Translational motion type irrigation machine

An irrigation machine and translational technology, applied in the field of irrigation machines, can solve the problems of limited water storage in the water storage tank, failure to achieve full irrigation, and limited liquid storage in the liquid supply device, so as to achieve uniform irrigation, water saving, and sufficient water supply Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

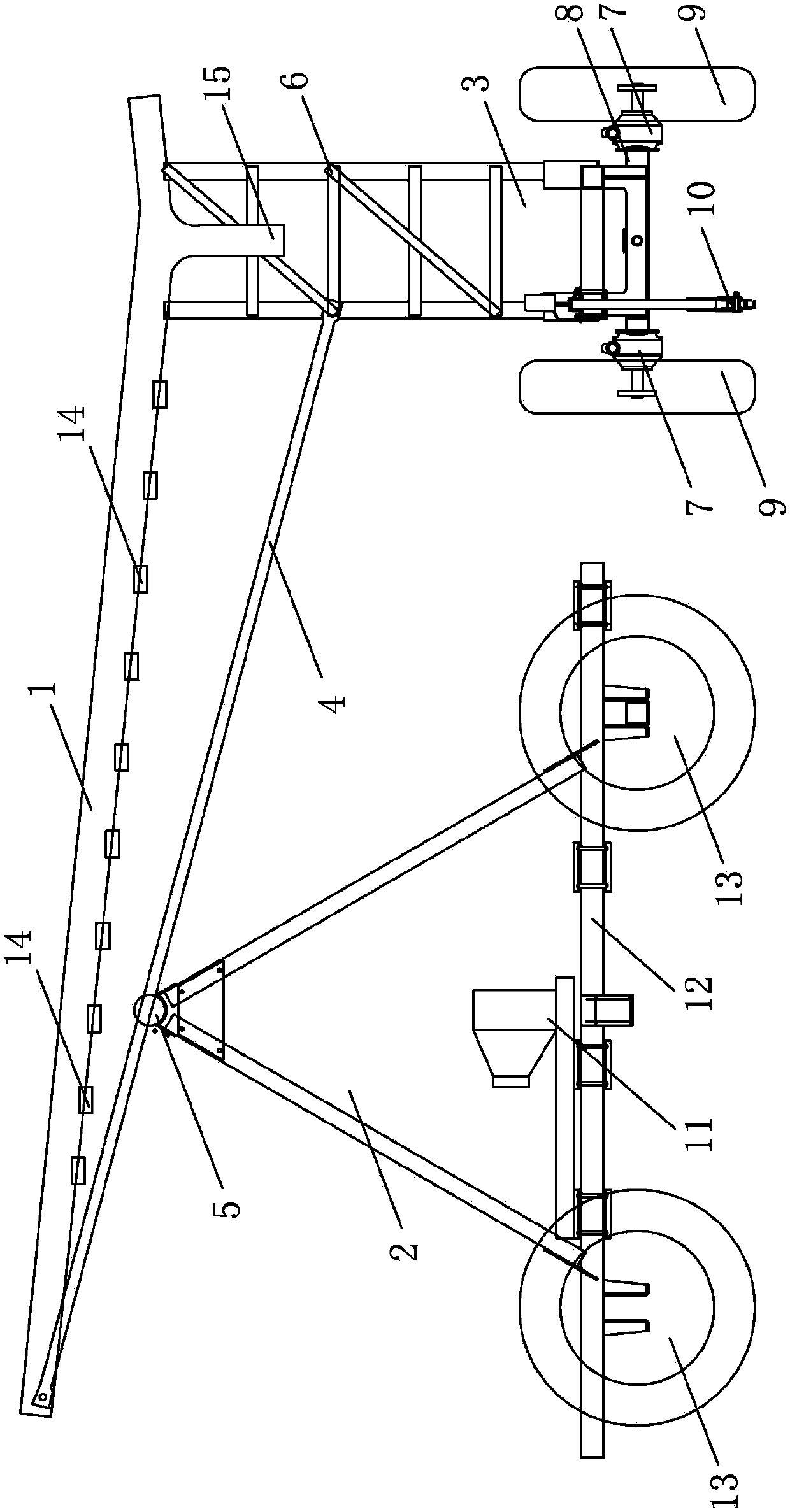

[0027] Embodiment 1 of a kind of translation irrigation machine of the present invention, as figure 1 As shown, it includes a control system, a water spray pipeline 1, a translation mechanism 2, and a water supply mechanism 3 that can translate and rotate. The water spray pipeline 1 is arranged above the translation mechanism 2. 3 is connected by a lever 4, and the fulcrum 5 of the lever 4 is connected with the translation mechanism 2. Since the translation mechanism 2 and the water supply mechanism 3 capable of translation and rotation are provided, the present invention has no irrigation dead angle during irrigation and can achieve comprehensive irrigation, and the present invention can irrigate evenly, thereby saving water sources.

