Printed circuit board with combined type via holes

A printed circuit board, composite technology, applied in the direction of printed circuit components, electrical connection printed components, etc., can solve the problem of signal quality, affect the overall system execution efficiency and other problems, and achieve the effect of reducing impedance discontinuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Below in conjunction with accompanying drawing and preferred embodiment the present invention is described in further detail:

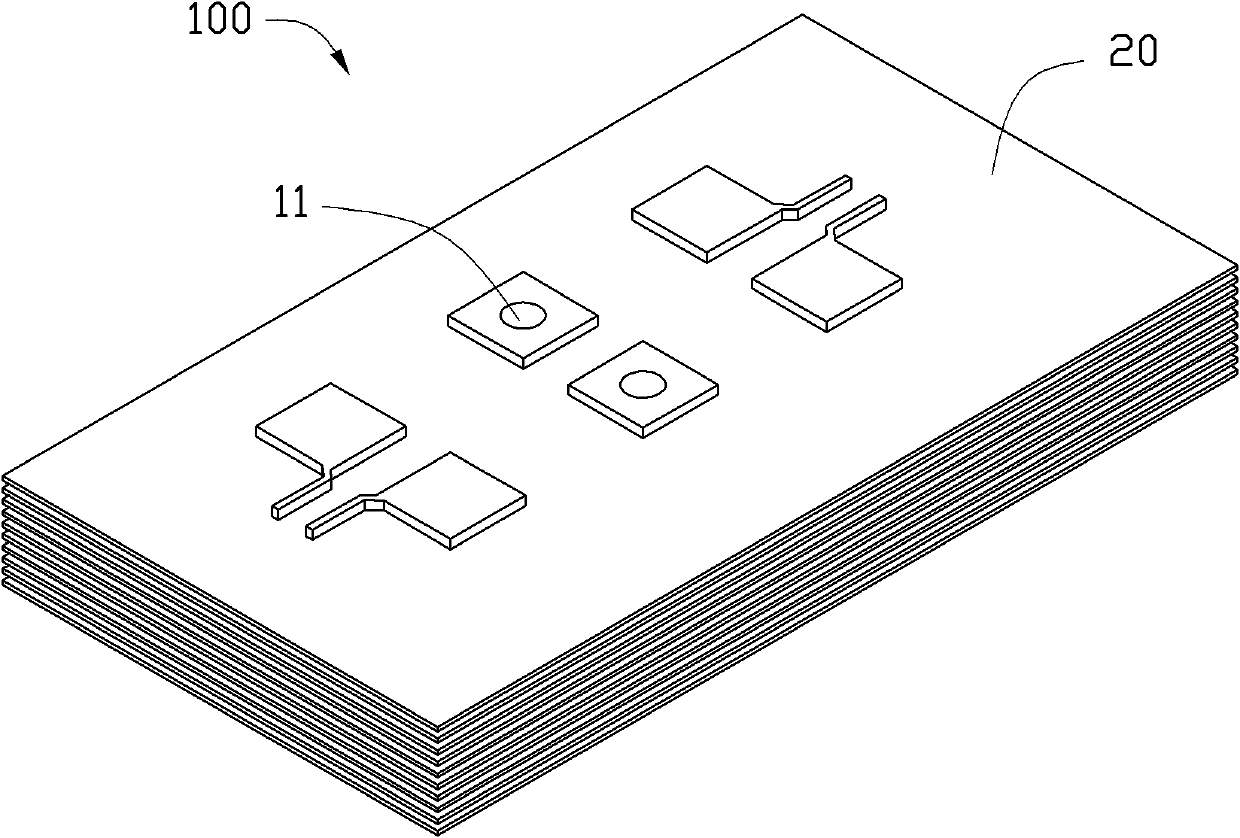

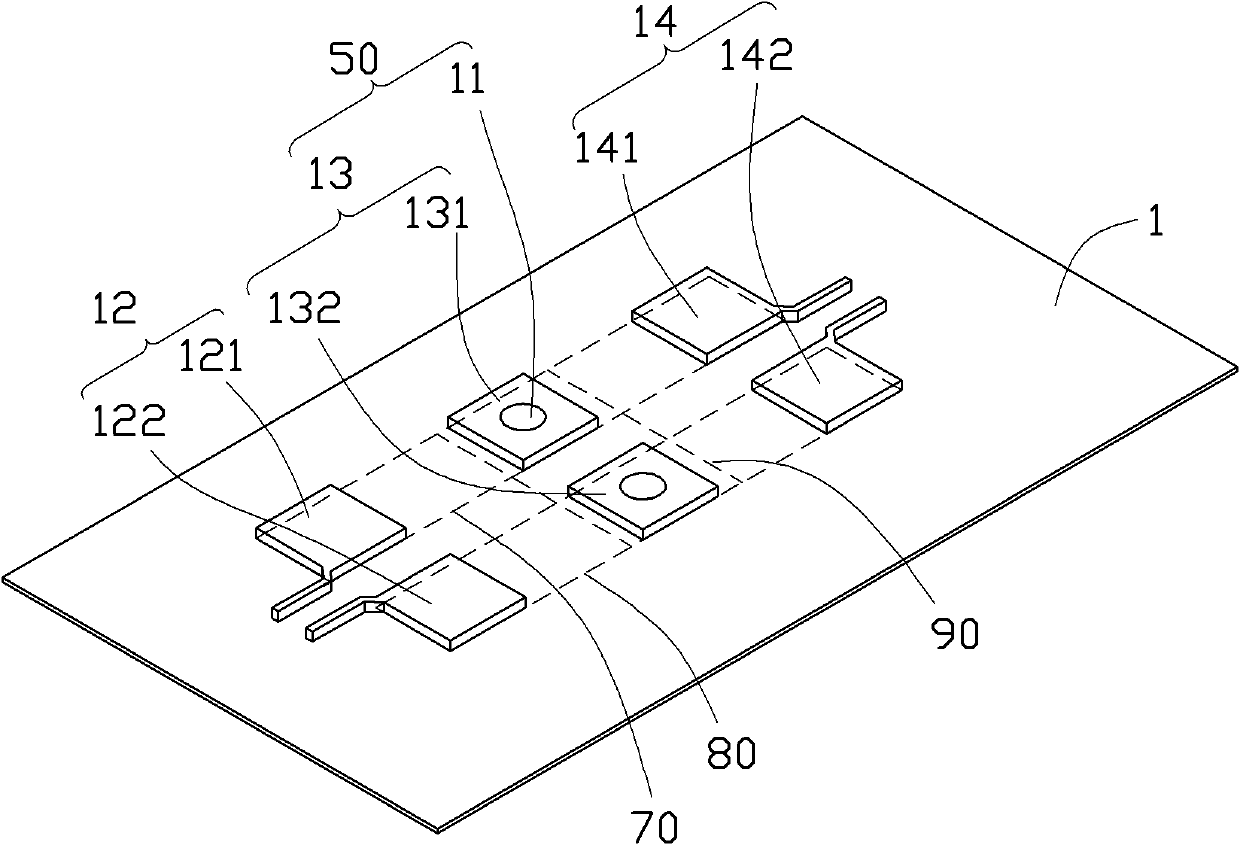

[0059] see Figure 1 to Figure 6 , the printed circuit board 100 provided with composite via holes in the present invention includes a board body 20 and a through hole 11 penetrating through each layer of the board body 20 . In this embodiment, the board body 10 is a 10-layer board body, the first layer 1, the third layer, the eighth layer and the tenth layer 10 are signal layers; the second layer 2, the fourth layer 4, the fifth layer Layer 9, sixth layer, seventh layer and ninth layer 9 are reference layers. The top of the through hole 11 is located on the first layer. The bottom of the through hole 11 is located at the tenth layer.

