Trigger power supply capable of following temperature characteristic of thyristor

A technology of thyristor temperature and trigger power supply, which is applied in the field of thyristor trigger power supply, power supply, bidirectional thyristor trigger power supply, can solve the problems of large trigger current, waste of energy, waste of energy reliability, etc. Heat, Trigger Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

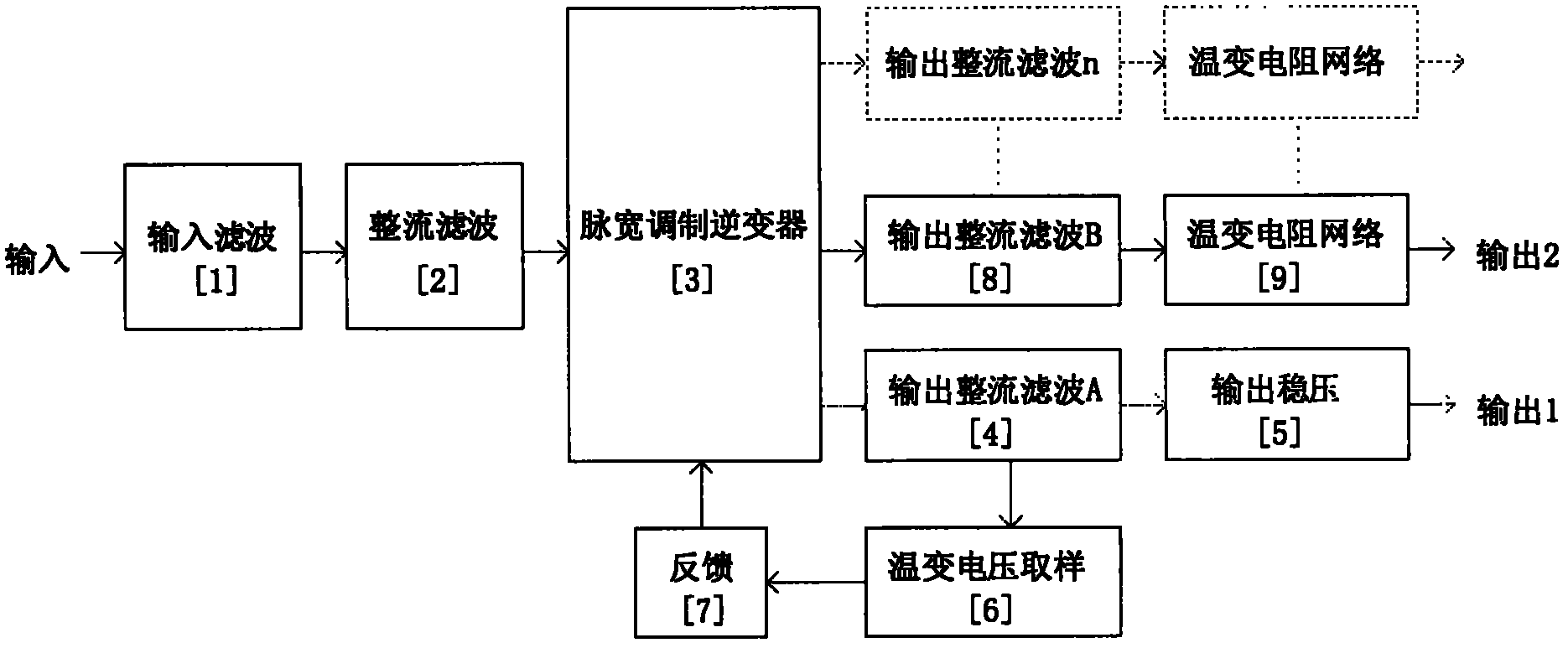

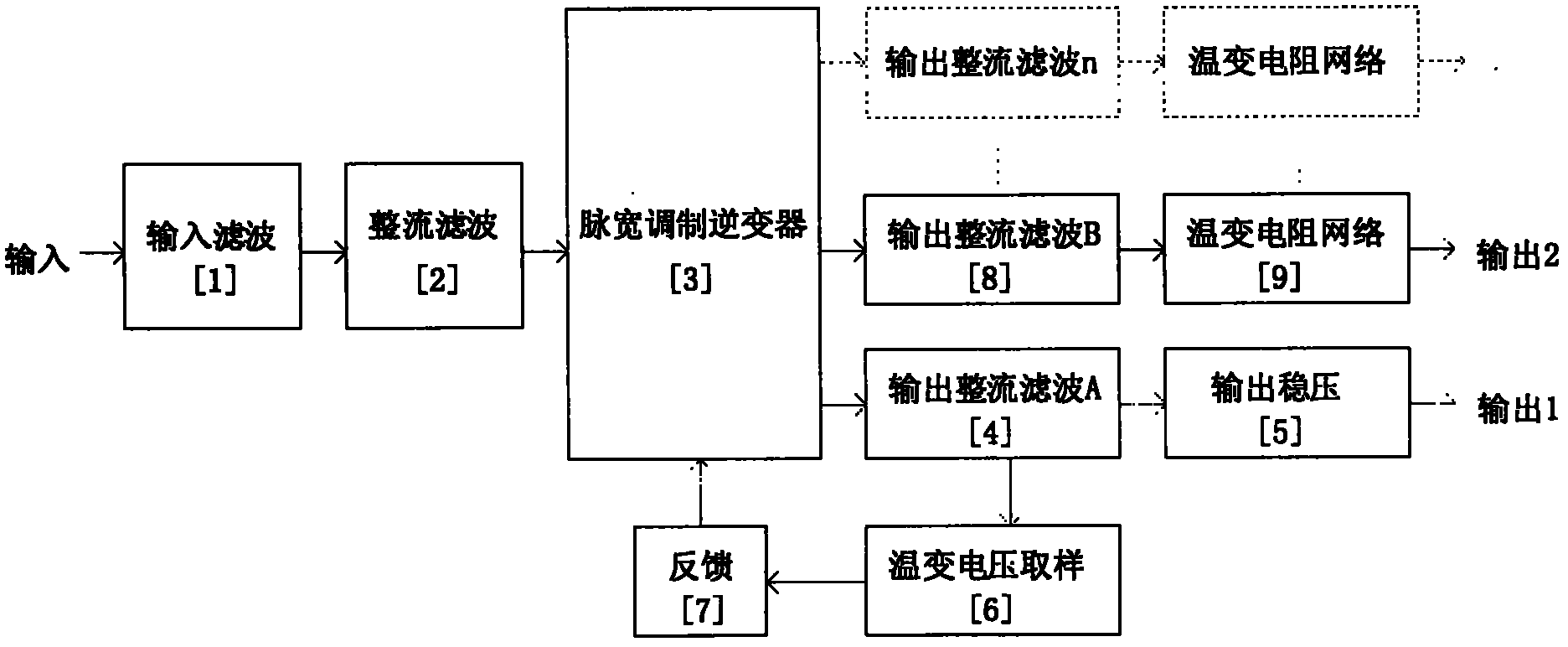

[0025] see figure 1 , the AC power enters the pulse width modulation inverter [3] through the input filter [1], the rectification filter [2], the inverter output through the output rectification filter A [4], the output voltage stabilization [5] to output a stable DC voltage supply The external control circuit is used; the inverter output becomes the trigger power supply through the output rectification filter B[8], and then provides the trigger current for the external thyristor through the temperature variable resistance network [9]; the temperature variable voltage sampling [6] is used for the output rectification filter A [4] performs voltage sampling, and provides a feedback signal to the pulse width modulation inverter [3] through feedback [7] to keep the output voltage of the inverter stable at a stable temperature.

