Hoisting prefabricated part of embedded small hoisting ring group

A technology of prefabricated components and hoisting rings, which is applied in the construction of buildings, construction, and the processing of building materials, etc., can solve the problems of stacking, loading and transportation of components, increasing the cost of component production and transportation, and weakening the effective section of prefabricated components. , to achieve the effect of increasing the number of bicycles transported, reducing losses and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

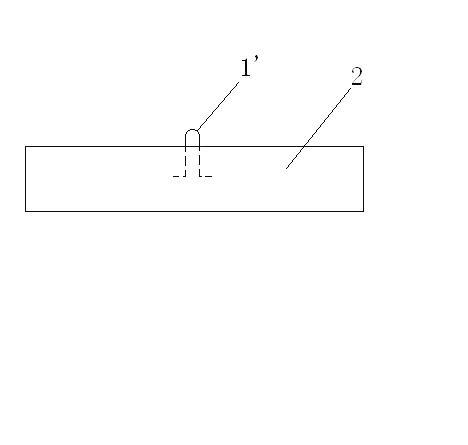

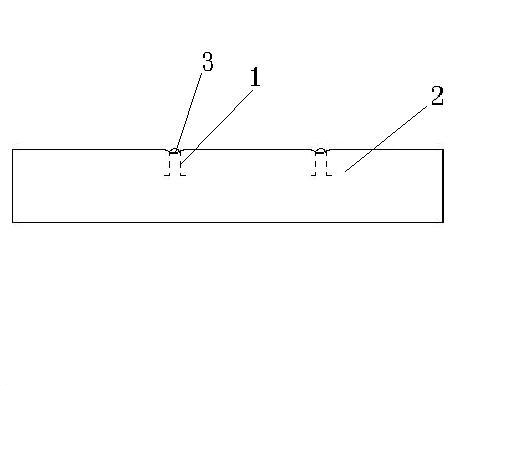

[0028] Embodiment 1: A prefabricated component hoisted by a group of pre-embedded small rings (see image 3 , Figure 4 ), which includes a concrete prefabricated component 2, two suspension ring grooves 3 evenly distributed in the horizontal direction on the concrete prefabricated Inside, the top of the small suspension ring 1 is located in the suspension ring groove 3, and the top of the small suspension ring 1 is on the same level as the upper surface of the prefabricated concrete component 2.

Embodiment 2

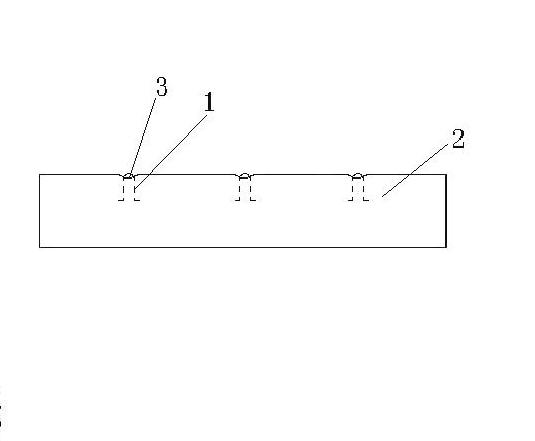

[0029] Embodiment 2: A prefabricated component hoisted by a group of pre-embedded small rings (see Figure 5 , Image 6 ), which includes a concrete prefabricated component 2. Three suspension ring grooves 3 are evenly distributed in a single horizontal row on the concrete prefabricated component 2. Each suspension ring groove 3 is provided with a small suspension ring 1. The root of the small suspension ring 1 is set on the concrete prefabricated component. 2, the top of the small suspension ring 1 is located in the suspension ring groove 3, and the top of the small suspension ring 1 is 5cm lower than the upper surface of the concrete prefabricated component 2.

Embodiment 3

[0030] Embodiment 3: A prefabricated component hoisted by a group of pre-embedded small rings (see Figure 7 ), it includes a concrete prefabricated component 2, and four suspension ring grooves 3 are evenly distributed in a rectangular shape on the concrete prefabricated component 2, and each suspension ring groove 3 is provided with a small suspension ring 1, and the root of the small suspension ring 1 is set on the concrete prefabricated component 2, the top of the small suspension ring 1 is located in the suspension ring groove 3, and the top of the small suspension ring 1 is on the same level as the upper surface of the prefabricated concrete component 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com