Base plate fixing device

A technology for fixing devices and substrates, applied in ion implantation plating, metal material coating process, coating, etc., can solve problems such as fragmentation, abnormality, and crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

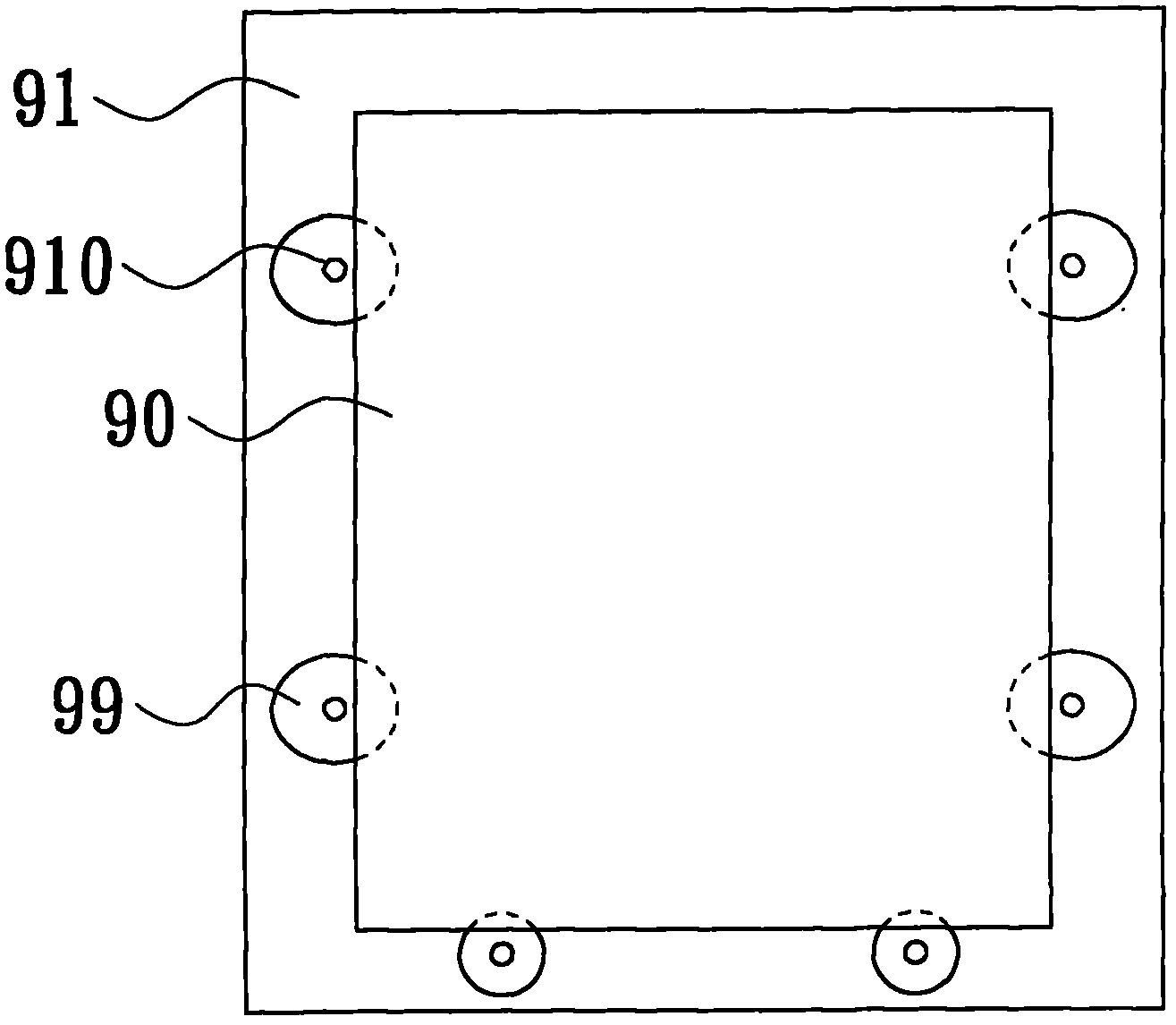

[0037] See Figure 2A-2E , is the top view and side view of the substrate fixing device developed to improve the lack of conventional devices in this case, and the Figure 2A It can be seen from the upper view in the figure that the substrate fixing device of this case uses the bearing seat 11 to carry the substrate 10, and the bearing seat 11 is larger in area than the substrate 10 and has an outer ring part 111, and there are multiple transparent parts on both sides of the outer ring part 111. The hole 110 has a groove 19 around the through hole 110 . As for the lower side of the carrier seat 11 in the figure, a contact portion 131 is provided for abutting against the substrate 10 and fixing the substrate 10 to the carrier seat 11. As for the substrate 10, it can be a glass substrate, a light-transmitting substrate or a semiconductor substrate. and other substrates.

