Special mechanism for bending aluminum profile presser-foot of inner bus decoration

A technology for aluminum profiles and interior decoration, which is applied in the field of production equipment for passenger car interior decoration, can solve the problems of low grade of finished products, low yield of finished parts, labor intensity and difficulty, etc., so as to improve quality and yield , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

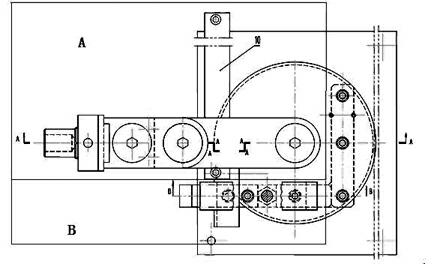

[0012] Example: as figure 1 As shown, the appearance structure of this special mechanism for bending the presser foot of aluminum profiles for interior decoration of passenger cars is shown in the figure, and the processing A area and the processing B area are fixedly connected with the chassis 17 respectively.

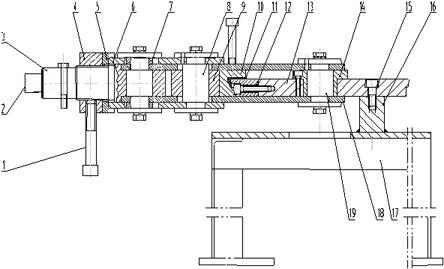

[0013] like figure 2 As shown, one end of the connecting shaft in the processing area A is equipped with a threaded wrenching pry tube 1, and the other end of the connecting shaft 3 is connected to the sliding shaft through the wrenching bolt 1, compression nut 4 and compression washer 5, and the sliding shaft is connected to the sliding shaft. The upper and lower connecting plates 18 and the upper and lower sliding plates 6 are connected flexibly, the screw 15 fixes the punch 13 on the body 16, the body 16 is welded on the chassis 17, the upper and lower connecting plates 18 are hinged with the punch 13 through the main shaft 19 and the main shaft bushing 14, The c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap