Control method for self-adaption compensation of elongation of planisher

A technology of self-adaptive compensation and control method, applied in tension/pressure control, rolling force/roll gap control, metal rolling, etc., which can solve the problems of compensation control in acceleration and deceleration stage, poor elongation stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

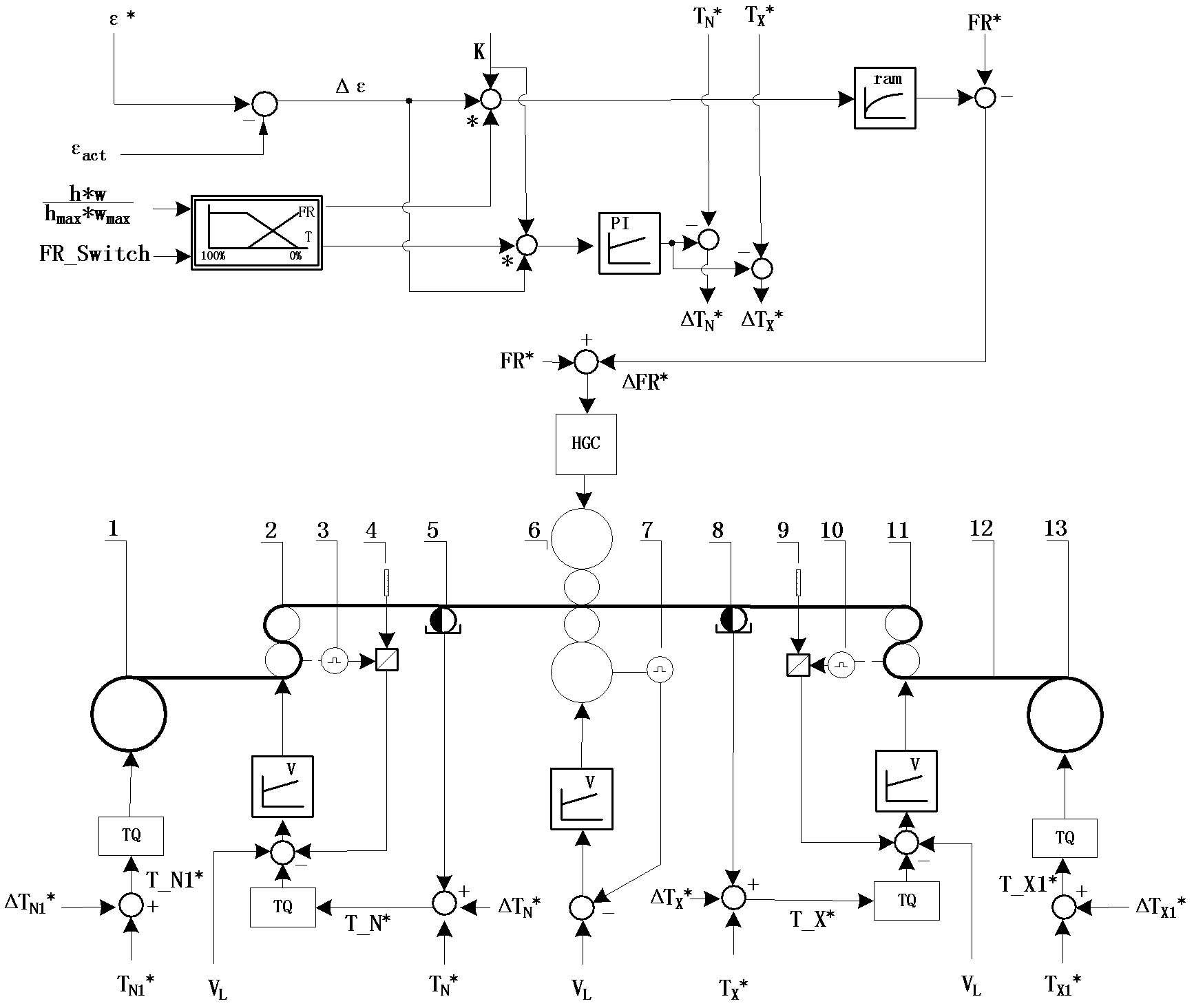

[0034] Embodiment 1: Self-adaptive compensation control method for elongation rate of temper mill

[0035] Specifically, a method comprising the following steps is adopted:

[0036] 1. Definition of flat elongation:

[0037] The basic meaning of leveling elongation is different from conventional rolling. Leveling is essentially a small deformation rolling, which is a very important production process in the cold rolling process. Elongation is one of the most basic process parameters in skin-passing. The reduction in the skin-passing pass is very small, and the strip thickness deviation between the exit side and the entrance side of the skin-passing machine can hardly be measured with a thickness gauge. Therefore, the measuring tape The method of steel elongation as an equivalent value for measuring its thickness change.

