Heart-shaped fixture

A technology of chicken heart clamp and chicken heart clamp, which is applied in the direction of grinding workpiece support, etc., can solve the problems of clamping effect, cumbersome, safety accidents, etc., achieve good clamping effect and ensure safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in conjunction with accompanying drawing.

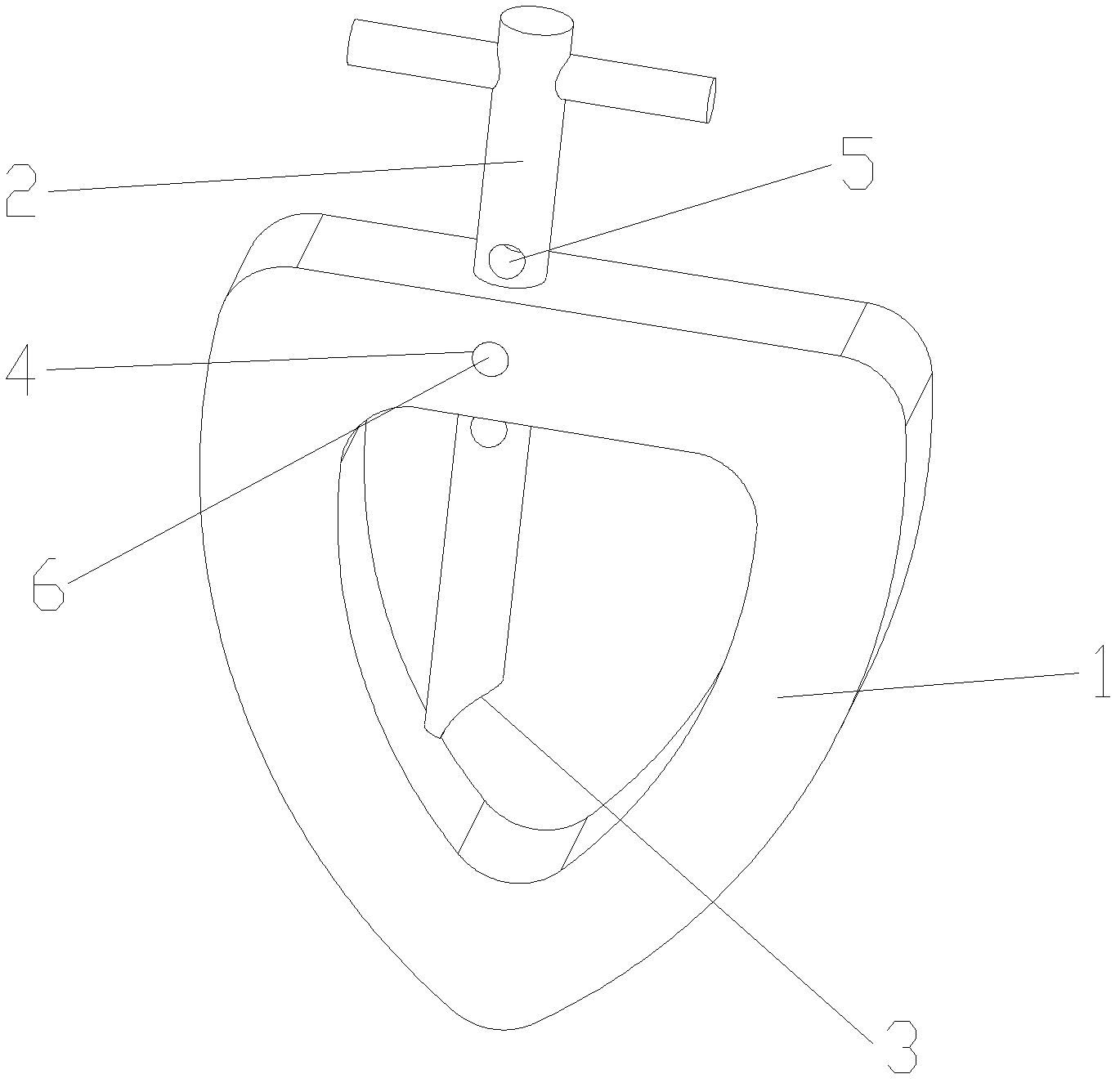

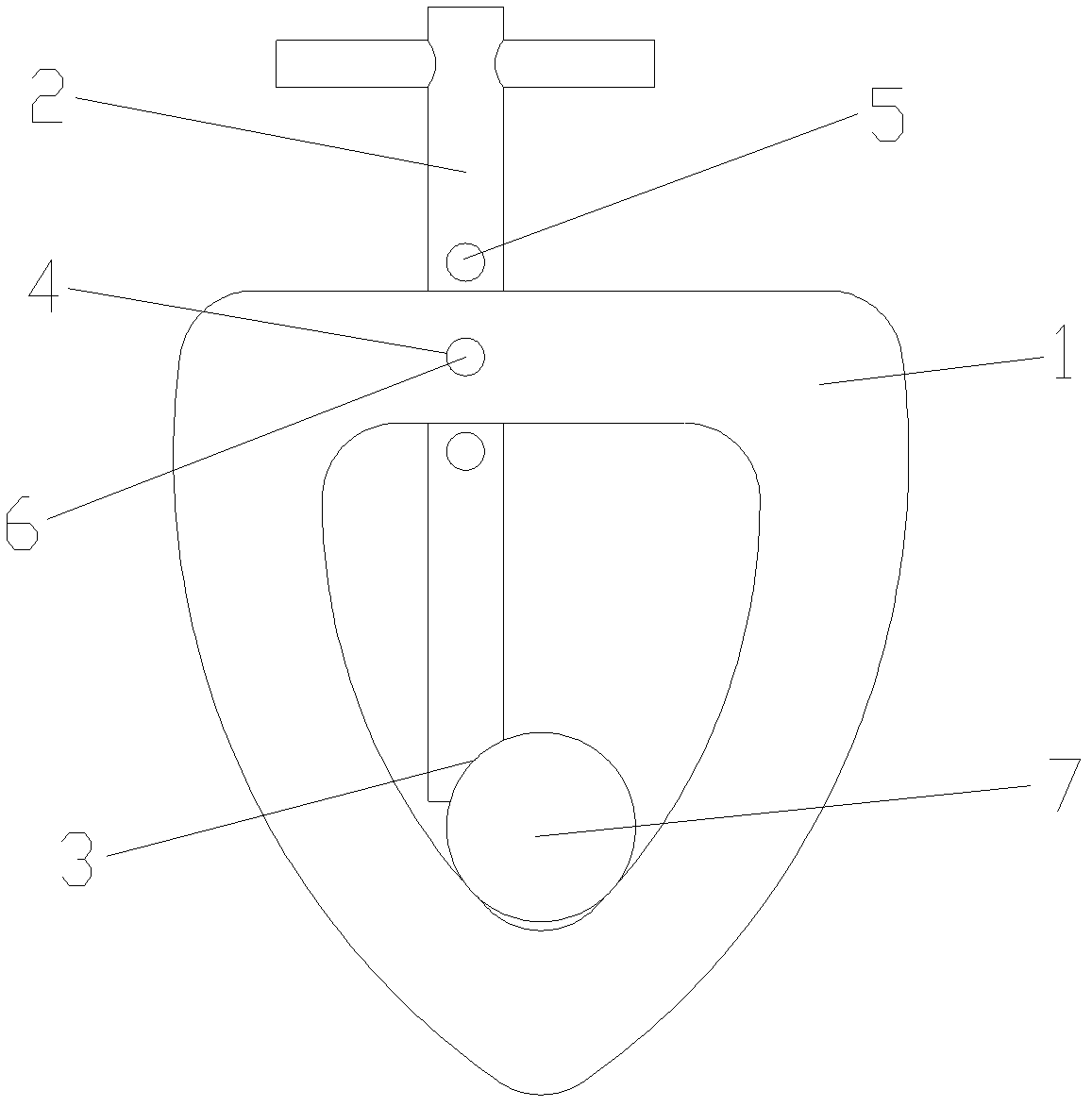

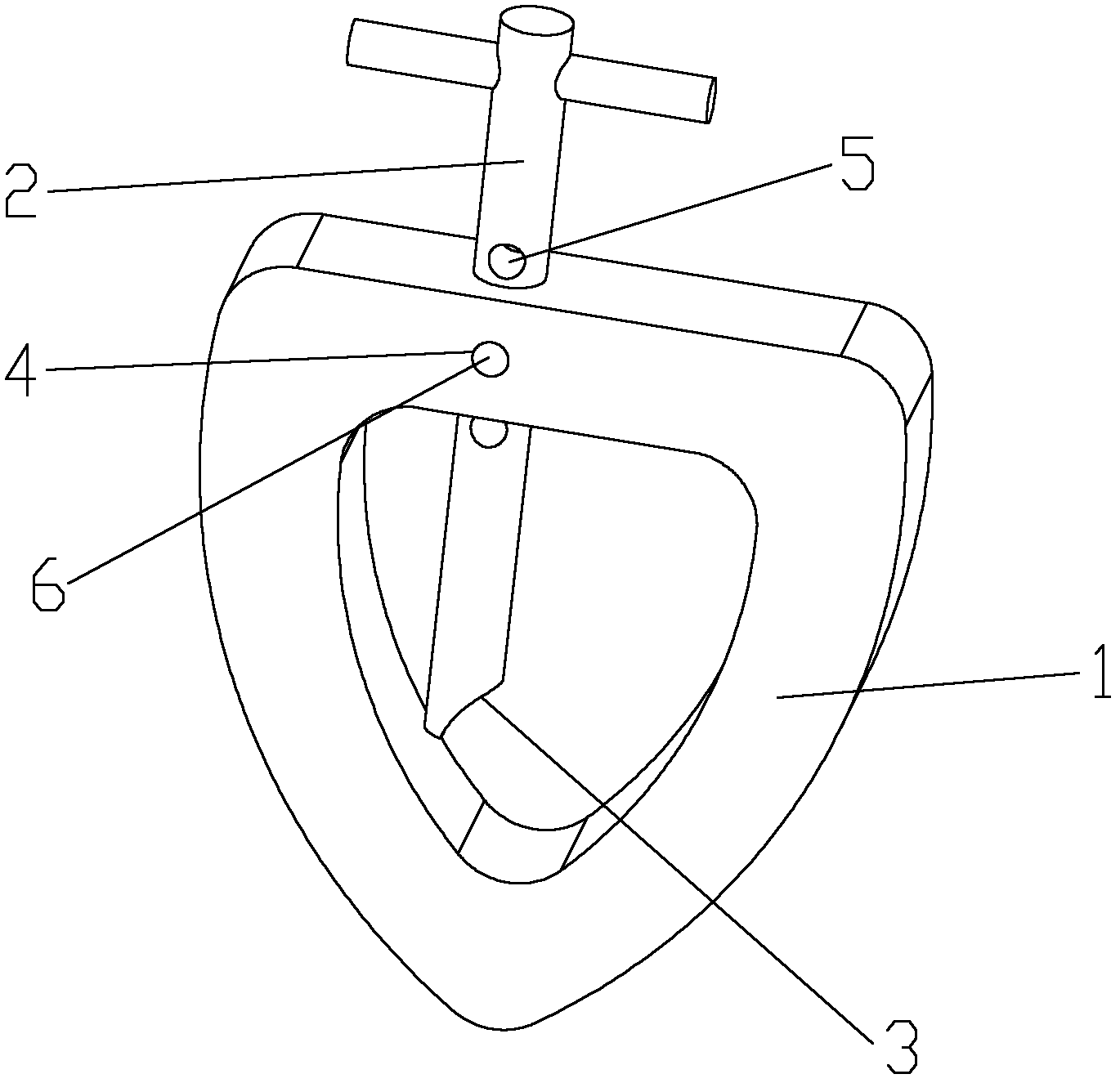

[0015] as attached figure 1 The shown chicken heart clamp according to the present invention includes a chicken heart clamp body 1, and the chicken heart clamp body 1 is provided with a push rod 2 that can slide up and down along the chicken heart clamp body; the push rod 2 is "T" shaped rod; the bottom of the ejector rod 2 is provided with an arc-shaped groove 3; the axis of the ejector rod 2 is parallel to but not collinear with the front center line of the chicken heart sandwich body 1; the first positioning hole is provided on the chicken heart sandwich body 1 4; three second positioning holes 5 are opened on the ejector rod 2; the diameters of the first positioning hole 4 and the second positioning hole 5 are the same; the first positioning hole 4 is aligned with any second positioning hole 5 , the first positioning hole 4 and the second positioning hole 5 are inserted with a pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com