Process unit and image-forming device using process unit

A technology for processing unit and image, applied in the direction of electric recording process applying charge pattern, equipment for applying electric recording process of charge pattern, electric recording technique, etc. increased pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

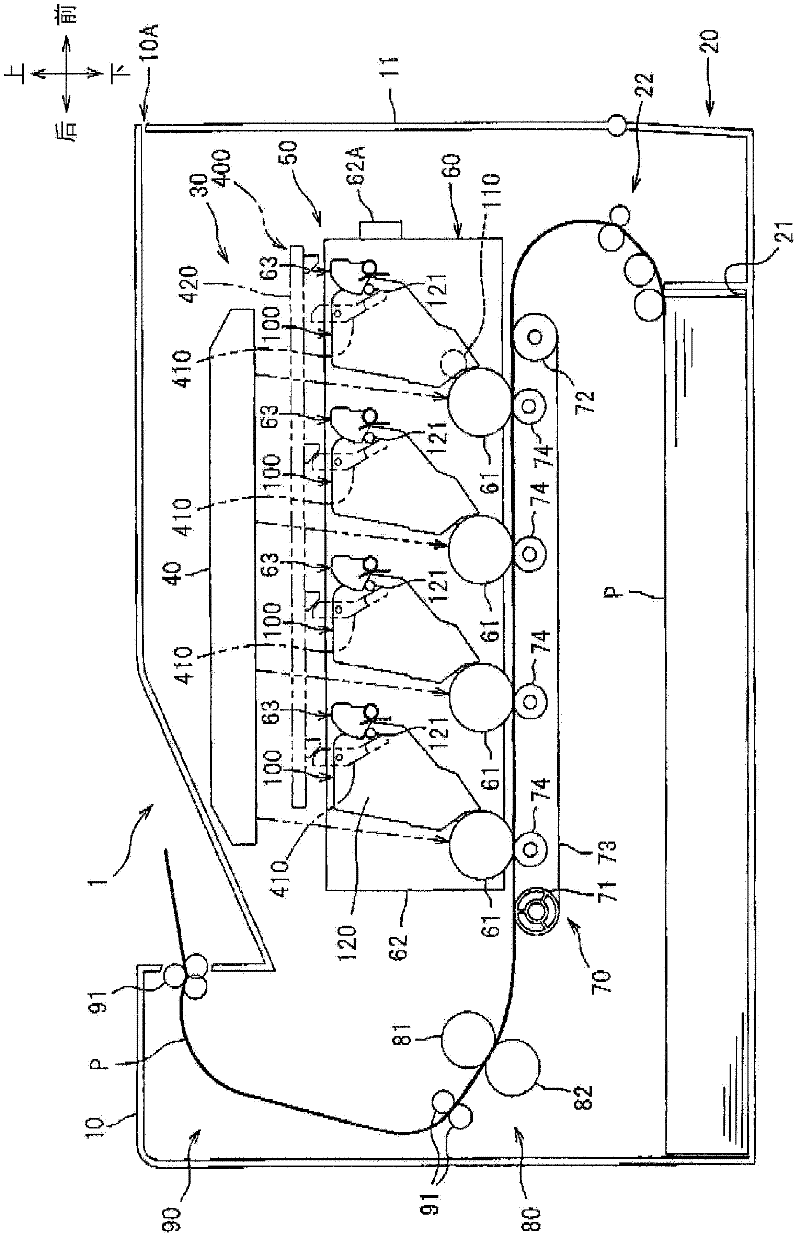

[0019] First, refer to figure 1 A color printer 1 according to an embodiment of the present invention is described.

[0020] Throughout the specification, it is assumed that the color printer 1 is arranged at a position where it needs to be used, and the terms "up", "down", "above", "below", "above", "below", "below", "right" , "left", "front" and "rear" etc. will be used throughout the specification. In use, the color printer 1 is arranged as figure 1 at the position shown. Specifically, figure 1 The right side of is called the front side, and figure 1 The left side is called the posterior side. figure 1 The far side in will be referred to as the right side, and figure 1 The near side in will be referred to as the left side.

[0021] Such as figure 1 As shown, the color printer 1 includes a main body 10 provided with a pivotally movable front cover 11 . In the main body 10, a sheet supply unit 20, an image forming unit 30, and a sheet discharge unit 90 are provided. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com