Zoom lens

A zoom lens and lens barrel technology, applied in the field of zoom lenses, can solve the problem of the mirror chamber being unable to maintain a stable position, and achieve the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to describe in detail the structure, features and effects of the present invention, a preferred embodiment is enumerated and described as follows in conjunction with the accompanying drawings, wherein:

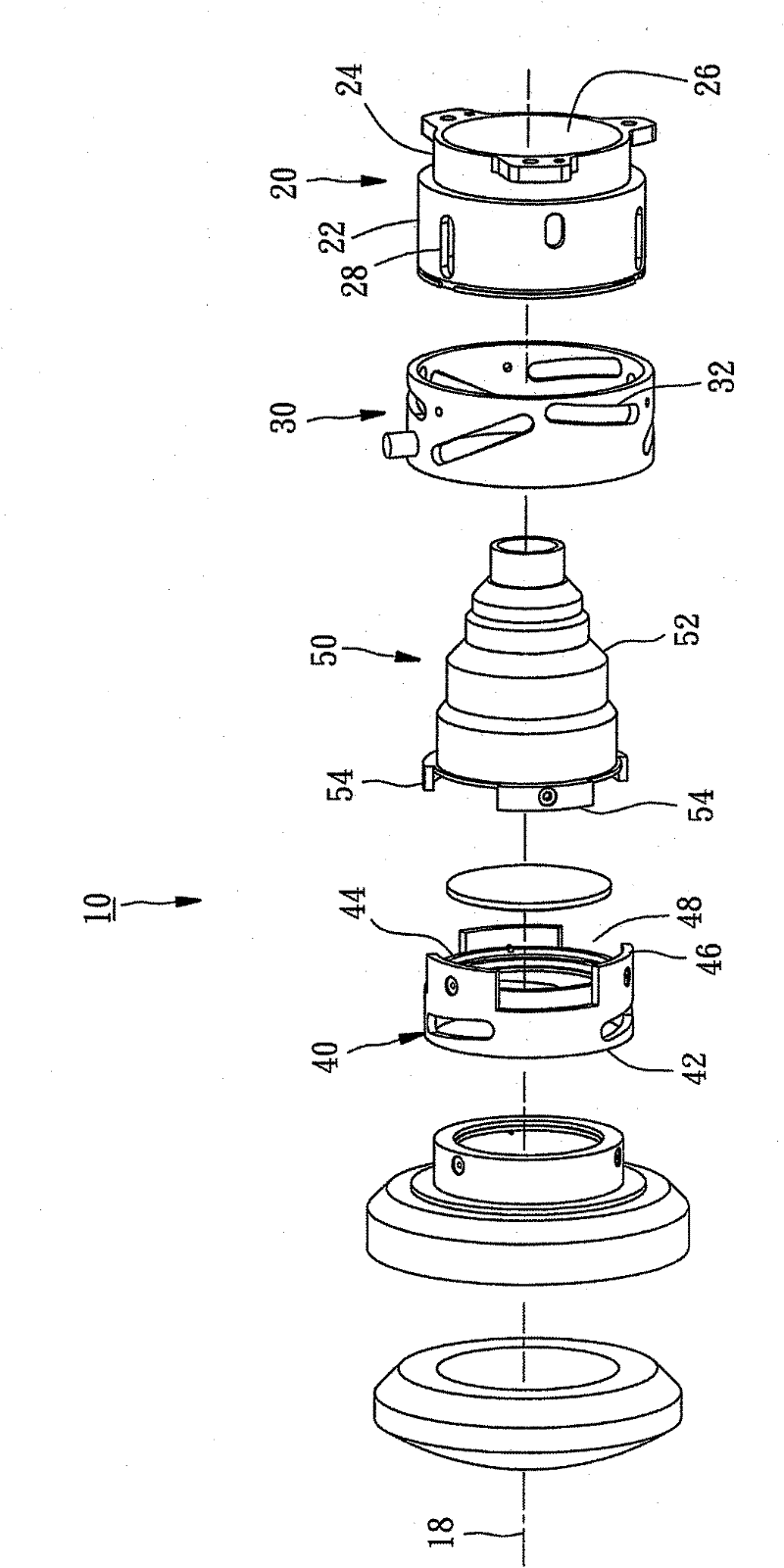

[0017] figure 1 It is an exploded perspective view of a preferred embodiment of the present invention.

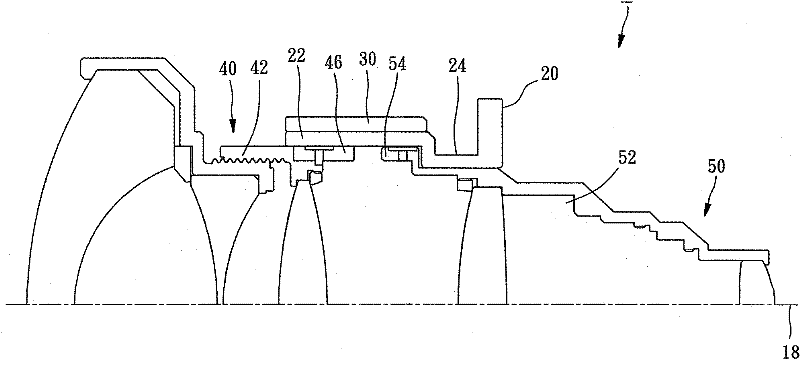

[0018] figure 2 It is a partial sectional view of a preferred embodiment of the present invention, wherein the first mirror chamber and the second mirror chamber are separated from each other.

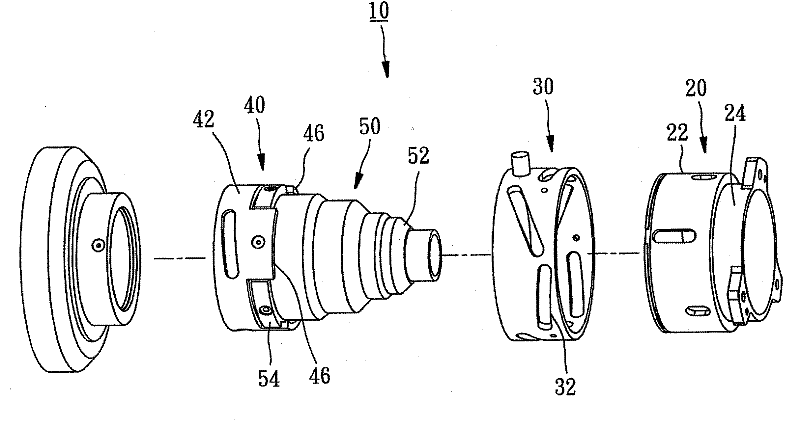

[0019] image 3 It is a three-dimensional partial exploded view of a preferred embodiment of the present invention, wherein the fitting portion of the first mirror chamber is inserted into the fitting groove of the second mirror chamber.

[0020] Figure 4 It is a partial cross-sectional view of a preferred embodiment of the present invention, wherein the fitting portion of the first mirror chamber is inserted into the slot of the second mirror chamber.

[002...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap