Air conditioner upper cover fixing structure

A fixed structure, air conditioner technology, applied in the directions of heating and ventilation hoods/covers, etc., can solve problems such as deformation, and achieve the effect of preventing gaps and saving labor and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

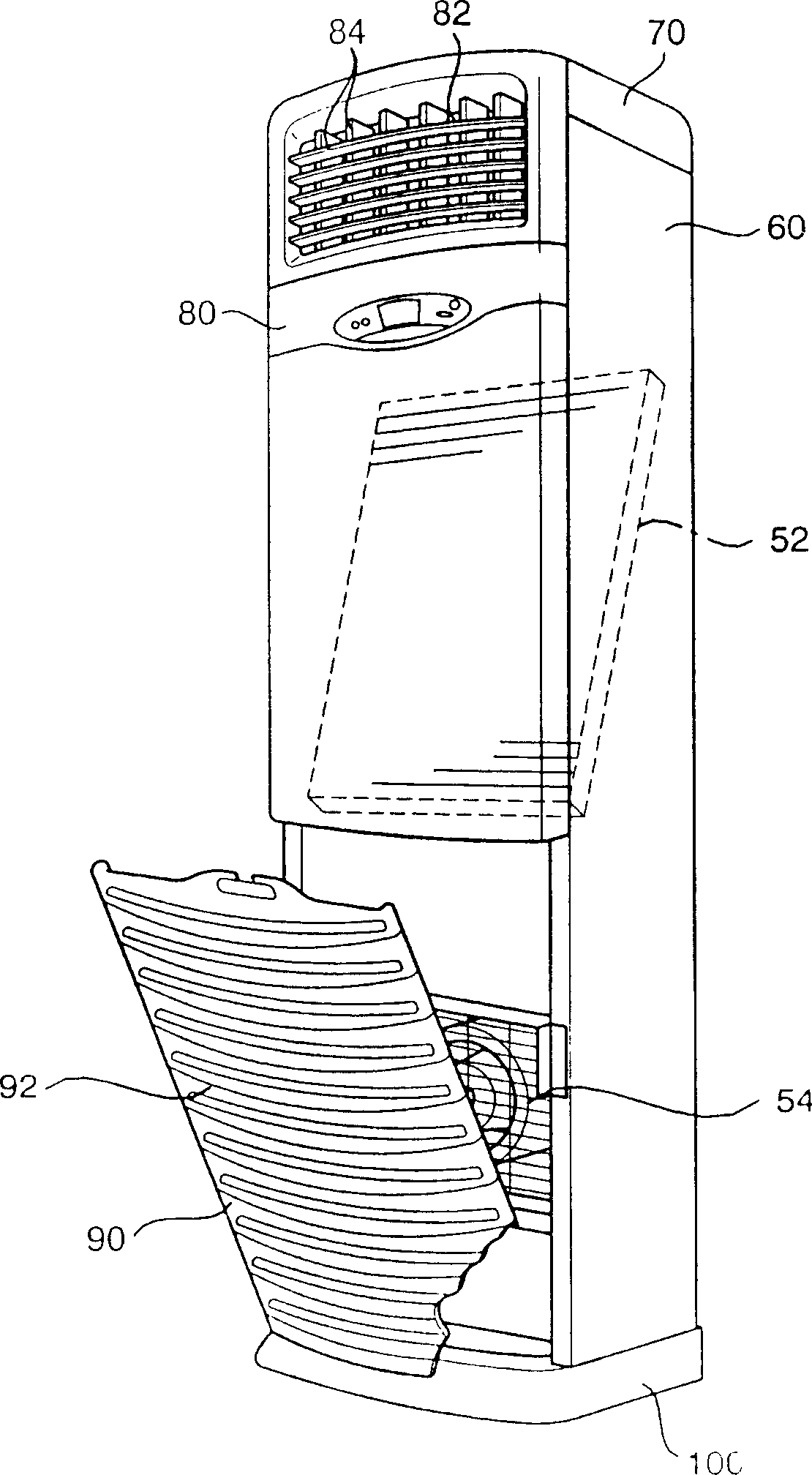

[0016] In order to further understand the content, characteristics and effects of the present invention and give examples of the following embodiments, the air conditioner of the present embodiment is as follows: figure 2 As shown, a heat exchanger 52 and an air blower 54 are provided on the front and the open interior of the cabinet 60, the upper end of the cabinet 60 is combined with the upper cover 70, and an air exhaust port 82 is arranged on the front of the upper cover 70 and the upper part of the cabinet 60. The air outlet 82 is equipped with the front upper panel 80 of the wind direction adjustment mechanism 84, and the lower front of the cabinet 60 is provided with a suction louver 90 for sucking in the air inlet 92 of indoor air, and the bottom of the cabinet 60 is provided with a support cabinet 60 and a foil suction louver 90 base 100 etc. to constitute the air conditioner.

