End plate, and rotor for rotary electric machine which employs the end plate

A technology of rotating electrical machines and end plates, which is applied in the directions of electromechanical devices, electrical components, and electric components, etc., can solve the problem of increasing eddy current loss, and achieve the effect of suppressing eddy current loss and short circuit of magnetic flux through the end plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings. In the following description, the specific shapes, materials, values, directions, etc. are only illustrations to facilitate the understanding of the present invention, and can be changed as appropriate according to the application, purpose, specific requirements, etc.

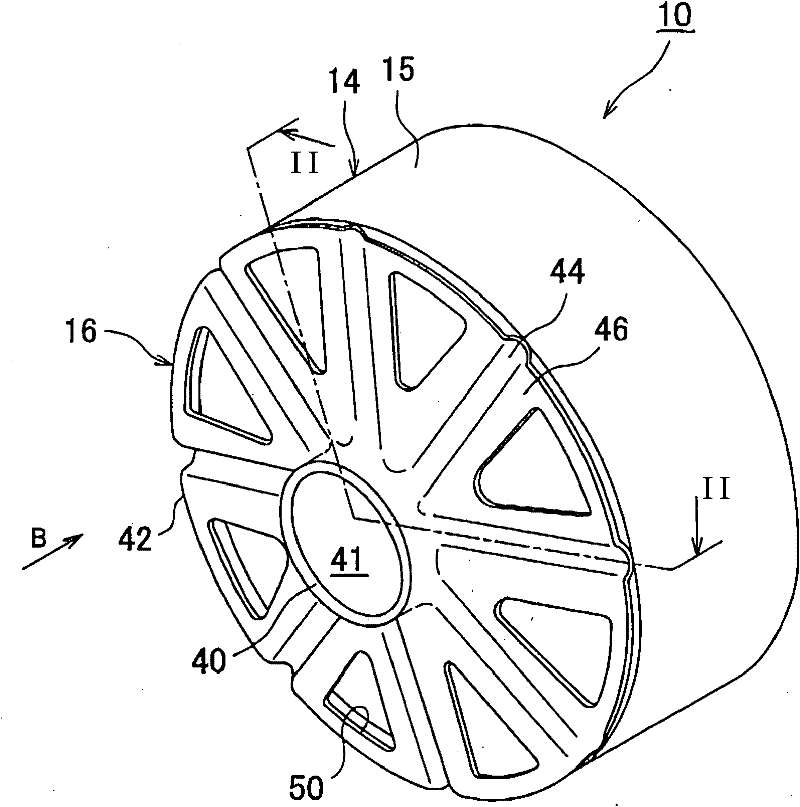

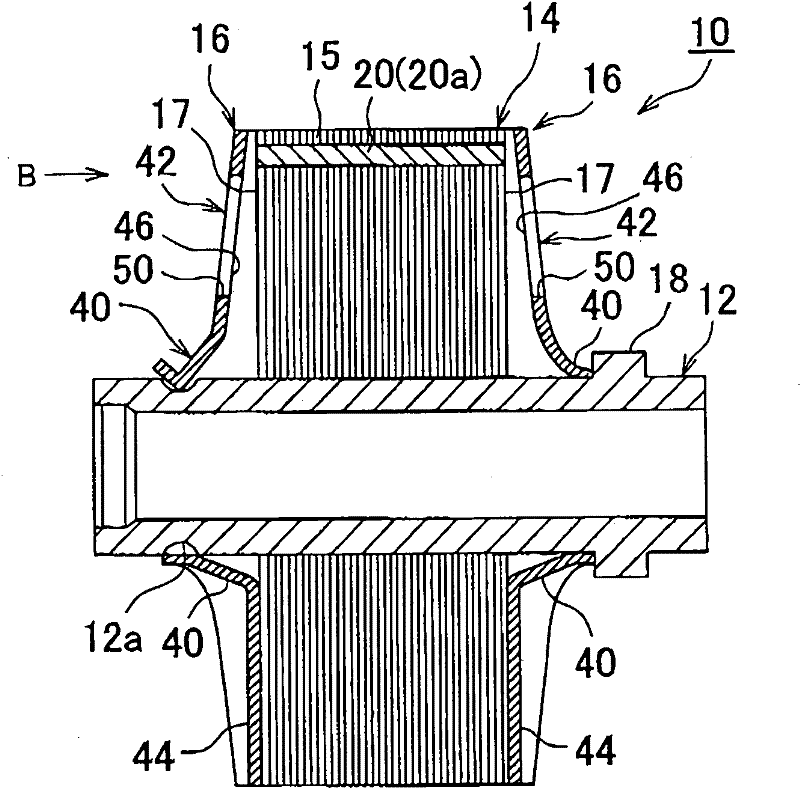

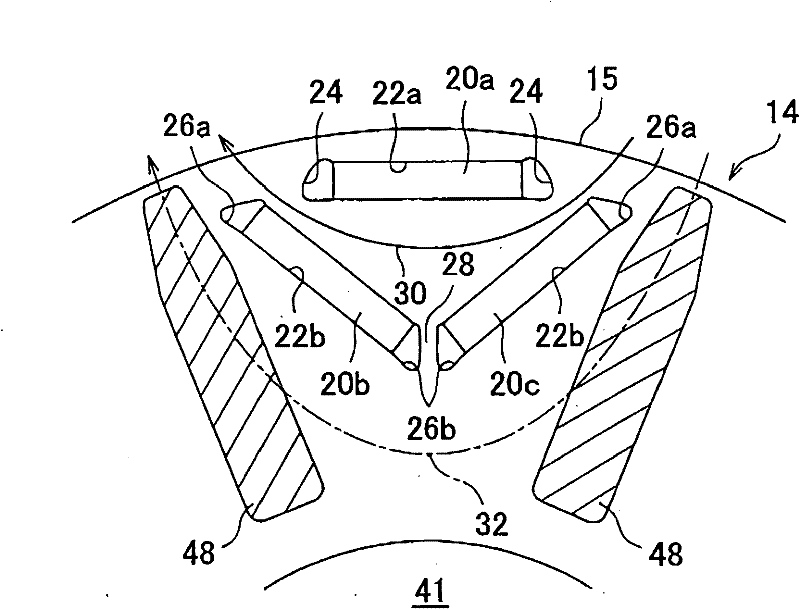

[0025] figure 1 is a perspective view showing a rotor 10 for a rotary electric machine including an end plate 16 of an embodiment of the present invention omitting a diagram of a rotor shaft. figure 1 Only the end plate 16 provided on one of the sides of the rotor 10 in the axial direction of the rotor 10 is shown. also, figure 2 is a sectional view of the rotor 10 including a diagram of the rotor shaft 12 and taken along the axial direction of the rotor 10 . In the following description, the direction along the rotation center axis of the rotor shaft 12 is referred to as the "ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com