Tube cutter for glass tube

A glass lamp tube and tube cutting machine technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of broken glass tubes, low efficiency, unstable product quality, etc. The effect of inaccurate length and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

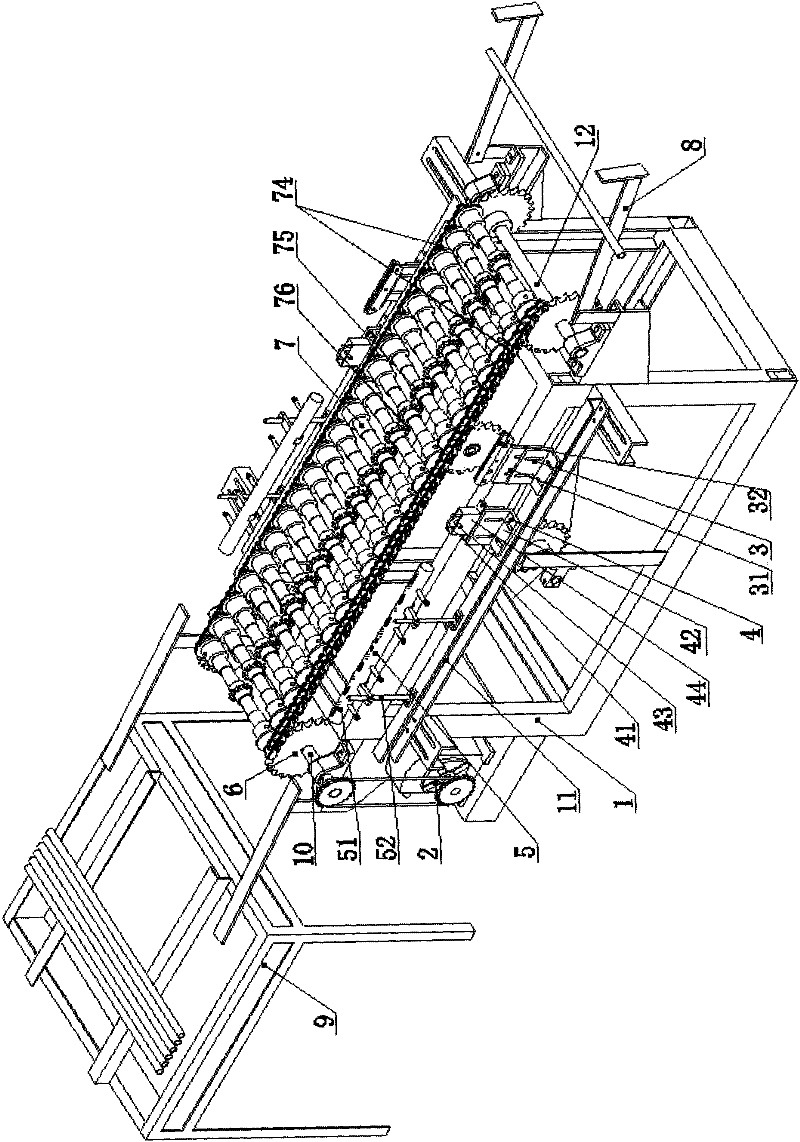

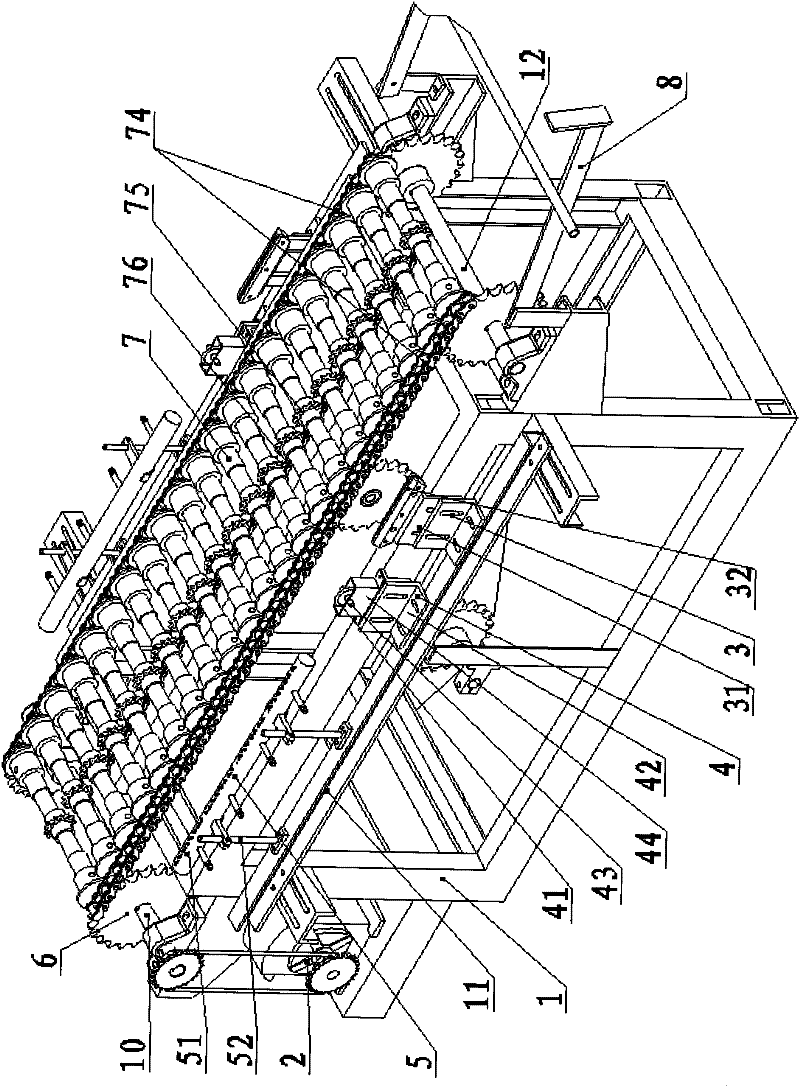

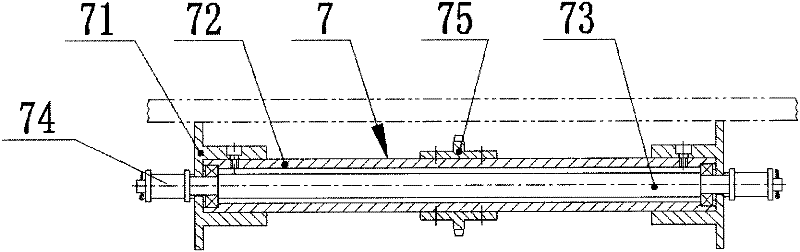

[0014] Such as figure 1 , figure 2 As shown, the glass lamp tube cutting machine of the present invention includes a frame 1, a transmission device 2, a cutting fire device 3, a cutter device 4, a round mouth fire device 5, a driving sprocket 6, a lamp tube rotation and translation device 7, an upper tube The pipe rack 8 and the lower pipe placement rack 9; wherein, the frame 1 is a cuboid, and its two ends are respectively equipped with a driving shaft 10 and a driven shaft 12, and the transmission device 2 is installed on the left lower side of the frame 1, and passes through The sprocket transmission pair is connected with the driving shaft 10 to drive the machine to run. A group of driving sprockets 6 are respectively installed at the two ends of the driving shaft 10 and the driven shaft 12, and are respectively connected to each other thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com