[0038] Elongation is defined as the ratio of the difference between the strip thickness before leveling and the strip thickness after leveling to the strip...

Embodiment 2

[0072] Example 2: Application of adaptive compensation control method for elongation rate of temper mill

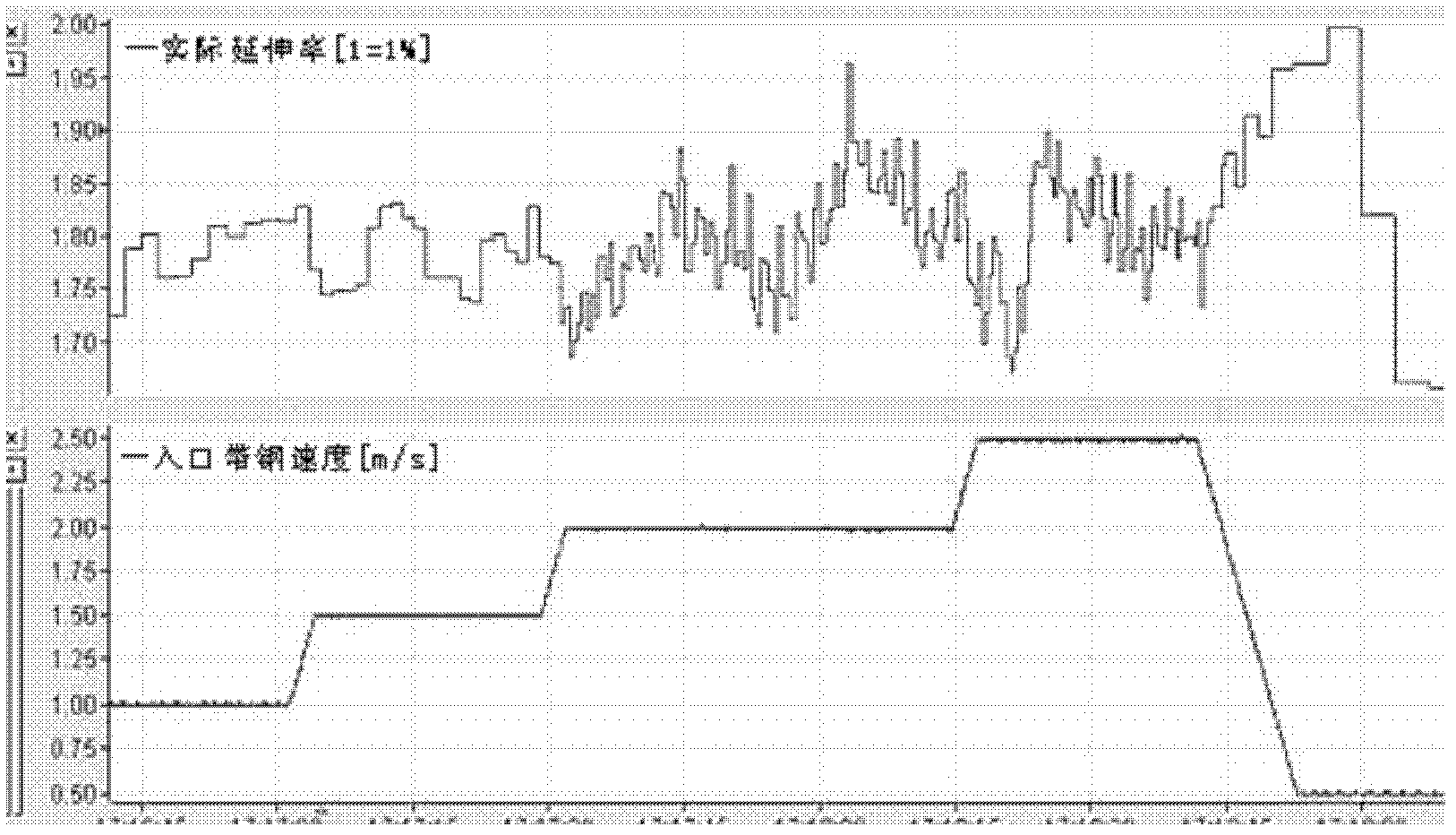

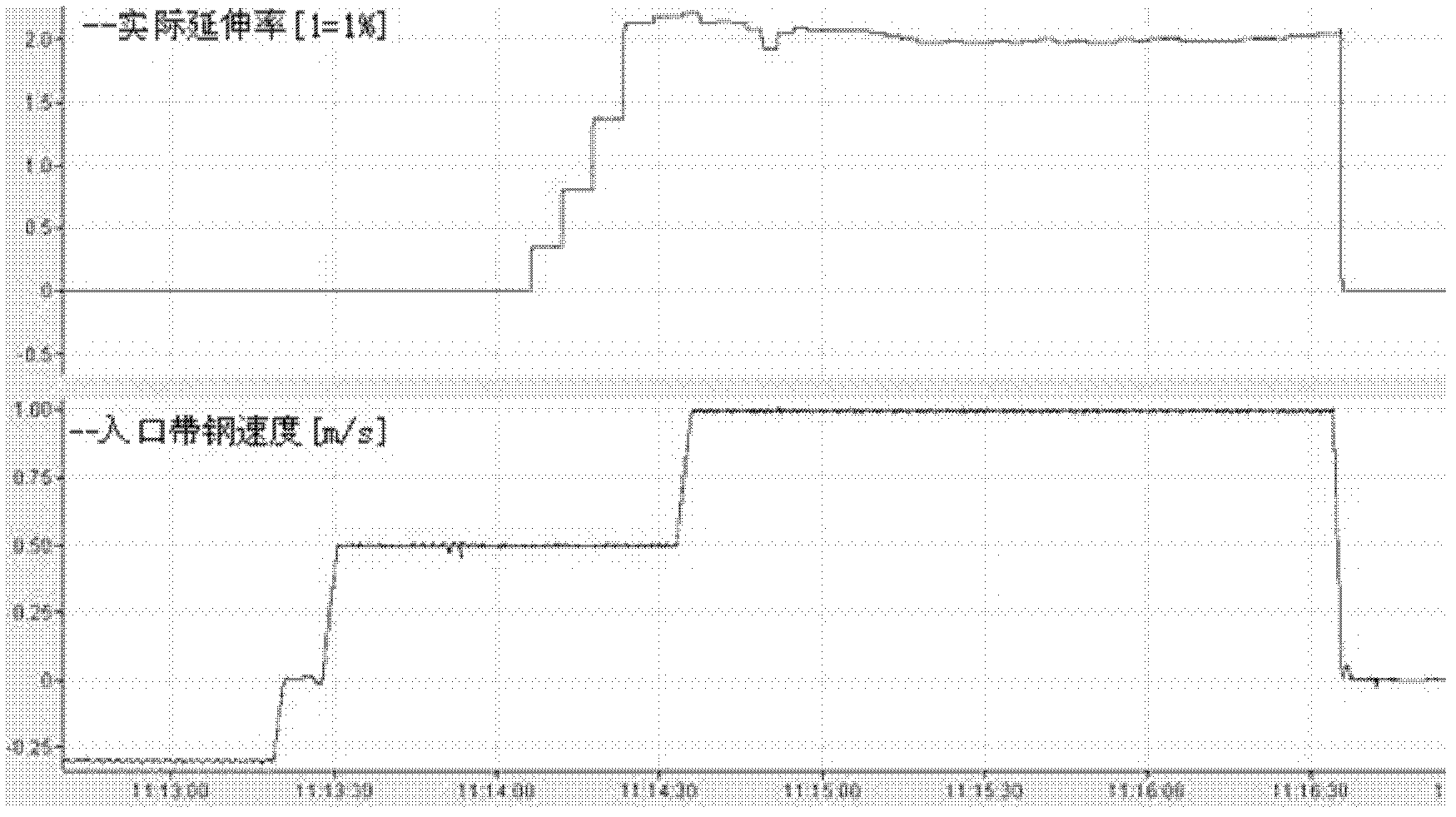

[0073] When the leveling unit is running at a low speed with acceleration and deceleration, both the installation accuracy of the equipment and the response characteristics of the laser speedometer will cause fluctuations in the elongation control accuracy, such as figure 2 As shown, we increase the elongation rate adaptive compensation control link according to the method described in Embodiment 1, and the specific steps are as follows:

[0074] (1) The self-adaptive compensation program for the elongation of the temper mill receives the set value of the rolling force FR * , Tension setting value before and after the tempering machine and Elongation setting value ε * ;

[0075] (2) Measure the rolling force FR through the pressure head of the temper mill act , Tension meter measured T Nact and T Xact , rotary encoder and laser velocimeter to measure the strip e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com