Plug shell assembly and plug with same

A technology of plug housing and components, which is applied in the direction of electrical components, optical waveguide coupling, and parts of connecting devices, etc. It can solve the problems of easy loosening of connecting nuts, and achieve the effect of easy loosening and prevention of loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

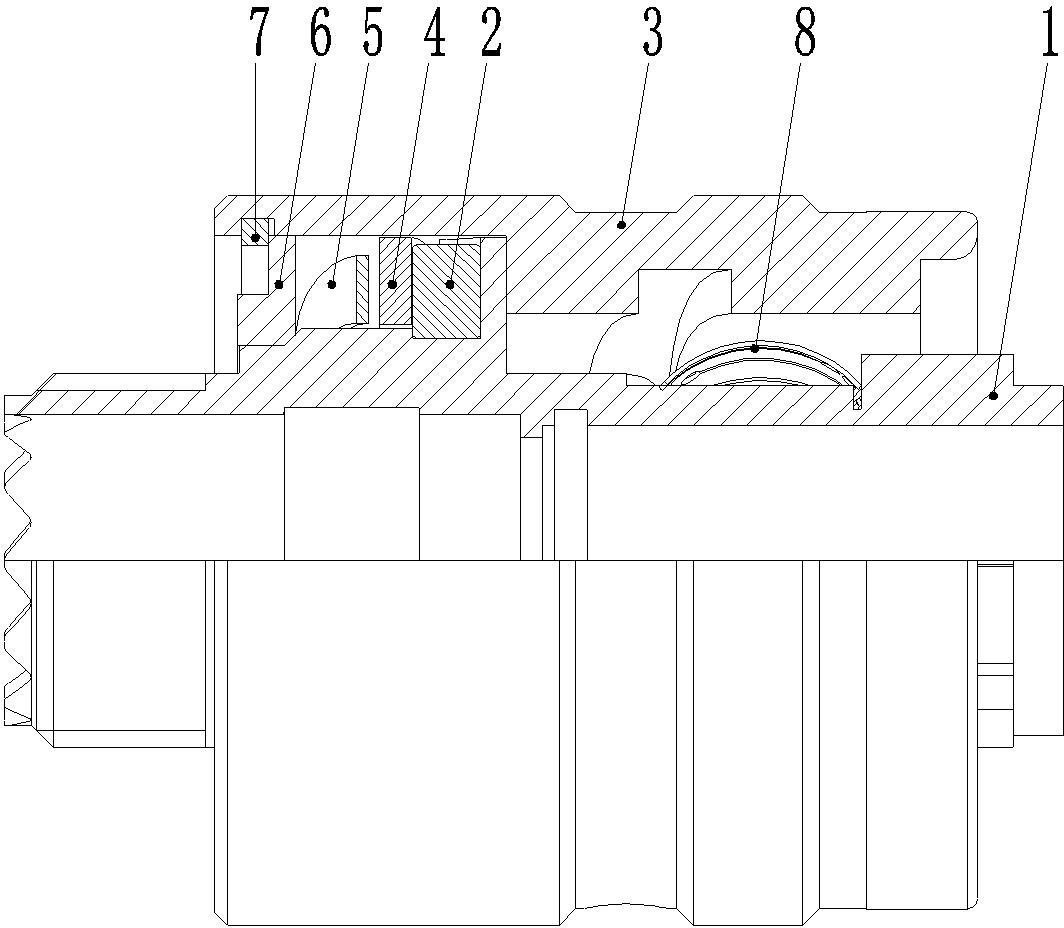

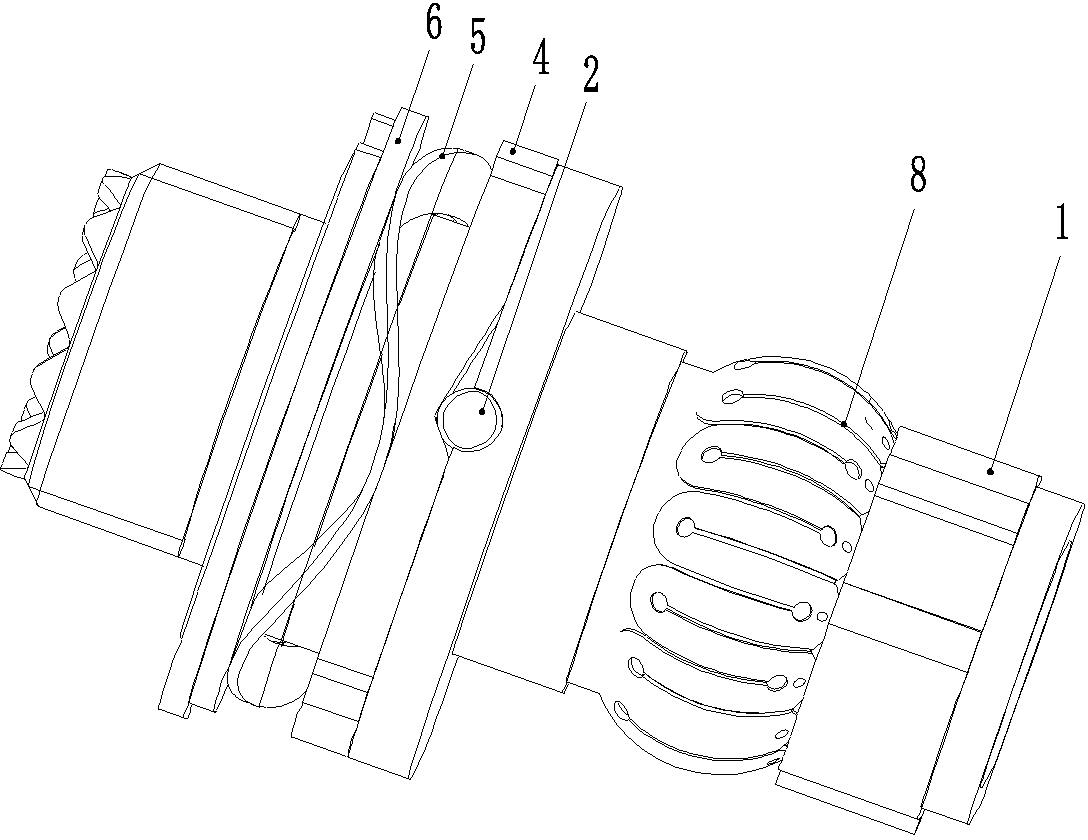

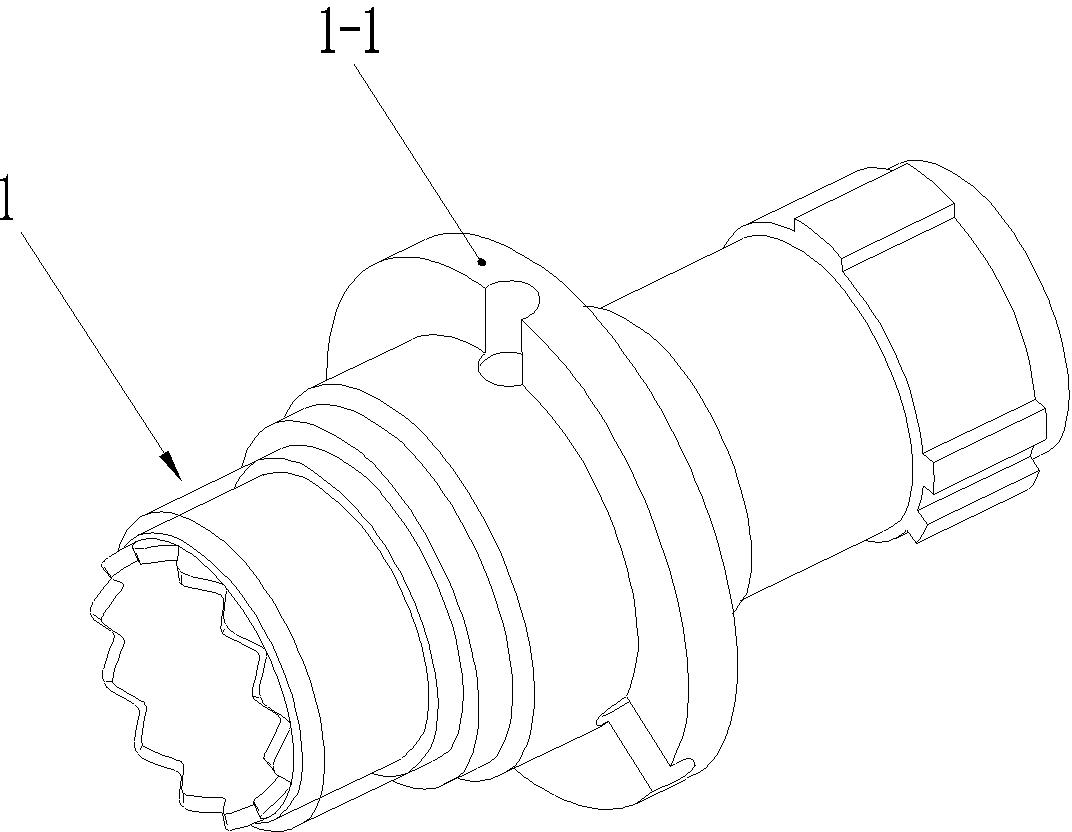

[0031] Embodiment 1 of the plug housing assembly of the present invention, as Figure 1-8 As shown, there is a plug housing 1, an eversion edge 1-1 is provided between the two ends of the plug housing 1 and a stop post 2 is provided behind the eversion edge 1-1. In this embodiment, the stop post 2 There are three, and the three retaining columns 2 are evenly distributed in the circumferential direction of the plug housing 1 and rotate with the plug housing 1 around their respective axes. Extending outwardly, the rear side of the everted edge of the plug housing 1 is provided with grooves corresponding to the blocking posts 2 one by one, and each blocking post 2 is embedded in the corresponding groove and its rear side protrudes backward from the plug casing The rear side of the valgus edge of 1; the plug housing 1 is rotatably provided with a connecting nut 3, and the front end of the connecting nut 3 is provided with an internal thread, and the internal thread at this place i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com