LED device with transition substrate and packaging method thereof

A technology for LED devices and transition substrates is applied in the field of LED devices with transition substrates and their packaging, which can solve the problems of limitation, high cost, and inability to produce devices, and achieve the effects of low cost, reduced stress, and high chip reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

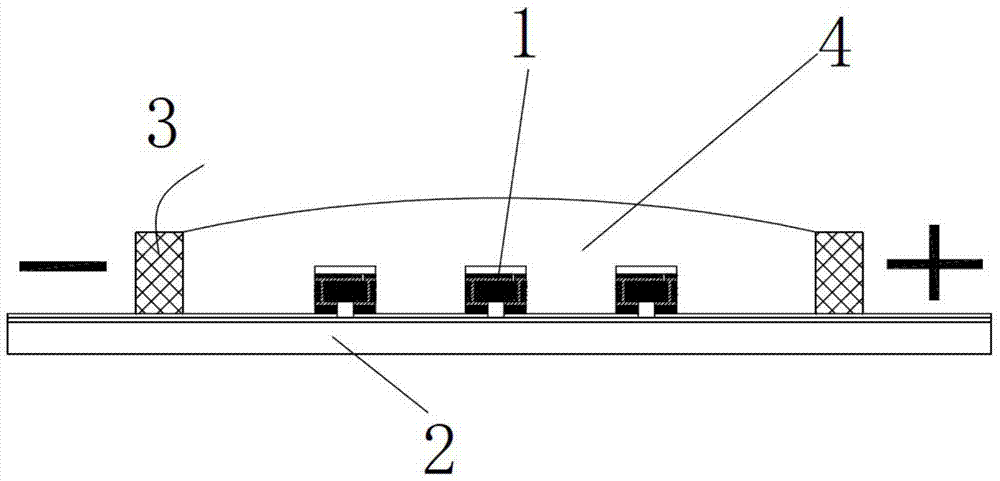

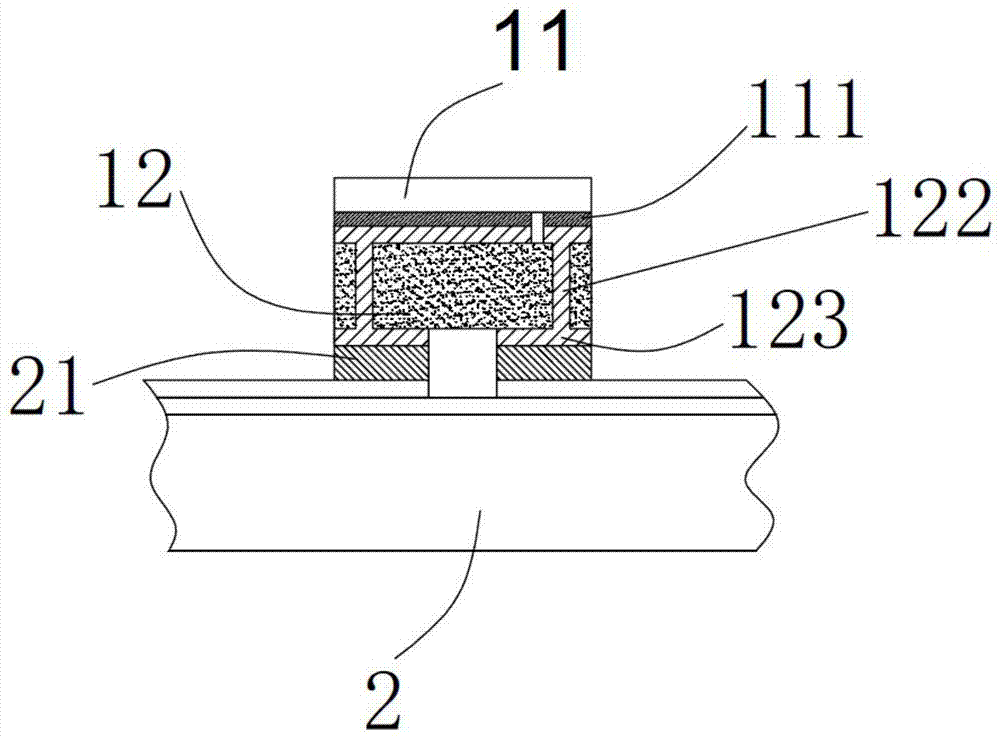

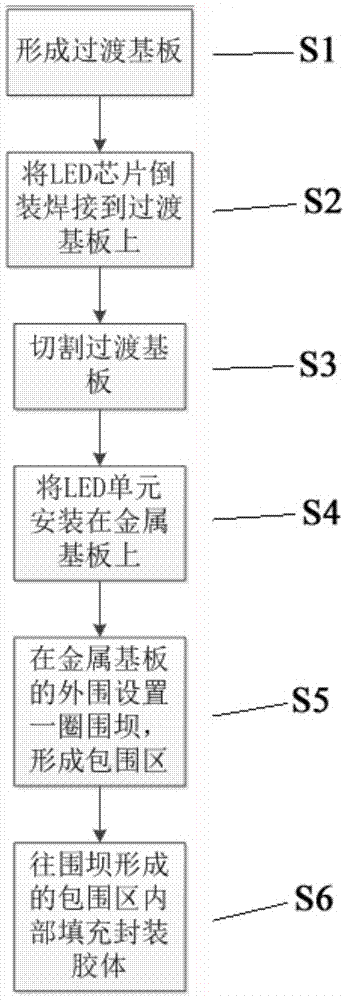

[0041] Please also see figure 1 and figure 2 ,in, figure 1It is a cross-sectional structural schematic diagram of an LED device with a transition substrate in the present invention, figure 2 yes figure 1 The shown schematic diagram of the cross-sectional structure of the LED unit arranged on the metal substrate.

[0042] Such as figure 1 As shown, the LED COB device with a transition substrate of the present invention includes: at least one LED unit 1 , a metal substrate 2 , a dam 3 and an encapsulant (not shown in the figure). The LED unit 1 is welded on the metal substrate 2 and electrically connected thereto. The dam 3 is arranged on the edge of the metal substrate 2 and surrounds all the LED units 1 on the metal substrate to form an enclosing area 4 for packaging. The encapsulant is filled in the surrounding area 4 and covers and seals all the LED units 1 inside.

[0043] Specifically, such as figure 2 As shown, the LED unit 1 includes an LED chip 11 and a trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com