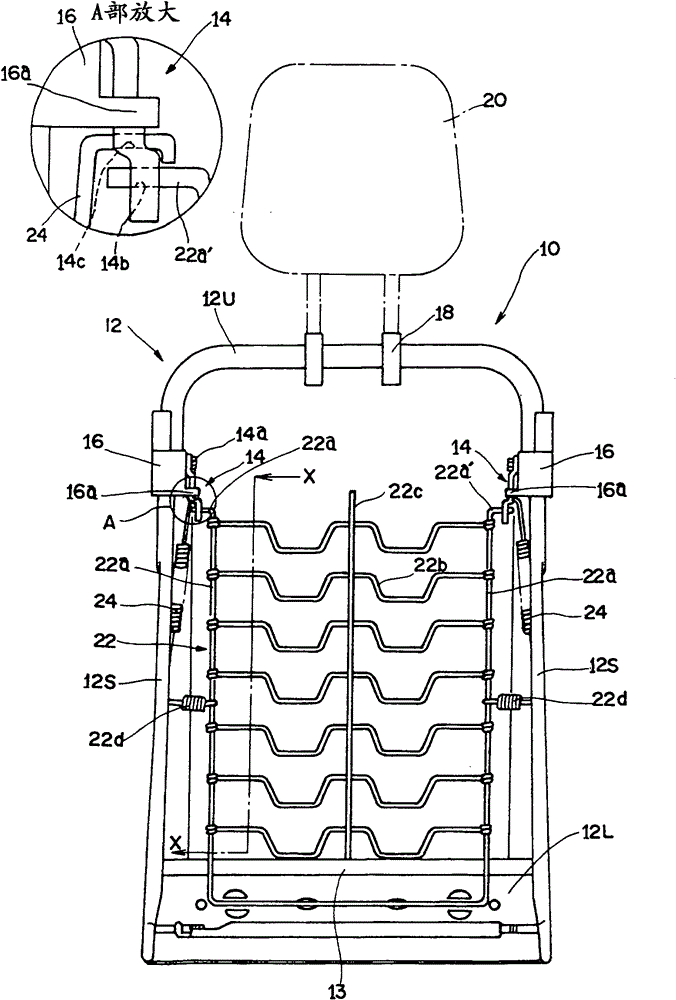

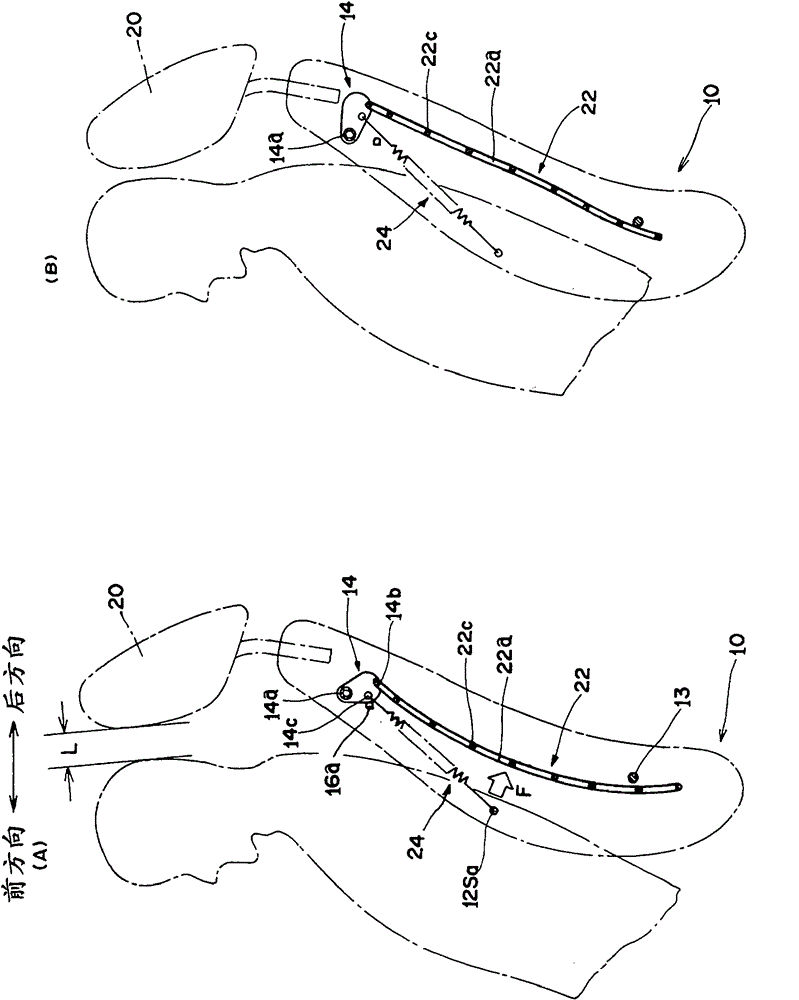

[0050] figure 1 It is a schematic front view showing a seat back structure of an embodiment of the present invention. in addition, figure 2 (A), (B) represent along figure 1 The movement of the main components before and after the application of the impact load on the cross section of the line X-X in , and the components not related to the movement of the support plate are omitted to avoid complicating the drawing.

[0051] Such as figure 1 As shown, in the seat back 10 of the vehicle seat of the present invention, the seat back frame 12 has a substantially inverted U-shaped upper portion composed of a pair of left and right side members 12S and pipes connecting the left and right side members above. The member 12U and the lower member 12L connecting the left and right side members below are formed in a rectangular frame shape. Furthermore, a pair of tur...

Embodiment 2

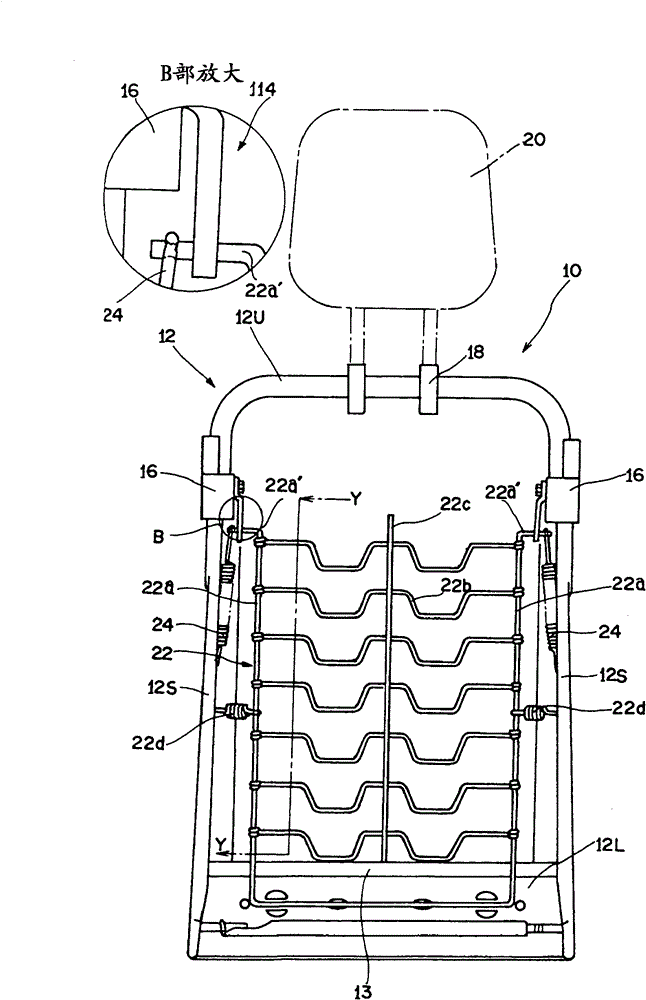

[0087] image 3 , Figure 4 The seat back structure of another example (Example 2) is shown. here, image 3 , Figure 4 With above-mentioned embodiment (embodiment 1) figure 1 , figure 2 (A), (B) corresponding, image 3 A schematic front view showing the seat back structure of Embodiment 2, Figure 4 (A), (B) represent along image 3 The movement of the main constituent parts before and after the impact load is applied on the cross-section of the line Y-Y. In addition, in Figure 4 (A), (B), and figure 2 (A) and (B) Similarly, components not related to the movement of the support plate are omitted to avoid complicating the drawings.

[0088] In Embodiment 1, the left and right frames of the supporting plate move backward with the rotation of the rotating link, but in Embodiment 2, the following point is different in that a guide hole with a guide hole is provided instead of the rotating link. Fixed guide plate, the frame body upper end of support plate can move a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com