Frame structure, rear frame structure and body of automobile

A technology of frame structure and rear frame, applied in the directions of substructure, superstructure, superstructure sub-assembly, etc., can solve the problem of inability to set up, unsatisfactory driving variant structure of body structure, lack of sufficient space for accommodating components, etc. problem, to achieve the effect of large structure space and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

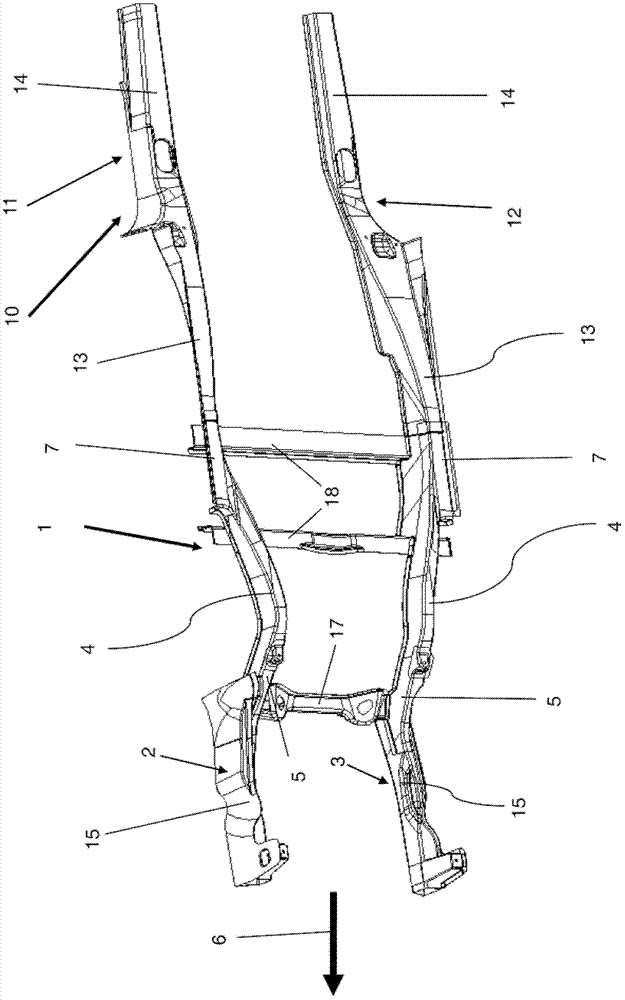

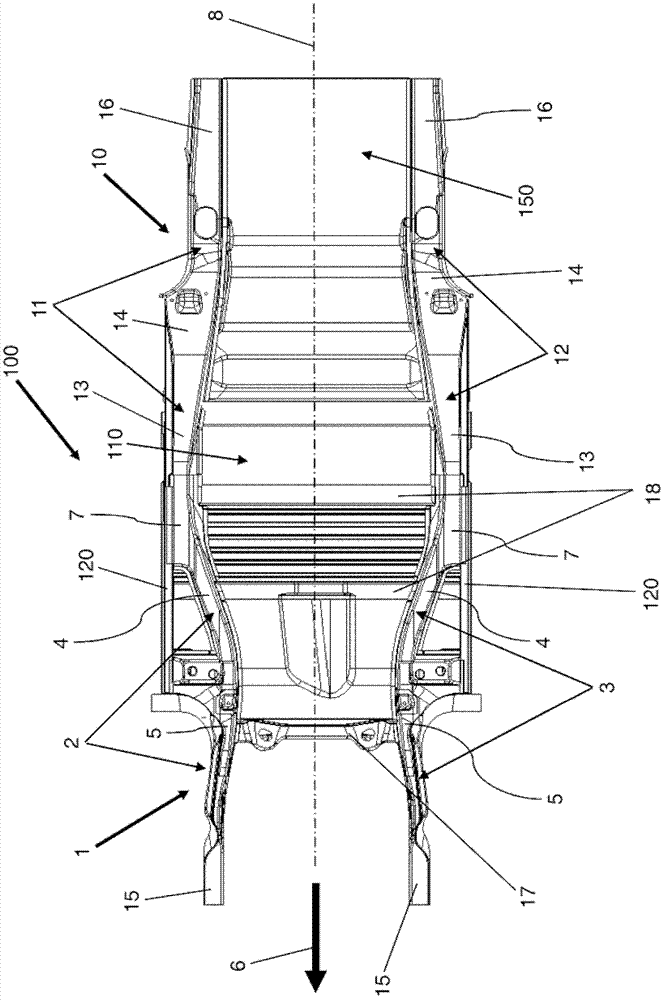

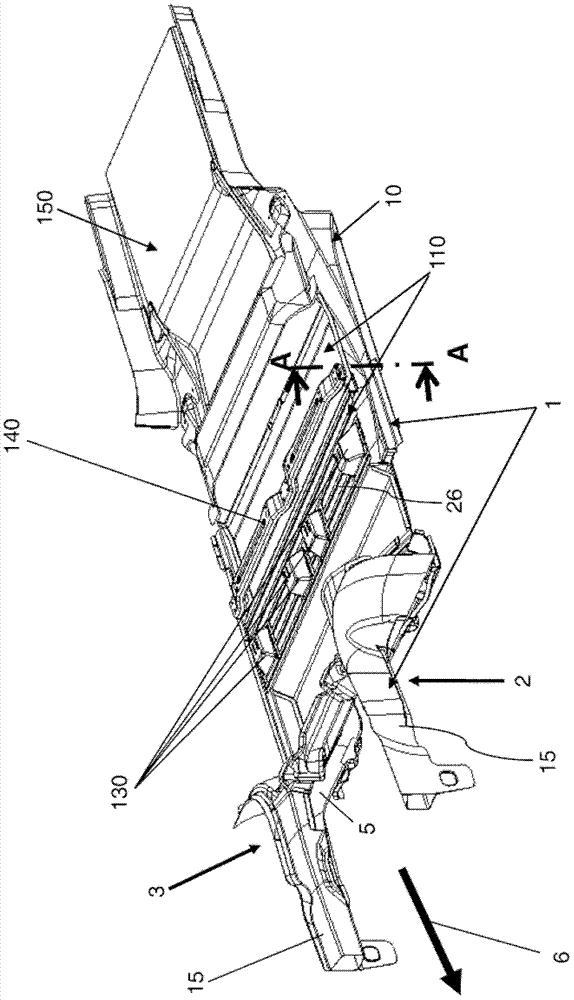

[0049] figure 1 The side members 2 , 3 of a frame structure 1 are shown schematically, which preferably form the front frame structure of a (not shown) motor vehicle body. The longitudinal beams 2, 3 each have a first longitudinal beam section 4 and a second longitudinal section 5, which are formed at an angle to each other such that a (not shown) In the state of the motor vehicle, the first longitudinal section 4 is located substantially horizontally below the (not shown) front floor of the vehicle body, while the second longitudinal section 5 extends substantially upwards and viewed in the direction of travel 6, the first The longitudinal section 4 is arranged behind the second longitudinal section 5 .

[0050] The side members 2 , 3 each additionally have a further longitudinal section 15 which, in the installed state of the front frame structure 1 , protrudes into the engine compartment of the motor vehicle (not shown) and is arranged here preferably in the Between engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com