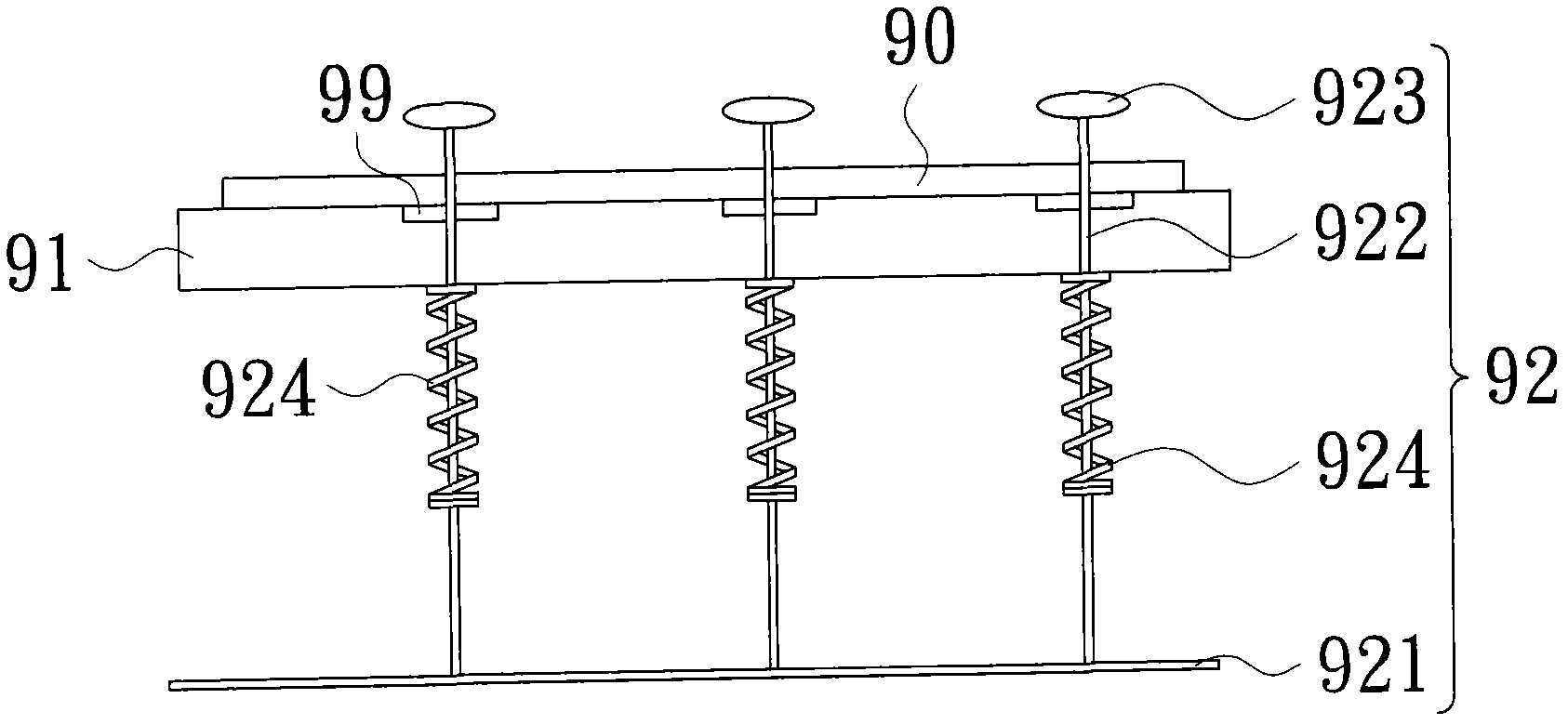

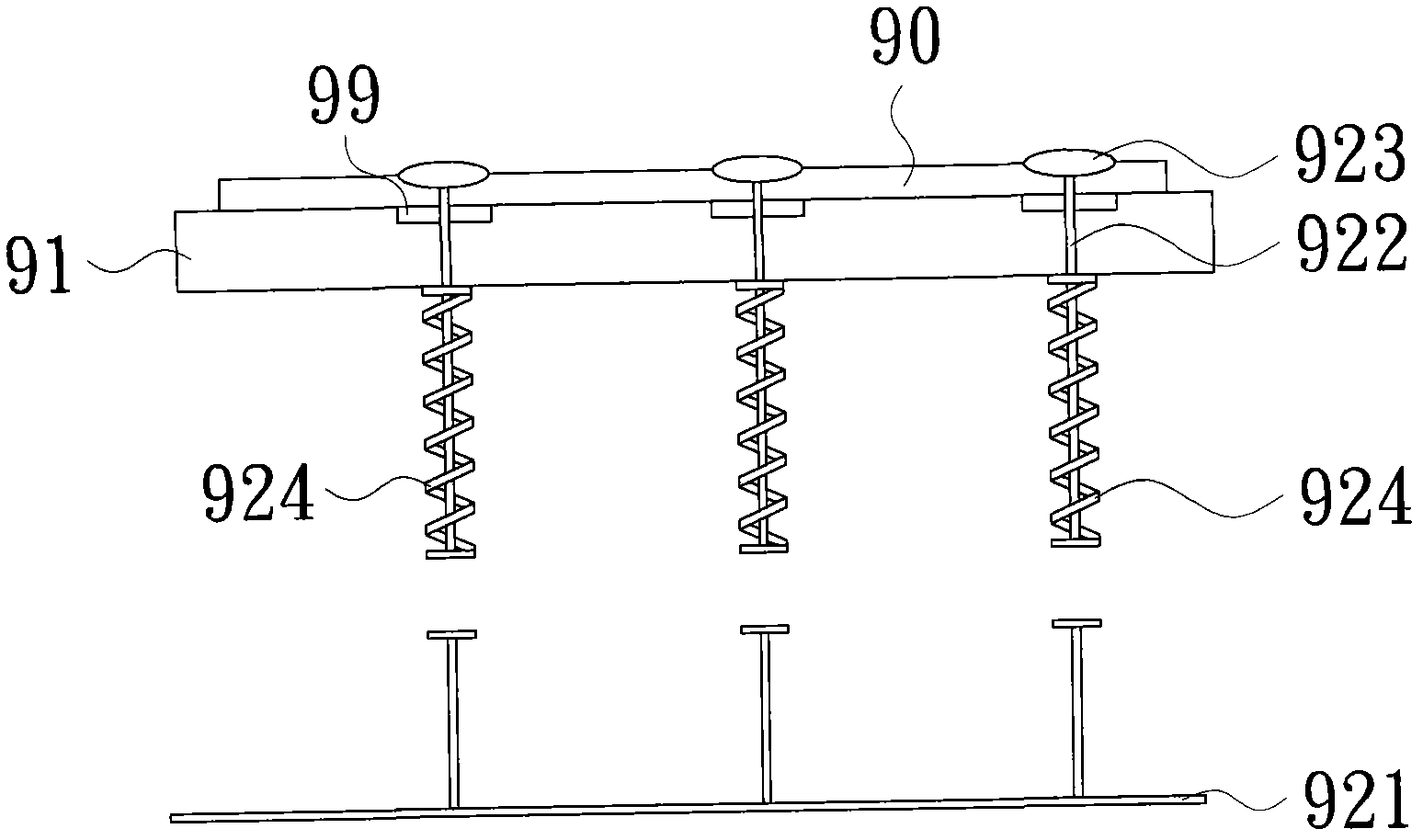

[0038] see you again Figure 2B As shown in the schematic side view, the plurality of through holes 110 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com