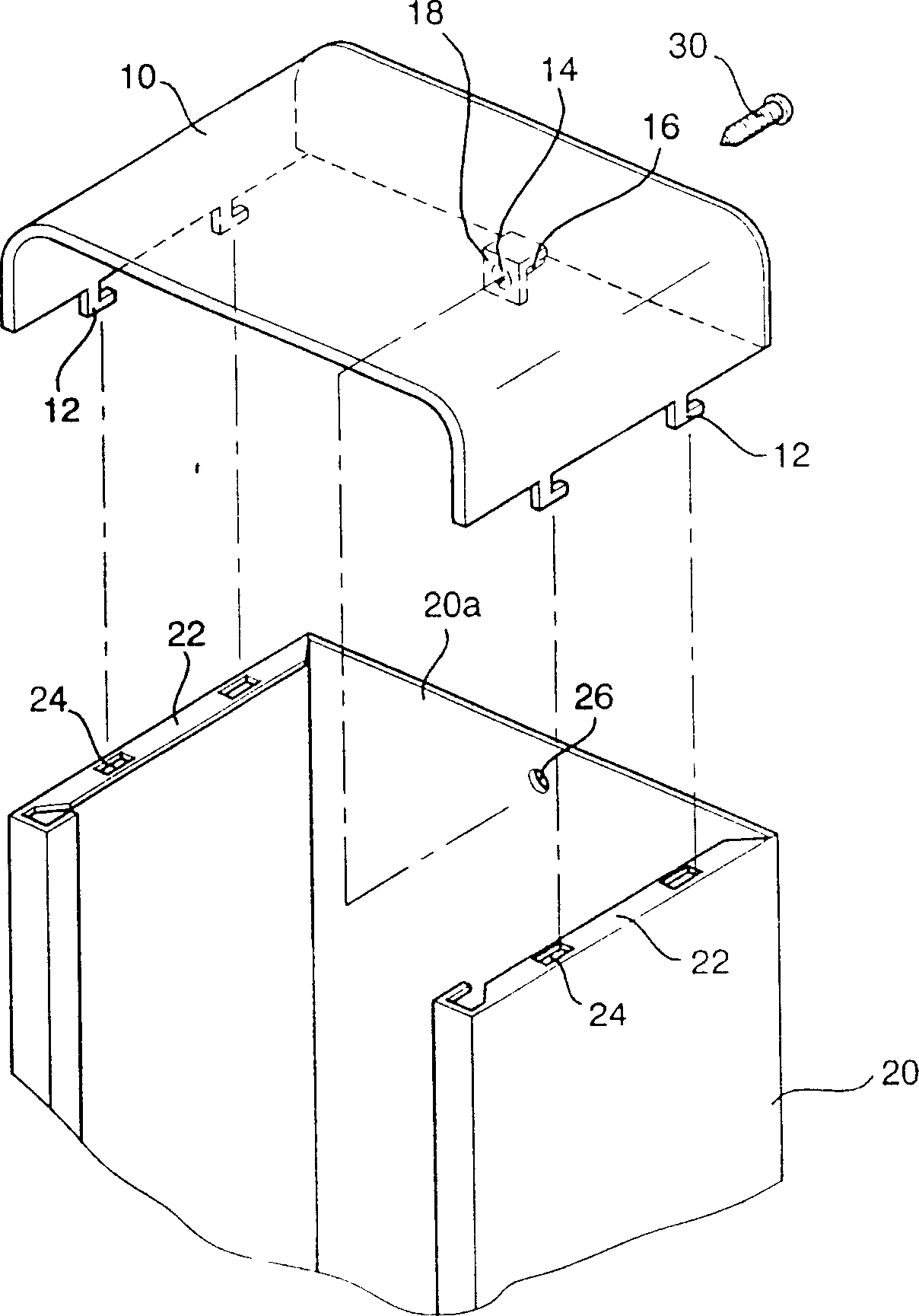

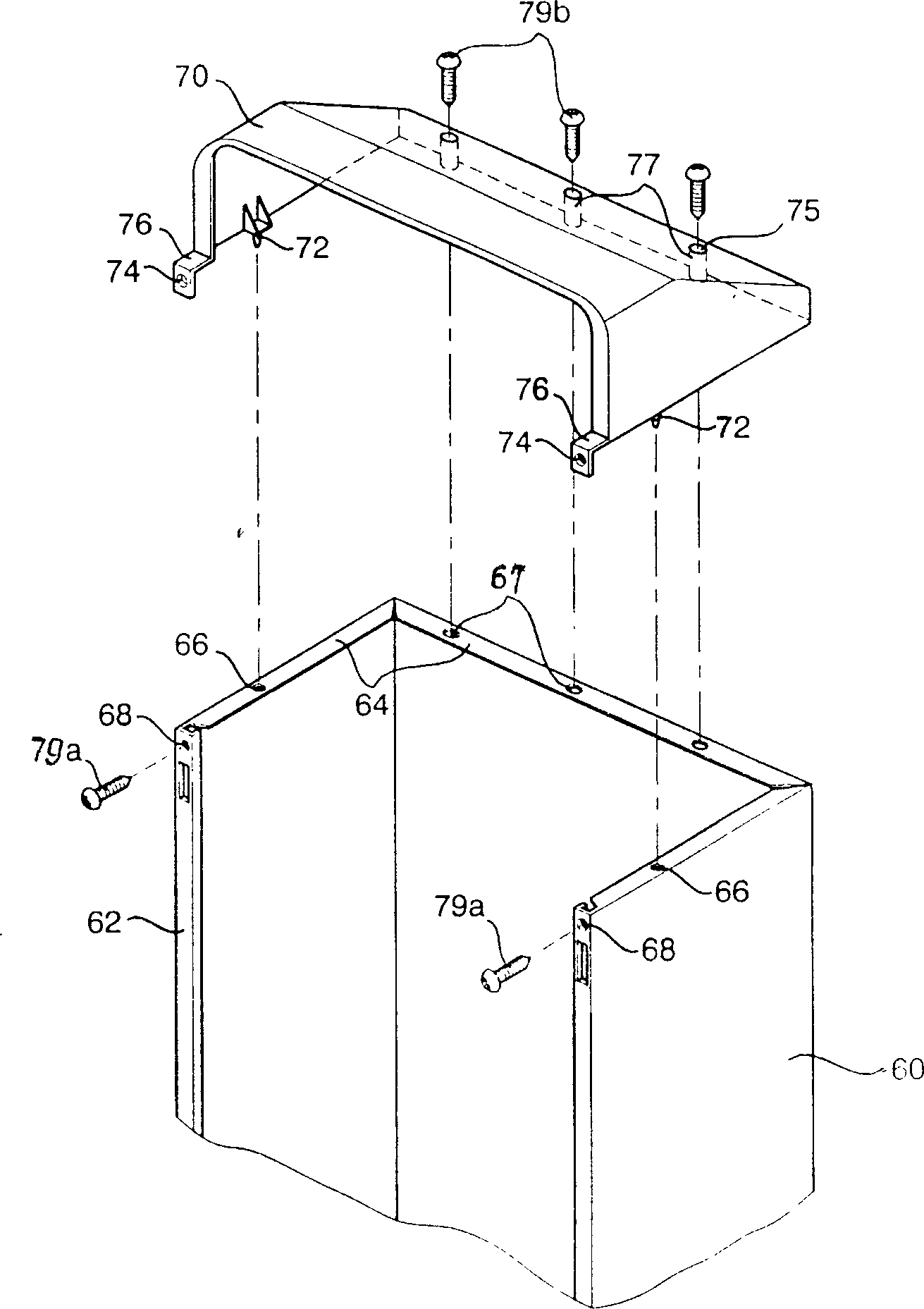

[0017] The above chassis 60 such as image 3 As shown, the front sides of the cabinet 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com