Direct current/direct current (DC/DC) power supply test fixture

A test fixture, DC power supply technology, applied in the direction of transducer housing/cabinet/stand, microphone structure association, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

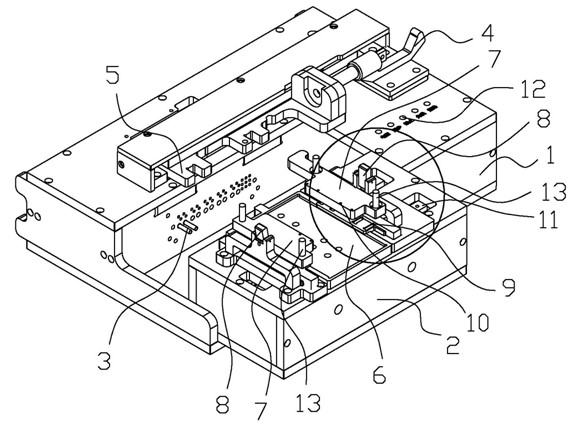

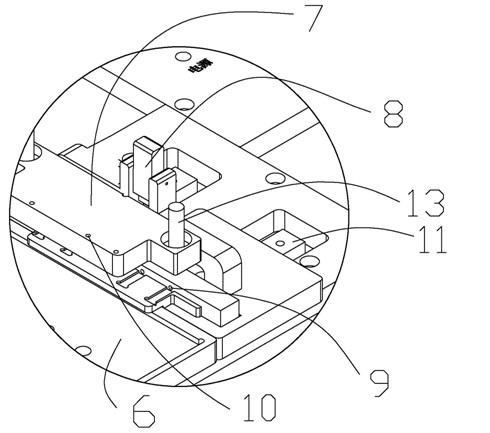

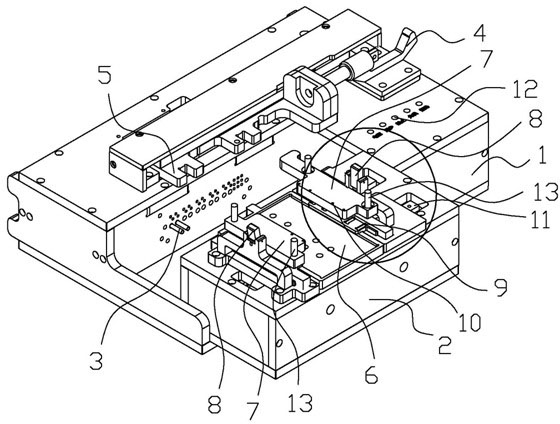

[0021] The present invention will be further described below with reference to the accompanying drawings.

[0022] like figure 1 , figure 2 As shown, the DC / DC power supply test fixture of the present invention includes a female fixture 1 and a sub-fixture 2 that is matched and connected to the female fixture 1 through the pin sockets of the crown spring structure (that is, the crown spring connector 3). The fixture 1 is connected to the test instrument or system through the wiring terminals on the back, and the sub-fixture 2 is provided with a bearing platform 6 for fixing the power supply product under test and placing the power supply product under test. The mechanism and the vertical fixing mechanism for fixing the vertical direction of the power supply product, wherein the horizontal fixing mechanism includes two horizontal fixing plates located on both sides of the bearing platform 6, one of which is fixed on the sub-clamp 2, and the other is fixed on the bearing platf...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap