Interior magnet rotary electric machine

A technology of rotating electrical machines and magnets, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuits, etc. Achieve high-speed rotation efficiency, suppress eddy current loss, and improve strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0028] (Structure of IPM motor)

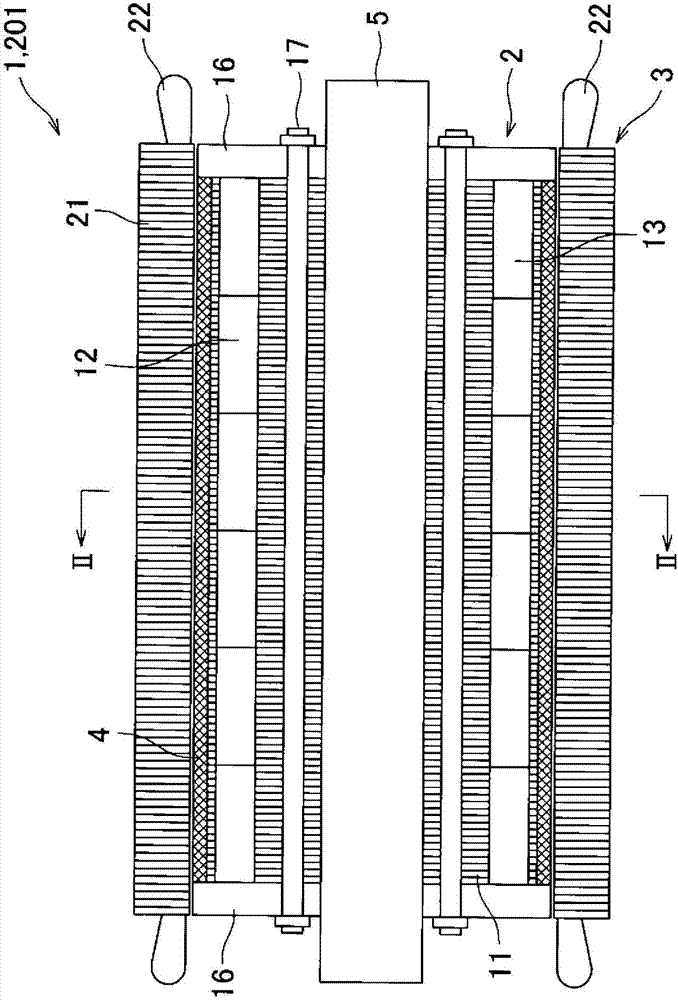

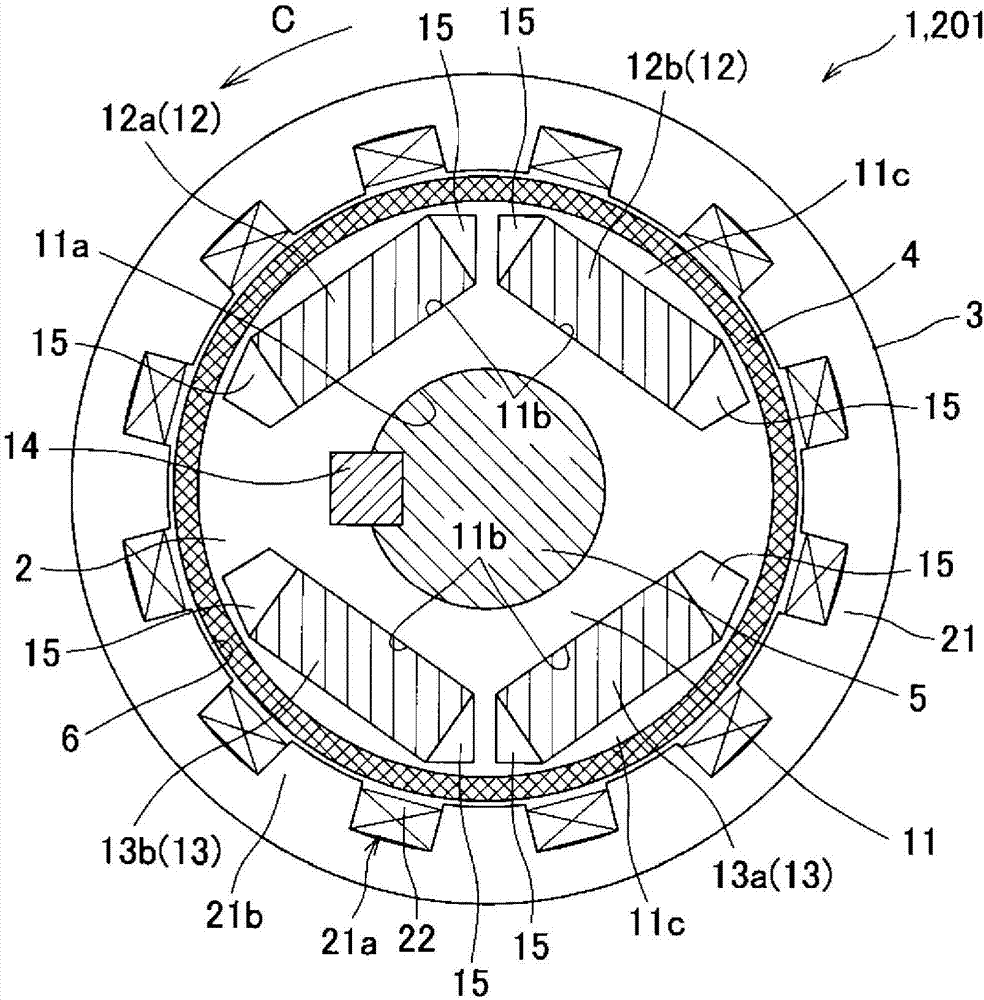

[0029] A magnet-embedded rotating electrical machine according to a first embodiment of the present invention is an IPM motor. as a sectional view figure 1 and as figure 1 Line II-II sectional view of figure 2 As shown, the IPM motor 1 has a rotor (rotator) 2 and a cylindrical stator (fixer) 3 arranged to face the rotor 2 on the radially outer side of the rotor 2 . The rotor 2 is disposed within the stator 3 so that its axis coincides with that of the stator 3 (coaxially). In addition, the rotor 2 and the stator 3 are housed in an unillustrated case.

[0030] (rotor)

[0031] The rotor 2 has a cylindrical rotor core 11 and two sets of permanent magnets 12 and 13 embedded in the rotor core 11 . Rotor 2 is able to figure 2 The C direction shown and its opposite direction of rotation.

[0032] The rotor core 11 is formed, for example, by laminating annular plate-shaped electrical steel sheets (35H300 or the like) in the axial direction....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com