Integrated bending forming device for abnormally-shaped tube

A technology for bending and forming special-shaped tubes, applied in the field of cab structure, can solve the problems of poor control of forming springback, different bending springback rates of special-shaped tubes, and the change of springback size cannot be calculated by data, etc., and achieves practicability. Strong and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

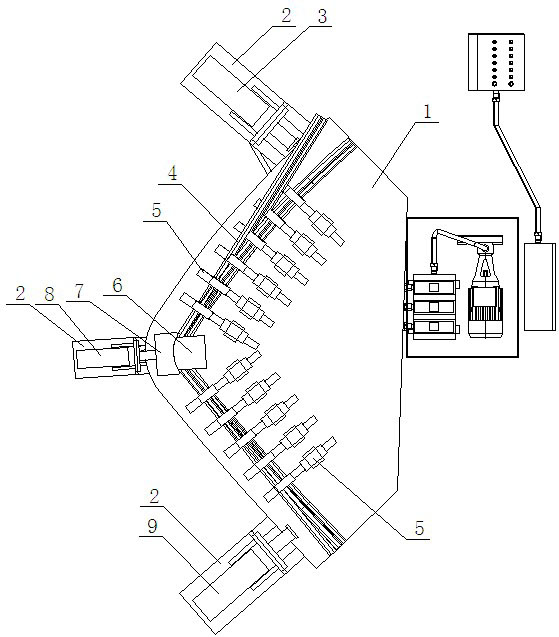

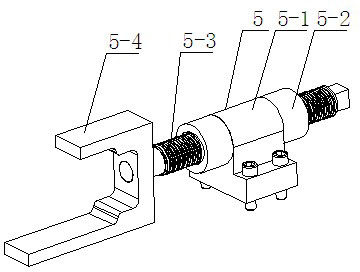

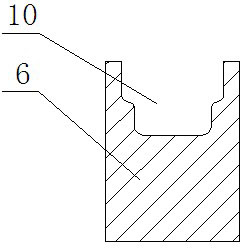

[0012] like figure 1 As shown, the overall bending and forming device for the special-shaped pipe includes a working platform 1, and the outer side of the working platform 1 is connected with three oil cylinder brackets 2, the first oil cylinder bracket 2 is connected with the first hydraulic oil cylinder 3, and the second oil cylinder bracket 2 is connected with the first hydraulic oil cylinder 3. Two hydraulic cylinders 8, a third hydraulic cylinder 9 is connected to the third cylinder support 2, the second hydraulic cylinder 8 is arranged between the first hydraulic cylinder 3 and the third hydraulic cylinder 9, the first hydraulic cylinder 3, the second hydraulic cylinder 9 8 and the telescopic ends of the third hydraulic cylinder 9 face the working platform 1 respectively, the telescopic end of the second hydraulic cylinder 8 is connected to the limit block 7, the other side of the limit block 7 is provided with a positioning block 6, and the positioning block 3 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com