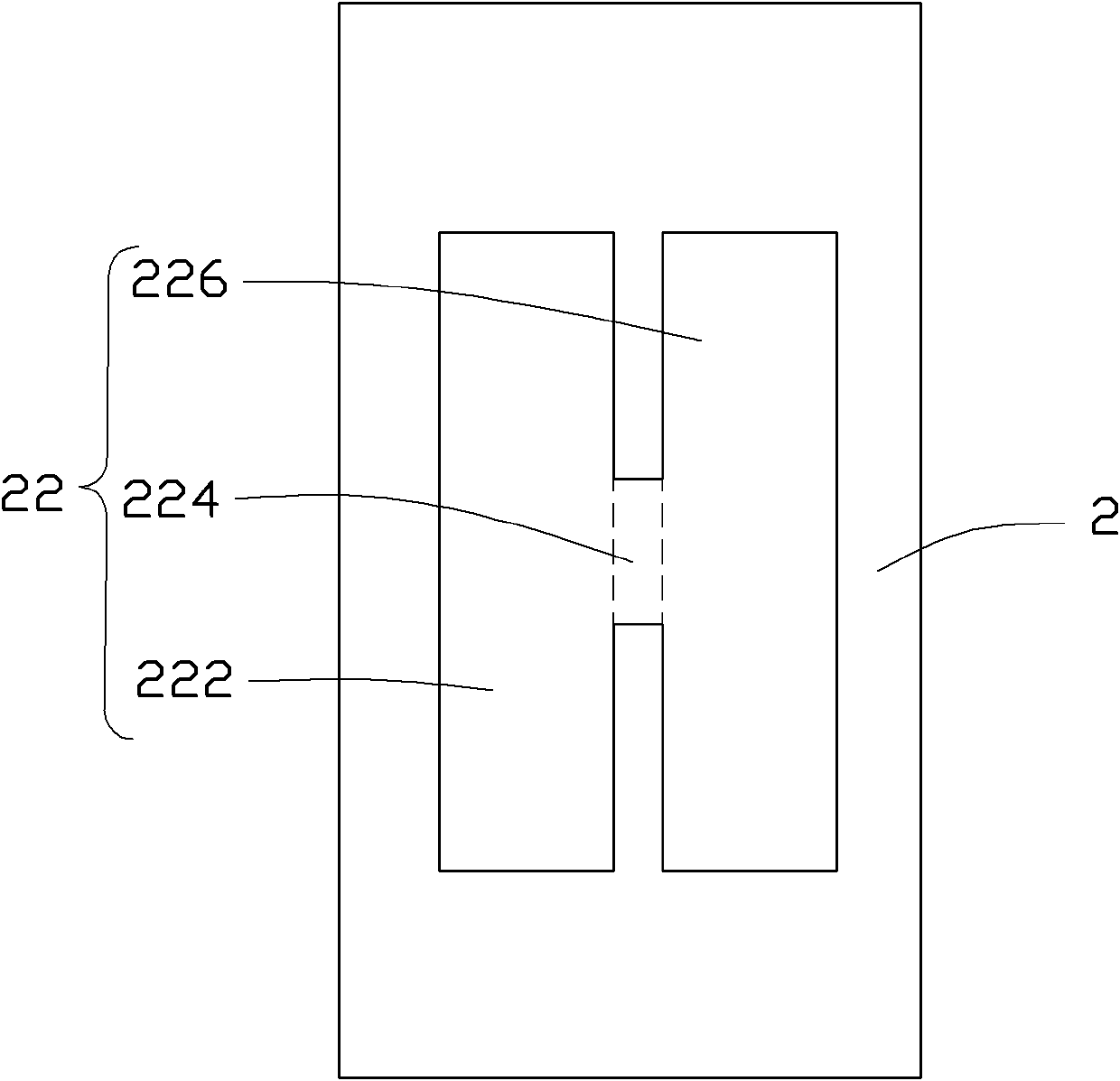

[0060] Please continue to refer figure 2 and image 3, first to third pairs of pads 12-14 are arranged on the first layer 1. Tops of the through holes 11 penetrate through the second pair of pads 13 . Wh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap