Cast-weld fixture for storage battery

A technology of casting and welding fixtures and storage batteries, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems that the bridge structure cannot pass through the fixtures, and the production is inconvenient, so as to reduce production costs and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

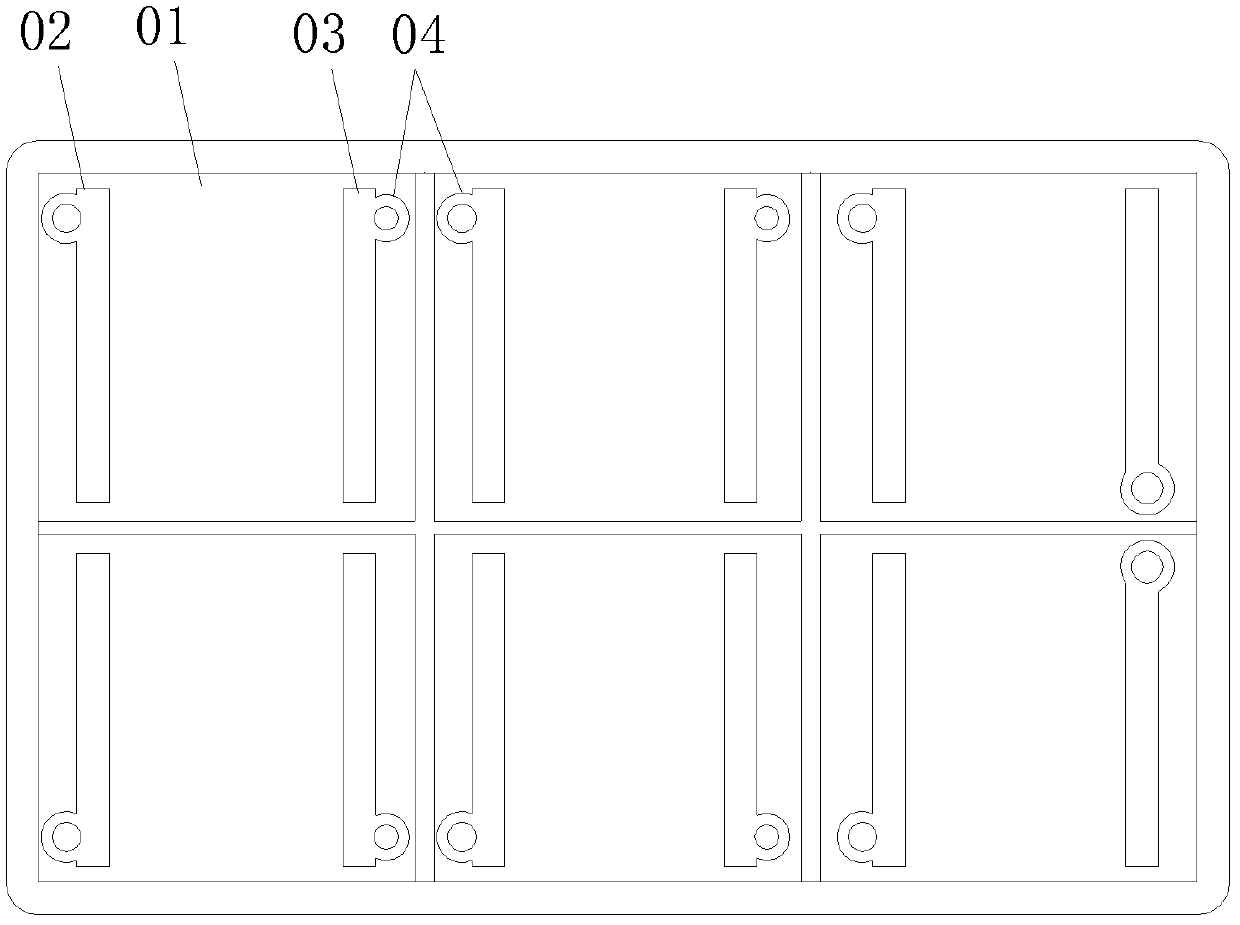

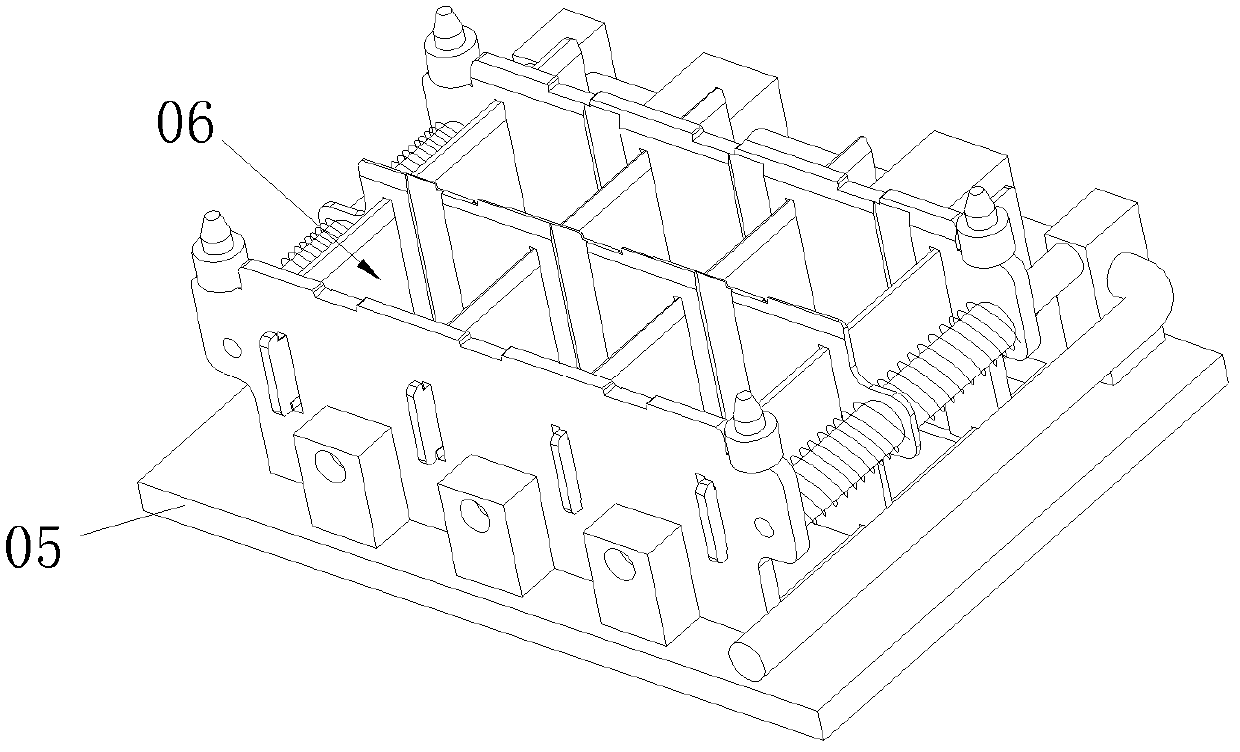

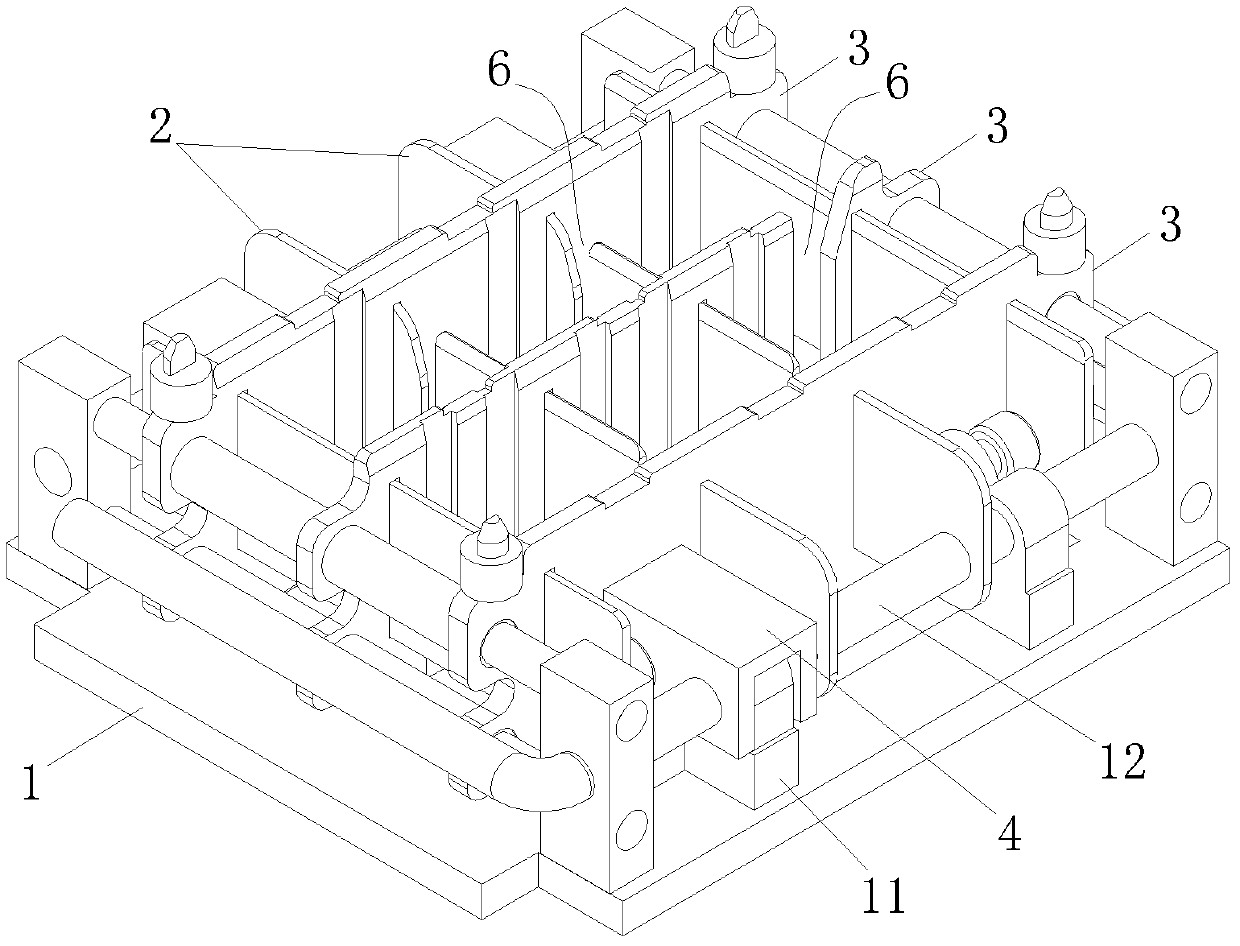

[0019] refer to image 3 , 4 5. The present invention provides a battery casting and welding fixture, including a fixture base plate 1, a clamping plate assembly and a clamping arm assembly for driving the clamping plate assembly to clamp and fix the battery cell, and the clamping plate assembly includes a fixing clamping plate 2 As with the movable splint 3 , the fixed splint 2 and the movable splint 3 are alternately arranged to form a plurality of well-shaped cavities capable of accommodating battery cells. The clamping arm assembly includes a cushion block 11 fixed on the clamp bottom plate 1, on which is transferred a rocker arm 12 and a cam clamp block 4 driven to rotate by the rocker arm 12, and the rocker arm 12 drives the cam clamp block 4 to push the most External movable splint 3; the end of the cam clamp block 4 is transferred with a roller 41 through a pin, and the roller 12 pushes the movable splint 3 when the rocker arm 12 drives the cam clamp block 4; In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com