System and method for inkjet printing with a differential halftoned protective overcoat with gloss compensation

A halftone, inkjet technology, applied in printing, inking devices, typewriters, etc., can solve problems such as increasing printing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

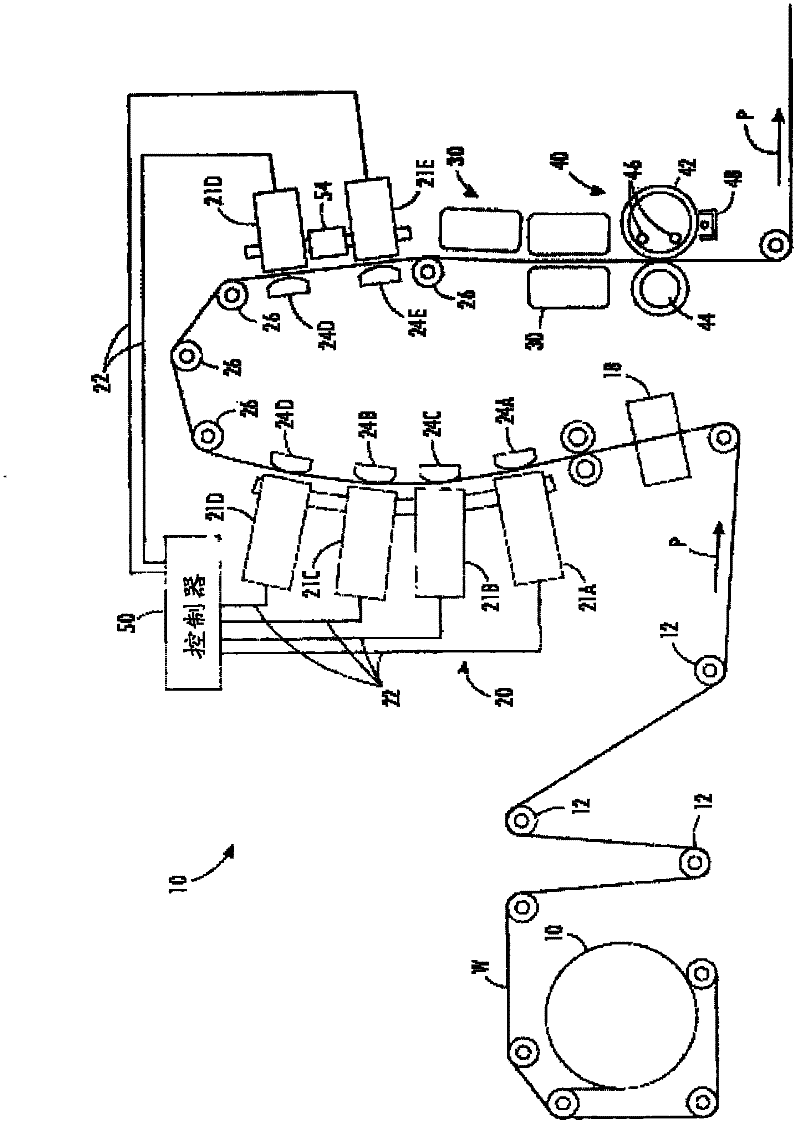

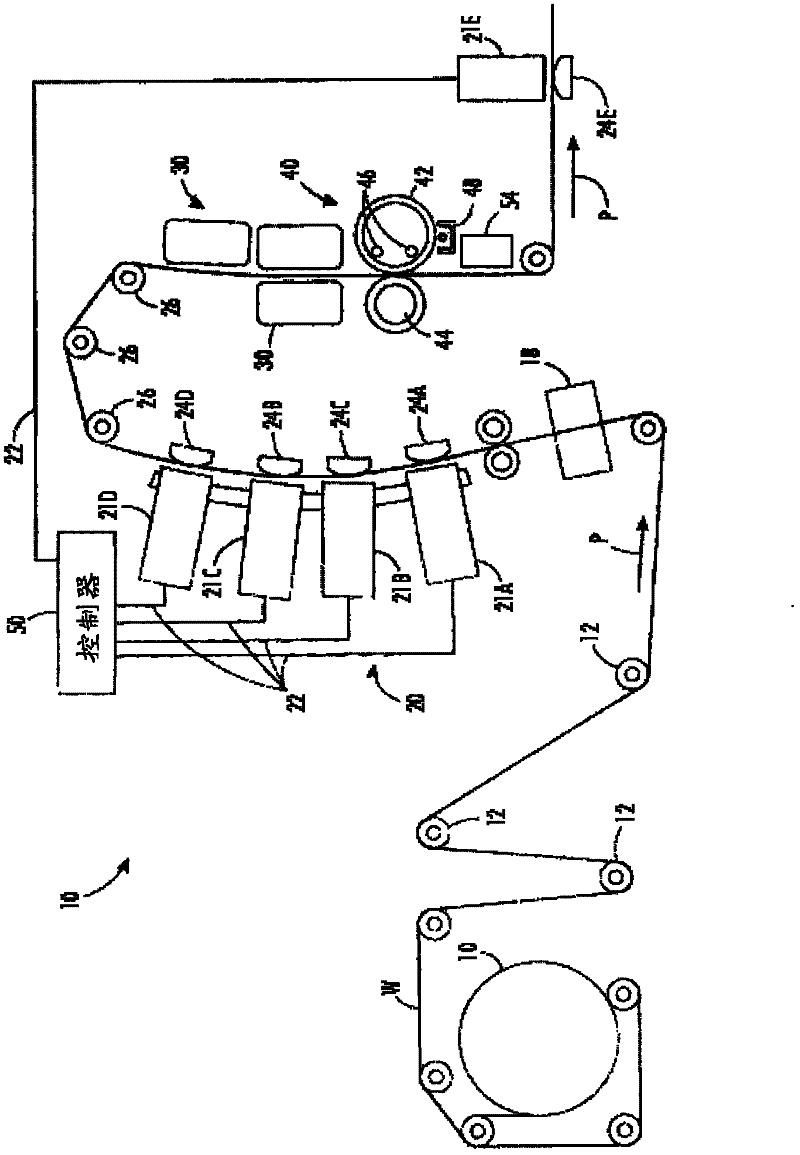

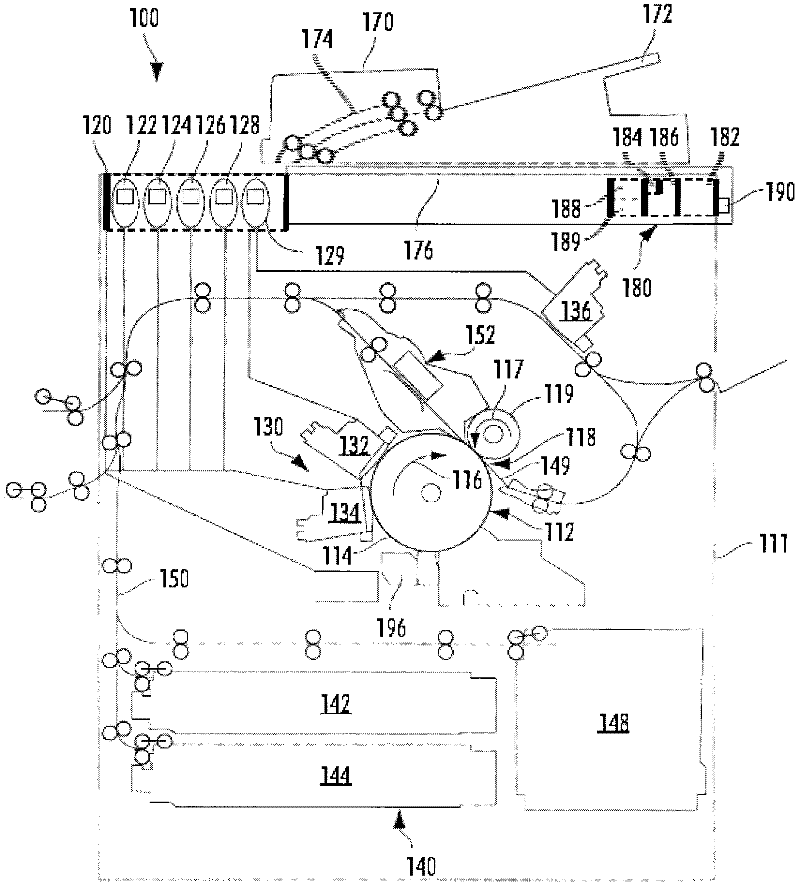

[0017] For a general understanding of the context of the systems and methods disclosed herein, as well as details of the systems and methods, reference is made to the accompanying drawings. In the drawings, the same reference numerals are used to refer to the same elements throughout. As used herein, the term "halftone" refers to the application of ink on a print medium in a patterned manner, wherein the ink partially covers the areas on the print medium where the ink is applied. The halftone level refers to the fraction or percentage of the surface of the printed area that is ink coated. For example, printing ink at a halftone level of 50% coats half of the target surface area of the image receiver with ink, while the remaining 50% remains uncoated. 100% halftone is equivalent to solidly coating a target area of the media surface with ink, while 0% halftone does not apply any ink to a given target area. As used herein, the term "gloss level" refers to the degree to whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com