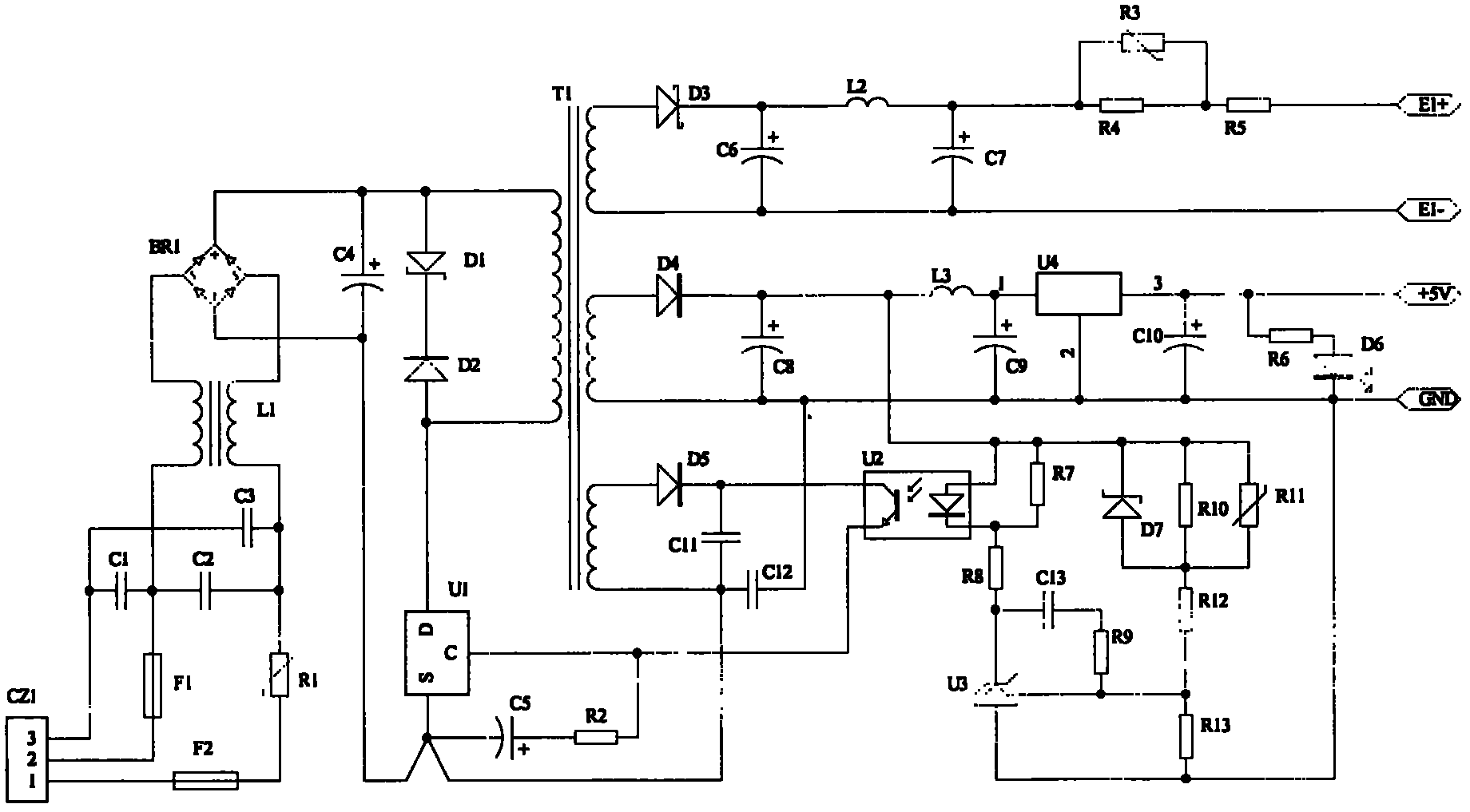

[0026] see figure 2 , is an improved single-ended flyback switching power supply, CZ1 is the AC power input socket, F1 and F2 are fuse tubes, and R1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com