Method and apparatus for automatic glue level control

A horizontal surface, hot glue technology, applied in the field of book binding devices, can solve the problem of performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

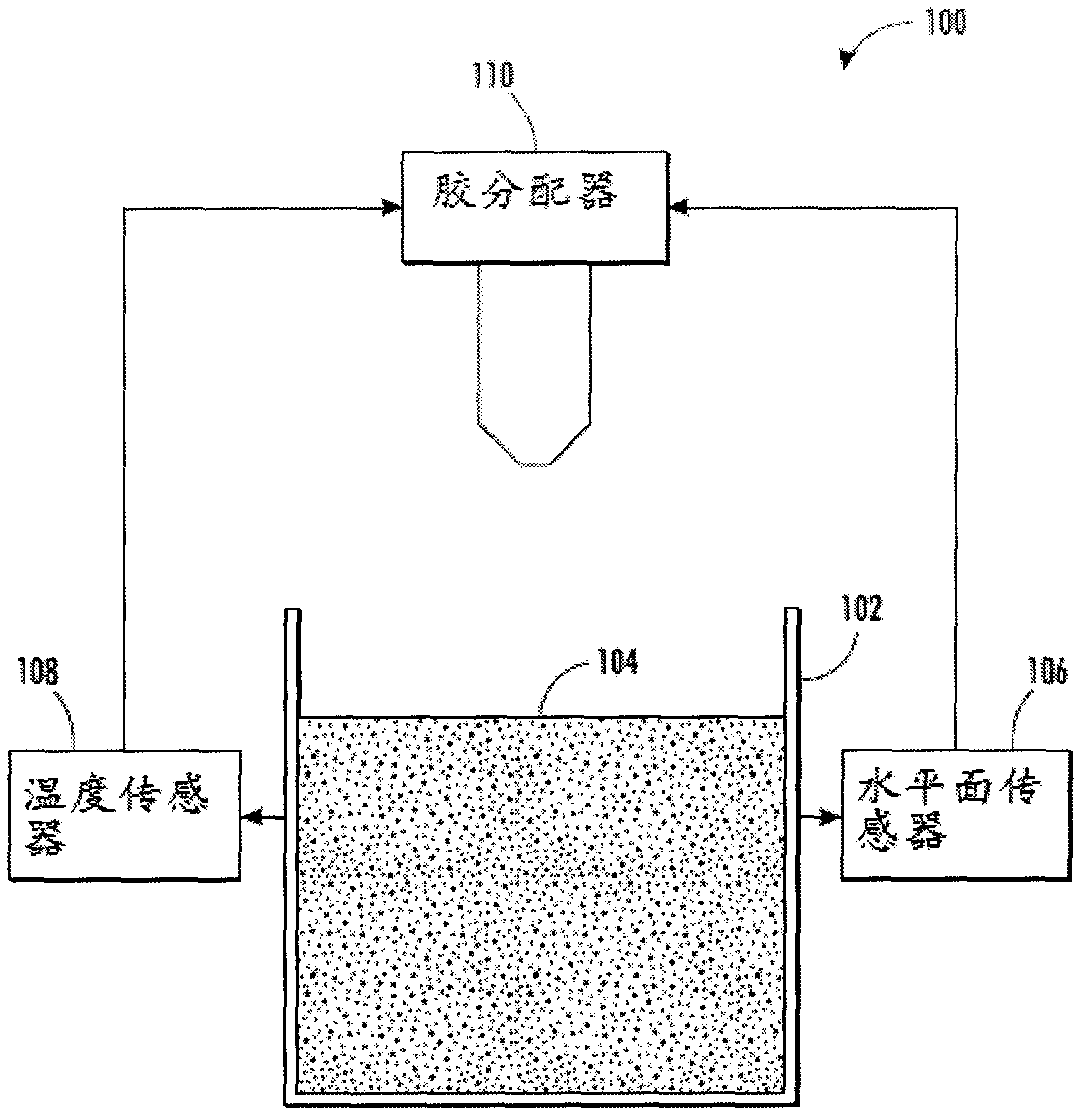

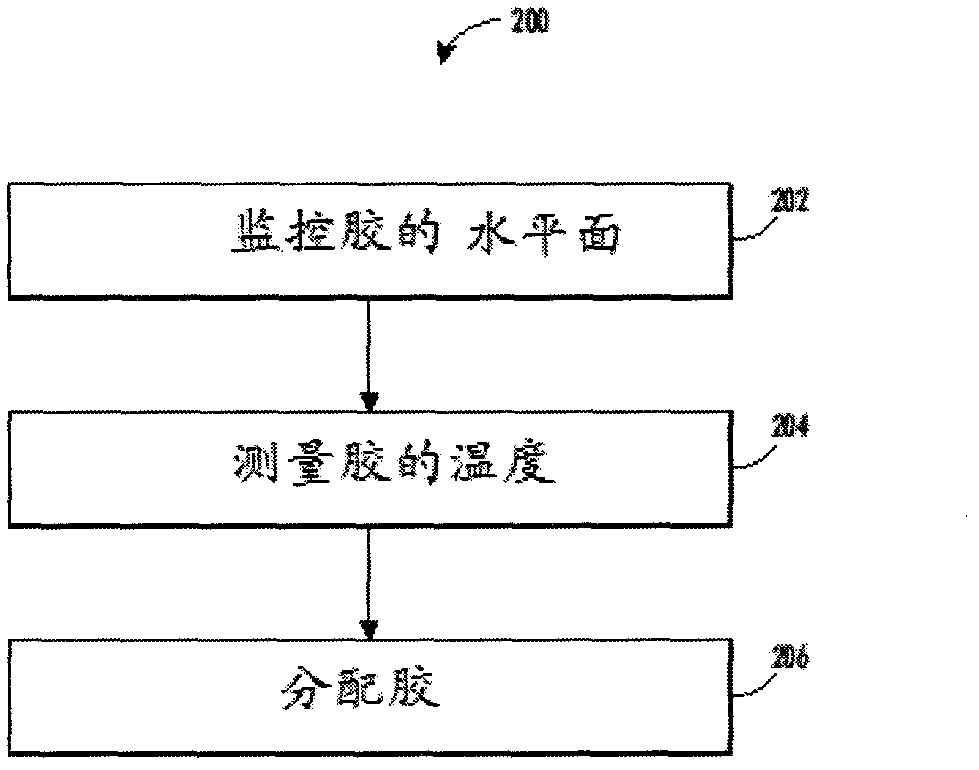

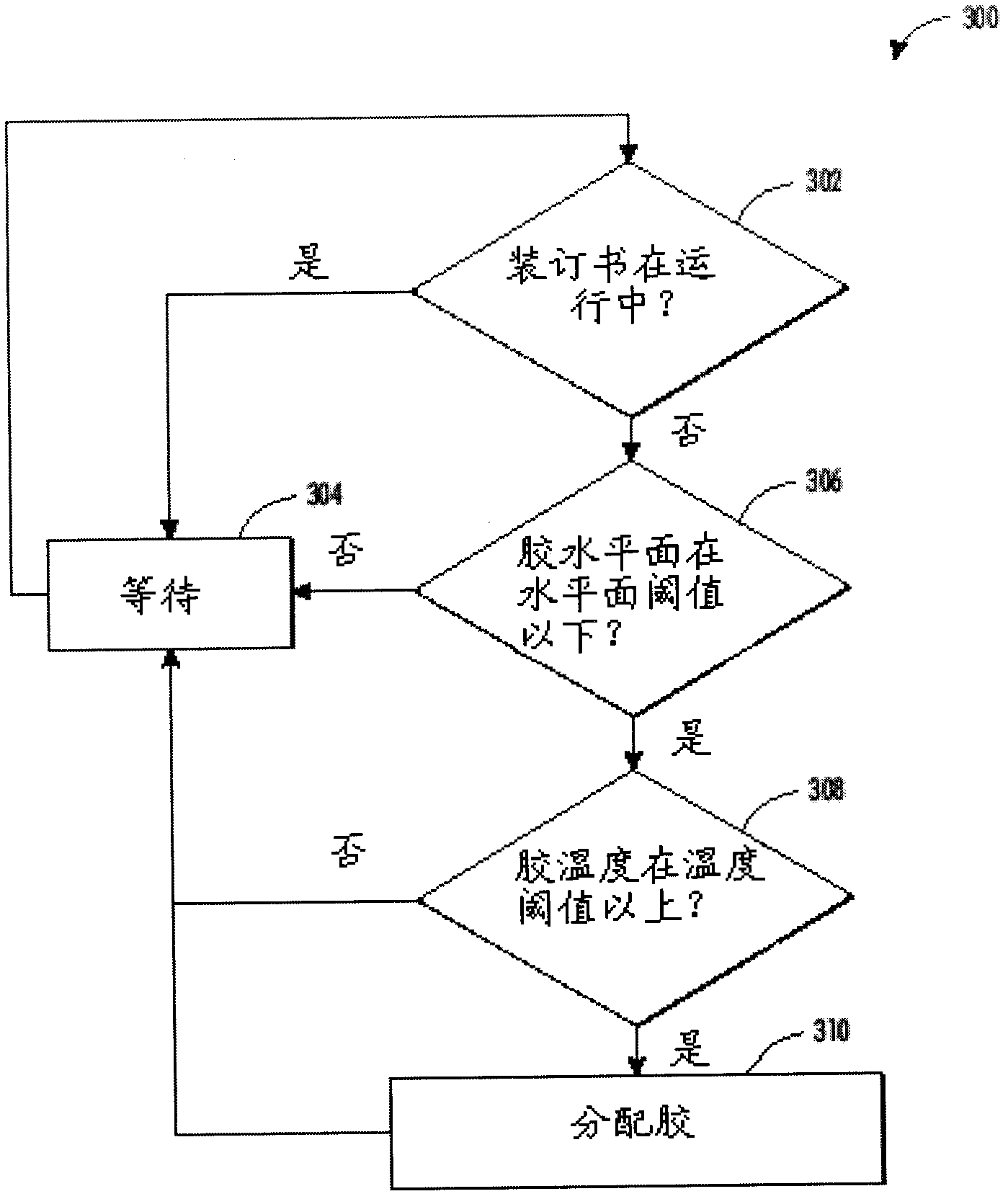

[0010] The present disclosure describes embodiments of an automatic glue dispenser control system and method for a hot glue book binding machine. Certain embodiments of the present disclosure utilize electronic level sensors and temperature sensors to monitor hot glue containers. The control system then dispenses the optimum amount of glue at the selected time to maintain a constant water level and proper operating temperature. Although the disclosed embodiments of the present invention are described with reference to a bound book, it should be understood that the description of the present invention is applicable to any kind of dispensing device, such as a device for dispensing solid ink blobs.

[0011] figure 1 An example system 100 is shown for automatically controlling the level of hot glue in a bookbinding apparatus. System 100 includes container 102 containing glue 104 . Level sensor 106 monitors the level of glue 104 in container 102 and temperature sensor 108 measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com