Gushing water flow pulsator washing method

A pulsator and water flow technology, applied in the laundry field of washing machines, can solve the problems of increased design and production complexity of washing machines, insufficient use of water flow in washing machines, and entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

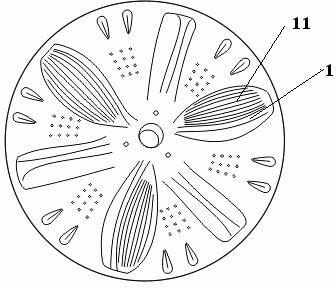

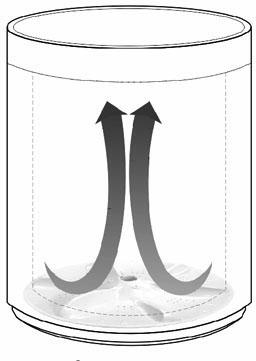

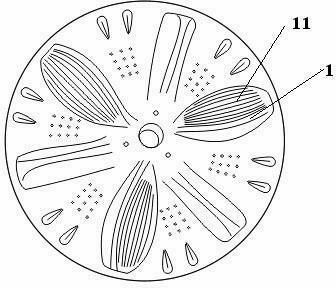

[0007] A small washing machine comprises a pulsator, the middle part of the pulsator protrudes, the height of the blade 1 on the pulsator is 8 cm, the side 11 of the blade 1 is a curved surface, and there are reinforcing ribs on the curved surface; the washing method is to use the pulsator equipped with the pulsator When washing clothes in the washing machine, the pulsator rotates forward for 2.5 seconds, stops for 3 seconds, reverses for 2 seconds, stops for 3 seconds, and cycles according to this program.

[0008] A larger type of washing machine includes a pulsator, the middle of the pulsator is raised, the height of the blade protrusion on the pulsator is 12 cm, the side of the blade is a curved surface, and there are reinforcing ribs on the curved surface; the washing method is to use the washing machine equipped with the pulsator For laundry, the pulsator rotates forward for 3 seconds, stops for 3.5 seconds, reverses for 2.5 seconds, stops for 3.5 seconds, and cycles acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com