[0028] Wherein, one end of the lever 4 is movably connected to the water spray pipe 1, and the other end of the lever 4 is fixedly connected to the supporting device 6 of the water supply mechanism 3, and the lever 4 and the fulcrum 5 are movab...

Embodiment 2

[0037] Embodiment 2 of a translational irrigation machine of the present invention is different from Embodiment 1 in that the water pipe joint 10 is connected with the water spray pipe 1 as a whole. Other structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

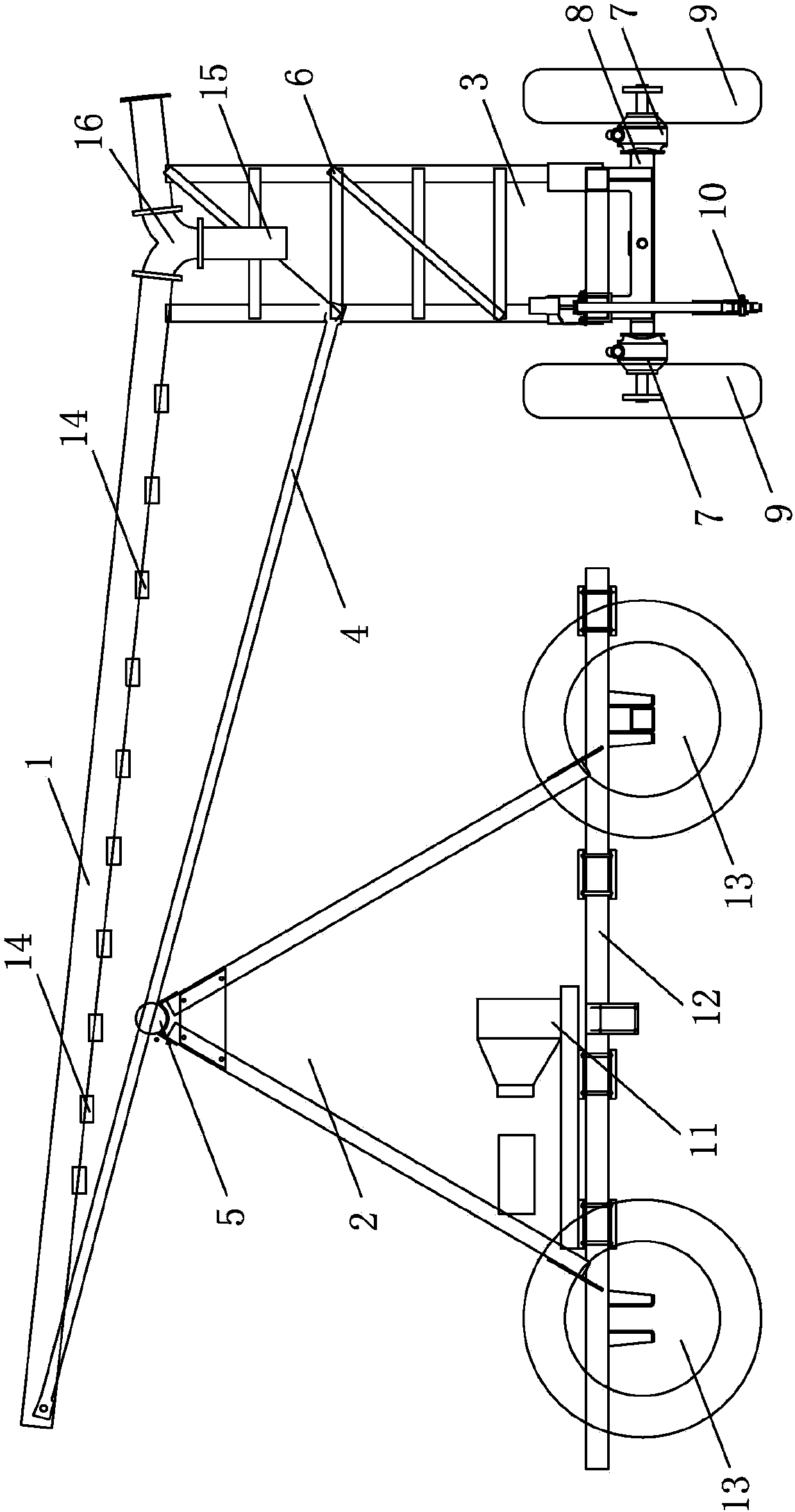

[0039] Embodiment 3 of a translation irrigation machine of the present invention, as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the nozzle at one end of the water spray pipeline 1 is connected with a three-way pipe 16, and the lower end nozzle of the three-way pipe 16 is communicated with the water pipe joint 10 through a section of water pipe, and the three-way Another nozzle of the pipe 16 is connected with a second water spray pipeline, and the second water spray pipeline is connected with a second water supply mechanism. Other structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com