Submerged arc slag for refining aluminum-containing low-silicon steel ladle and preparation method for submerged arc slag

A technology for ladle refining and submerged arc slag is applied in the field of submerged arc slag, submerged arc slag for refining aluminum-containing low-silicon steel ladle and its preparation, and can solve the problems of high cost, large addition amount, and unfavorable accurate control of aluminum-containing steel, etc. Achieve low cost, prolong furnace lining life, and ensure the effect of molten steel refining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

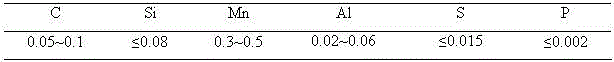

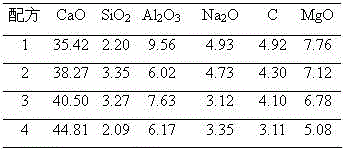

[0030] The submerged arc slag used for refining the aluminum-containing low-silicon steel ladle of the present invention has a chemical composition weight percentage satisfying: 35%2 o 3 2 O2 <5%, 3%<C<5%, and the rest are impurities.

[0031] The chemical composition of the submerged arc slag CaO, Al 2 o 3 , MgO, Na 2 O, SiO 2 And C are jointly provided by six raw materials of limestone, dolomite, soda ash, high alumina bauxite, coke and cement clinker.

[0032] The respective chemical composition weight percentages of the six kinds of raw materials meet respectively:

[0033] Limestone: 53%2 <6.0%, S<0.1%;

[0034] Dolomite: 15%2 <5.0%;

[0035] Soda ash: Na 2 CO 3 >95%;

[0036] High alumina vanadium: Al 2 o 3 >75%, SiO 2 <8%;

[0037] Coke: C>90%;

[0038] Cement clinker: 62%2 2 o 3 <7%.

[0039] The method for preparing submerged arc slag of the present invention comprises the following steps:

[0040] 1) Detect the chemical composition content of raw mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com